drying

-

Closed-Loop Spray Dryer Features Online Monitoring and Self-diagnostic Control Functions

The closed-loop spray drying system uses an inert gas (generally N2) as the carrier to transfer heat, used in a in a closed cycle. it is beneficial for conserving the heat carrier, recovering organic solvents, preventing atmospheric pollution from toxic substances, and avoiding material oxidation.

Email Details -

DPL-200 Top Spray for Granulation and Drying Functions Bottom Spray For Coating Functions

The automatic production and automatic cleaning formulas of the equipment support variable process control, and the process parameters of each stage can be set independently to meet the needs of customers' customized processes

Email Details -

DPL-300 All-in-One Fluid-Bed Processor:Top-Spray Granulation, Bottom-Spray Coating, Instant Drying

The equipment adopts PLC full-automatic control. All operations can be automatically completed by setting process parameters according to user requirements. It can print all process parameters, with true and reliable original records, fully complying with GMP requirements for pharmaceutical production.

Email Details -

Hot

CSD-5 Spray Dryer Suitable for Producing Powdery and Granular Products from Liquid Raw Materials

① Adopt rotary cutting air inlet technology and adjustable volute to ensure uniform distribution of materials and no reverse top. ② The heat source can be electric heating, steam heating or a combination of various heating methods to ensure high efficiency and low consumption.

Email Details -

Hot

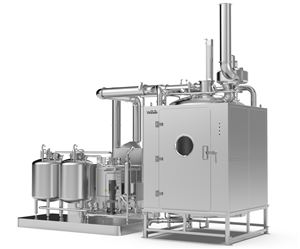

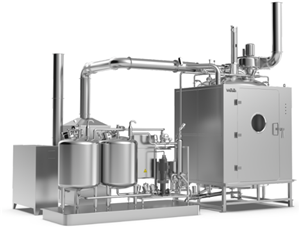

ZLXHD-200 Multifunctional Bin Cleaning Machine Hopper Washing Machine with Big Sight Window for Better Viewing

The equipment is a machine integrating cleaning, drying and cooling. With high degree of automation and simple operation, it adopts HMI and PLC control during the whole course, which can comply 21CFR Part11 requirements.

Multifunctional Bin Cleaning Machine Hopper Washing Machine Big Sight Window Cleaning Drying and CoolingEmail Details -

Spray dryer for drying liquid to powder

Product Features: 1. Adopt rotary cutting air inlet technology and adjustable volute to ensure uniform distribution of materials and no reverse top. 2. The heat source can be electric heating, steam heating or a combination of various heating methods to ensure high efficiency and low consumption. 3. The whole machine is compact and beautiful in structure, easy to operate, the hot air chamber can be disassembled and cleaned, and the inlet air temperature can be adjusted and controlled. 4. Air jacket cooling system is adopted for the drying chamber and top parts to prevent the material from being melted and hung on the chamber 5. The inner wall of the drying chamber adopts an air rotary blowing device to eliminate or reduce the sticking phenomenon. 6. The powder collecting system adopts dehumidification air blowing cooling technology to cool the product and prevent moisture absorption and agglomeration. 7.It with GMP production requirements, dry air cleanliness is better than 100,000 grades, easy to clean, and product quality is stable.

Email Details -

Hot

Multifunctional Fluid Bed Granulator (DPL-300) for Pharmaceutical Chemical Food Industry with Advanced Drying Solutions

Production capacity Granulation and drying:130-300kg/batch Bottom spray coating:114-190kg/batch

Email Details -

ZLXHD Series Multifunctional Bin Cleaning Machine with Integrated Hopper Cleaning and Drying

▲Providing uniform cleaning standard for the cleaning bins and easily making the traceability and certification of the cleaning process ▲lmproving the production efficiency ▲Reducing labor intensity of workers integrating cleaning, drying and cooling functions ▲Adopting HMl and PLC control during the whole process, which is with high degree of automation and simple operation, complying 21CFR Part11 requirements

Multifunctional Bin Cleaning Machine Multifunctional Hopper Cleaning and Drying Integrated Hopper Cleaning and Drying High-Performance Bin Cleaning EquipmentEmail Details -

CSD series Powder Centrifugal Drying Machinery Spray Dryer Tower Open Circuit Spray Drying System

Spray dryer is a widely used process in powder forming and drying industries. It is suitable for producing powdery and granular products from liquid raw materials such as solutions, emulsions, suspensions, and pastes. Therefore, spray dryer is an ideal process when the particle size distribution, residual moisture content, bulk density and particle shape of the finished product must meet precise criteria. Spray dryer is suitable for food, pharmaceutical, energy and chemical fields.

Email Details