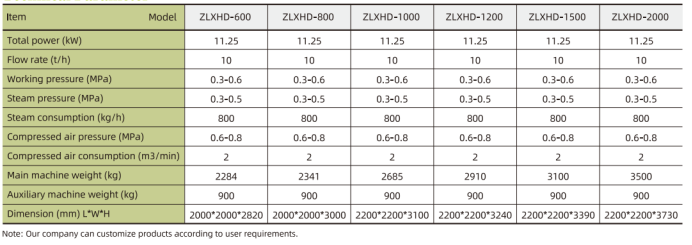

ZLXHD Series Multifunctional Bin Cleaning Machine with Integrated Hopper Cleaning and Drying

- Wonsen

- China

- 120 days

- Strong

▲Providing uniform cleaning standard for the cleaning bins and easily making the traceability and certification of the cleaning process

▲lmproving the production efficiency

▲Reducing labor intensity of workers integrating cleaning, drying and cooling functions

▲Adopting HMl and PLC control during the whole process, which is with high degree of automation and simple operation, complying 21CFR Part11 requirements

ZLXHD Series Multifunctional Bin Cleaning Machine with Integrated Hopper Cleaning and Drying

Introduction

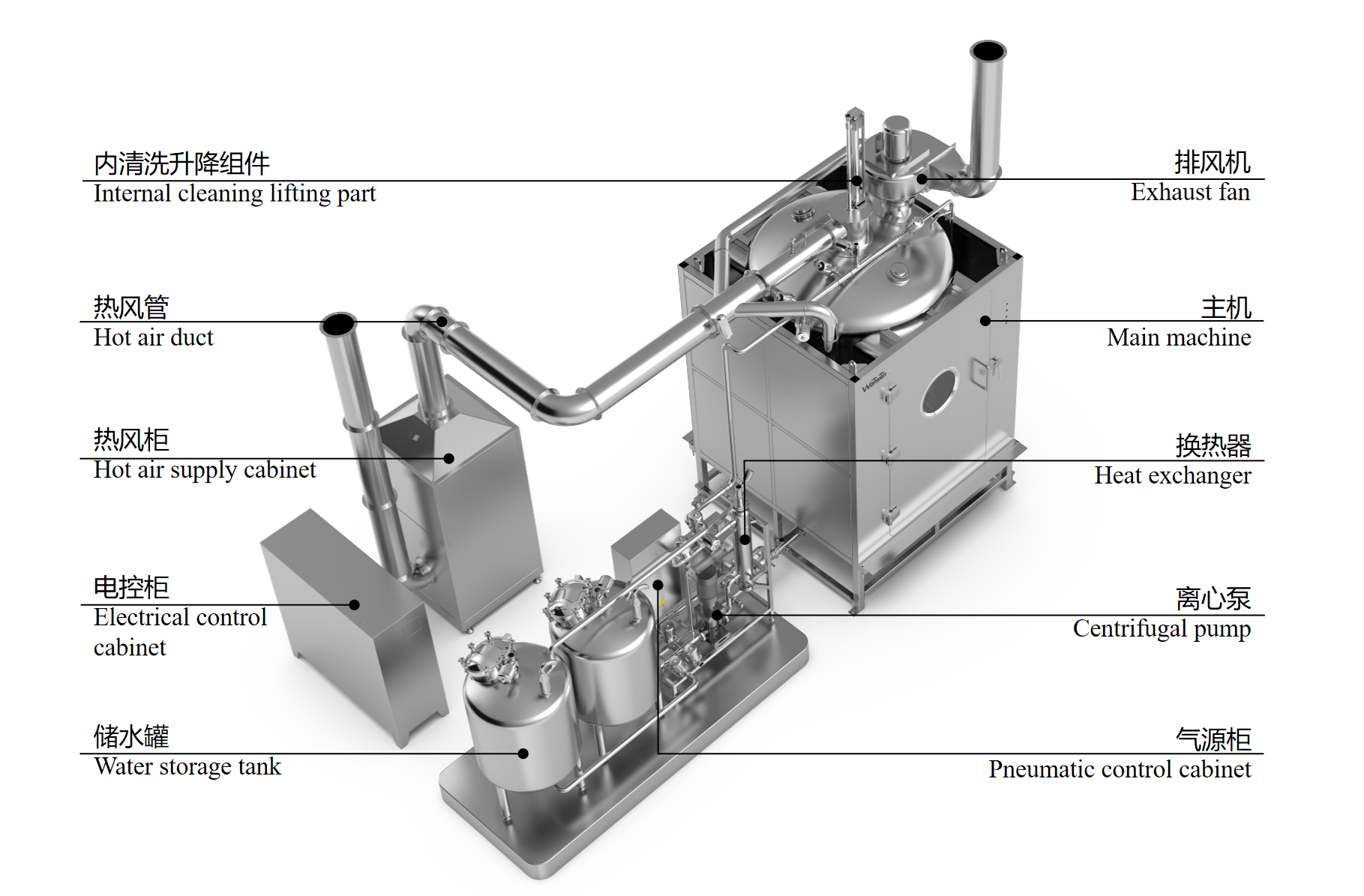

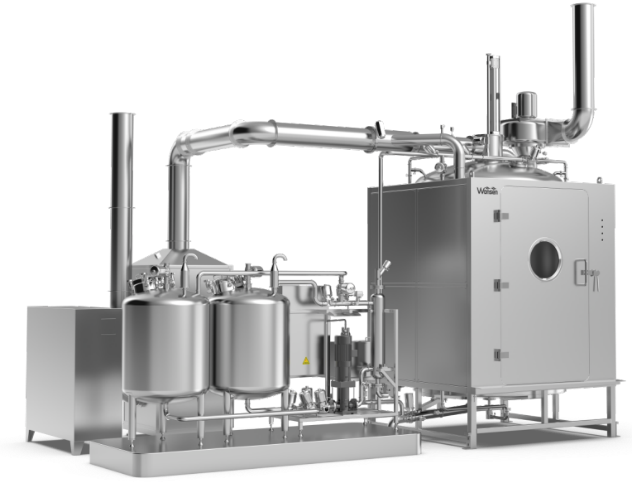

The ZLXHD series Multifunctional Bin Cleaning Machine is mainly used for cleaning stainless steel barrels, IBC transfer hoppers and mixing transfer hoppers in such industries as medicine, chemical industry and food. The machine features rational design, compact structure, stable operation, and user-friendly operation. It can effectively remove foreign matters remaining on the