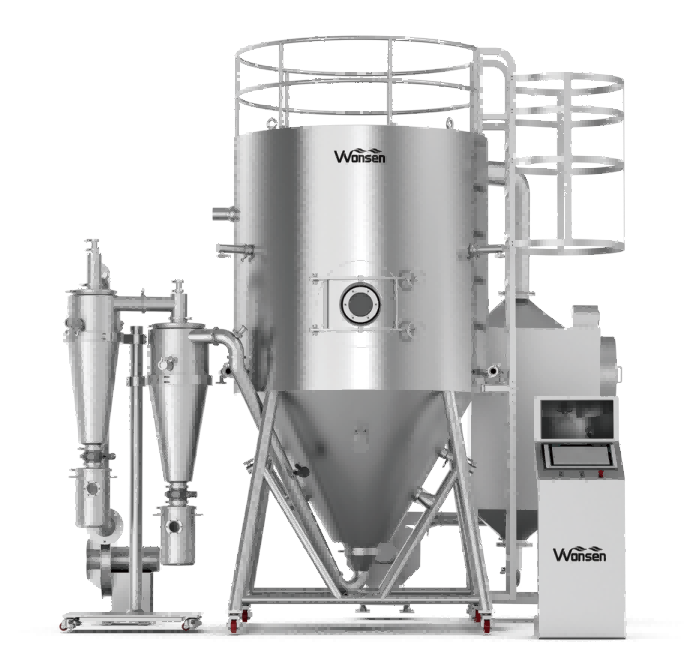

Closed-Loop Spray Dryer Features Online Monitoring and Self-diagnostic Control Functions

- Wonsen

- China

- 120 days

- Strong

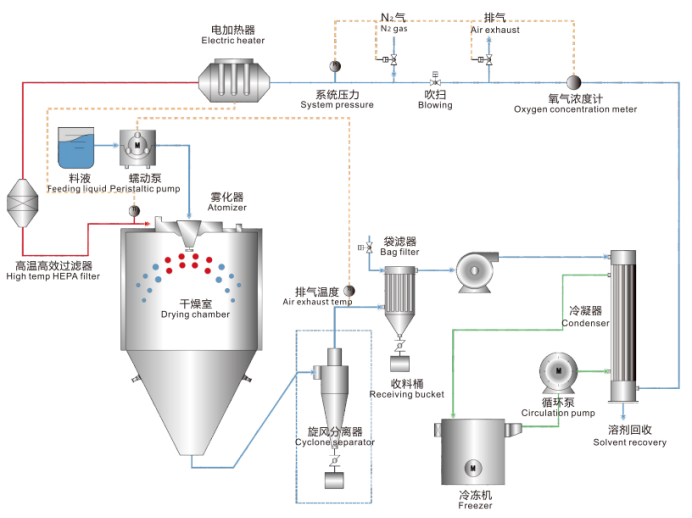

The closed-loop spray drying system uses an inert gas (generally N2) as the carrier to transfer heat, used in a in a closed cycle. it is beneficial for conserving the heat carrier, recovering organic solvents, preventing atmospheric pollution from toxic substances, and avoiding material oxidation.

Closed-Loop Spray Dryer Features Online Monitoring and Self-diagnostic Control Functions

Features

1. The closed-loop spray drying system uses an inert gas (generally N2) as the carrier to transfer heat, used in a in a closed cycle. it is beneficial for conserving the heat carrier, recovering organic solvents, preventing atmospheric pollution from toxic substances, and avoiding material oxidation.

2. It features online monitoring and self-diagnostic control functions for temperature, pressure, and oxygen content, ensuring the safety of the drying process and a high degree of intelligent control.

3. The system can perform low-temperature drying operations below 100℃, making it suitable for temperature-sensitive materials.

4. lt is easy to achieve aseptic and dust-free operation.

Process flow diagram of closed circuit two-point collection system

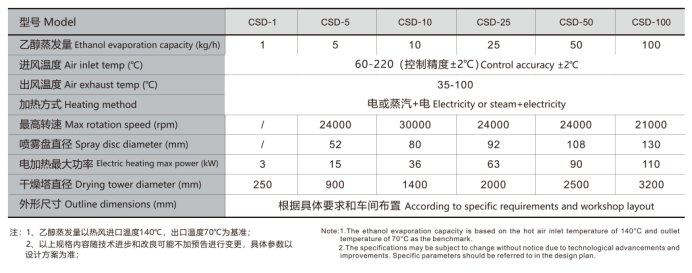

Technical Parameters

R&D Machine

Top-Opening Spray Dryer

Closed-Loop Spray Dryer

R&D Testing Equipment

The Wonsen R&D Testing Center is equipped with a complete set of testing and analysis instruments for feeding liquid and powder materials, as well as professional testing personnel, to meet customers’ needs for sample preparation and confirmation of drying characteristics.

Wonsen Closed - Loop Spray Drying System is a cutting - edge, highly efficient, and environmentally - friendly technology. It is designed to optimize the drying process by recycling and reusing materials, thus achieving significant energy savings and reducing waste. This innovative system ensures consistent product quality while minimizing environmental impact, making it a preferred choice for modern industrial applications.