inner and outer surfaces of the hopper to avoid cross contamination of various ingredients during the production. It is an indispensable machine in enterprises. It is also a necessary machine for the GMP requirements to be met during the production process of solid preparations in pharmaceutical enterprises.

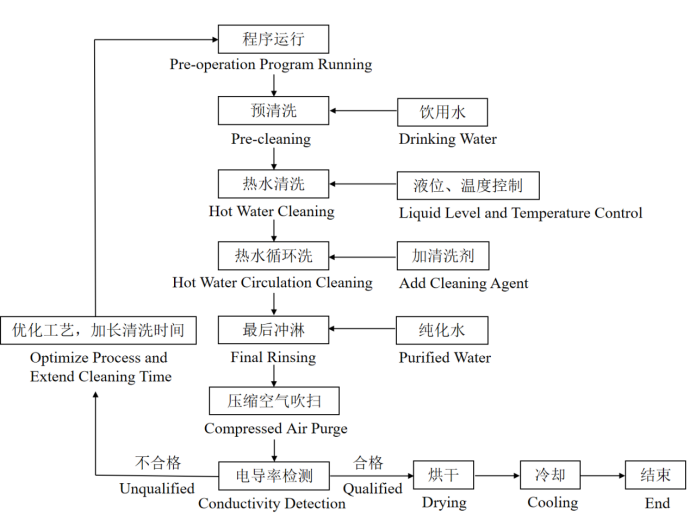

Work principle

Open the inlet door of the cleaning machine, push the hopper into the cleaning station (with the discharge butterfly valve open) and ensure proper positioning. Close the door, set the cleaning parameters as per process specifications, and initiate the automated cleaning cycle. The exterior surfaces are cleaned by nozzles circumferentially arranged within the chamber, while the interior is cleaned by retractable rotating nozzles. Bottom-mounted nozzles target the butterfly valve with high-pressure jets. Upon completion of the cleaning phase, the system automatically initiates the preset drying cycle. The equipment powers off only after all programmed cycles are successfully executed. Open the outlet door, push out the cleaned hopper and transfer them to the storage station for future use.

Features

1) PLC Control System: Fully automated operation based on user-defined parameters, including customizable cleaning and drying cycles with automatic data logging. All process data is recorded in real-time, ensuring compliance with CGMP requirements for traceability and documentation.

2) Integrated Hopper Cleaning & Drying: Streamlined operation with fully automated cycles.

3) Premium Construction: Crafted entirely from 304 stainless steel for durability and aesthetic appeal.

4) High-Efficiency Cleaning: Rapid and thorough hopper cleaning reduces labor costs and processing time.

5) Thorough Cleaning Performance: Ensures complete removal of residues and contaminants, eliminating risks associated with manual cleaning oversights and ensuring compliance with GMP standards.

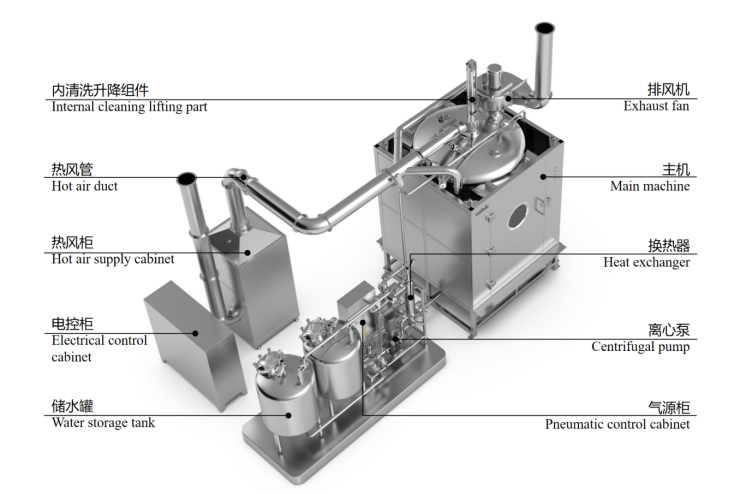

6) Modular Design & Custom Configuration: Comprising four core components—the main unit, pump station, air treatment system, and control panel—the system layout can be tailored to meet specific technical requirements and installation space constraints.

7) Automated Control System: Upon hopper positioning and chamber door closure, the system initiates the pre-programmed cleaning cycle. Following completion, the hopper automatically proceeds to the hot-air drying cycle, until the entire process is completed.

8) Self-Sufficient Heating: Equipped with steam heat exchanger heating and optional electric heating, eliminating the need for an external hot water supply.

9) Separate Water Systems: Isolated purified water and drinking water circuits prevent cross-contamination.

10) Sanitary Components: Features vertical multistage centrifugal pump (with optional sanitary centrifugal pump) and pneumatic diaphragm pump to meet strict hygiene standards.

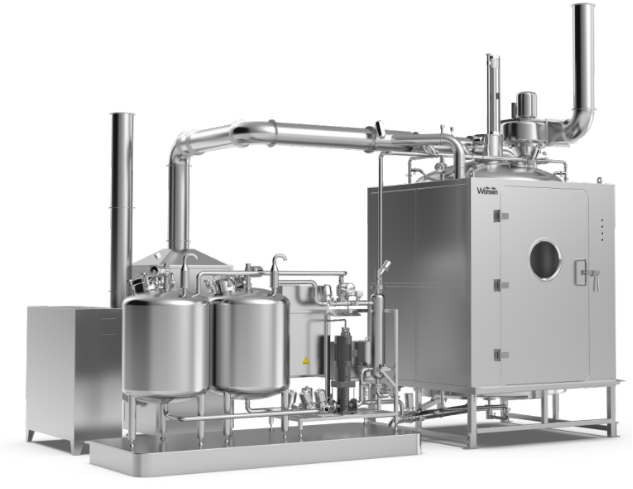

Structure

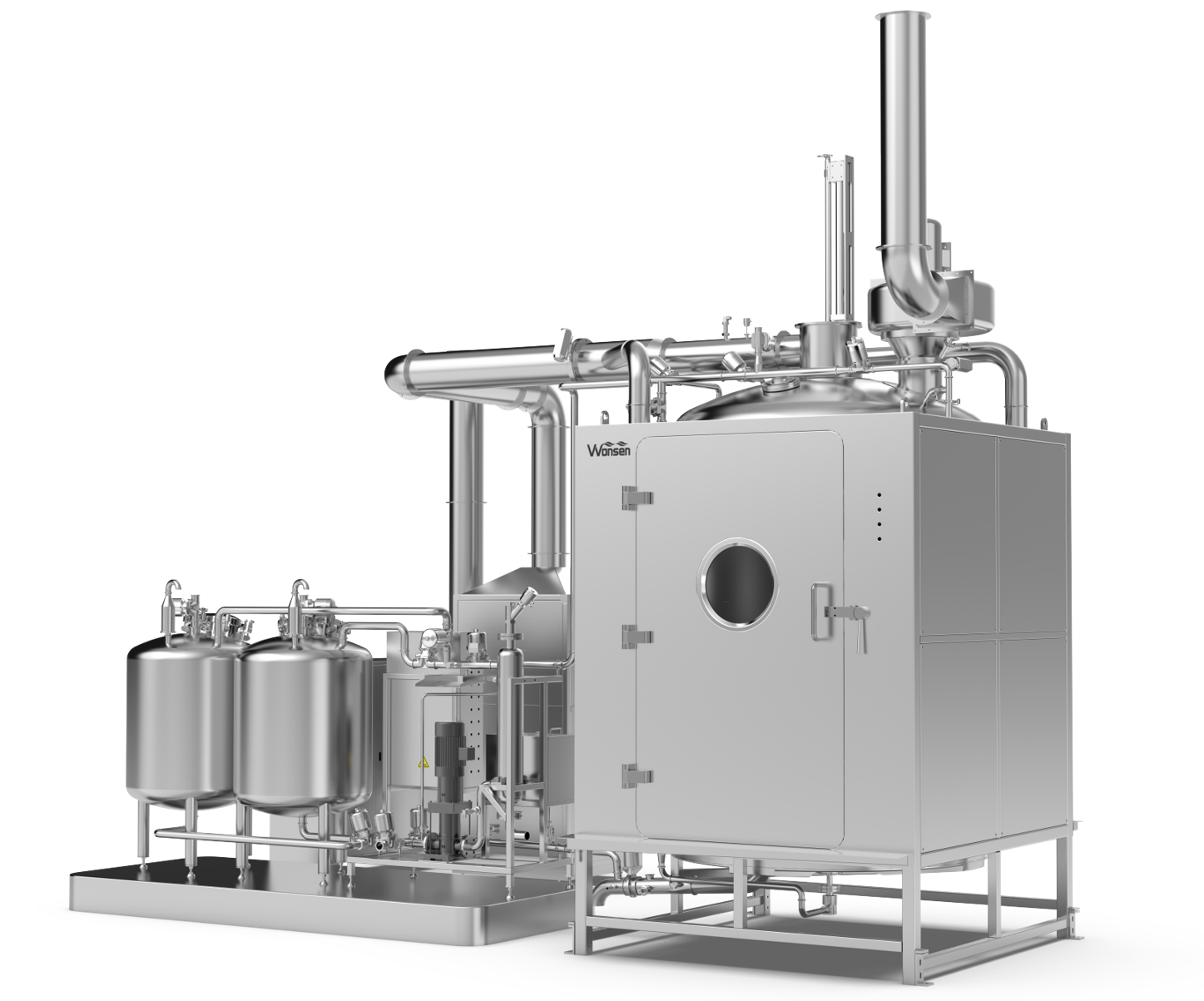

Technical parameter