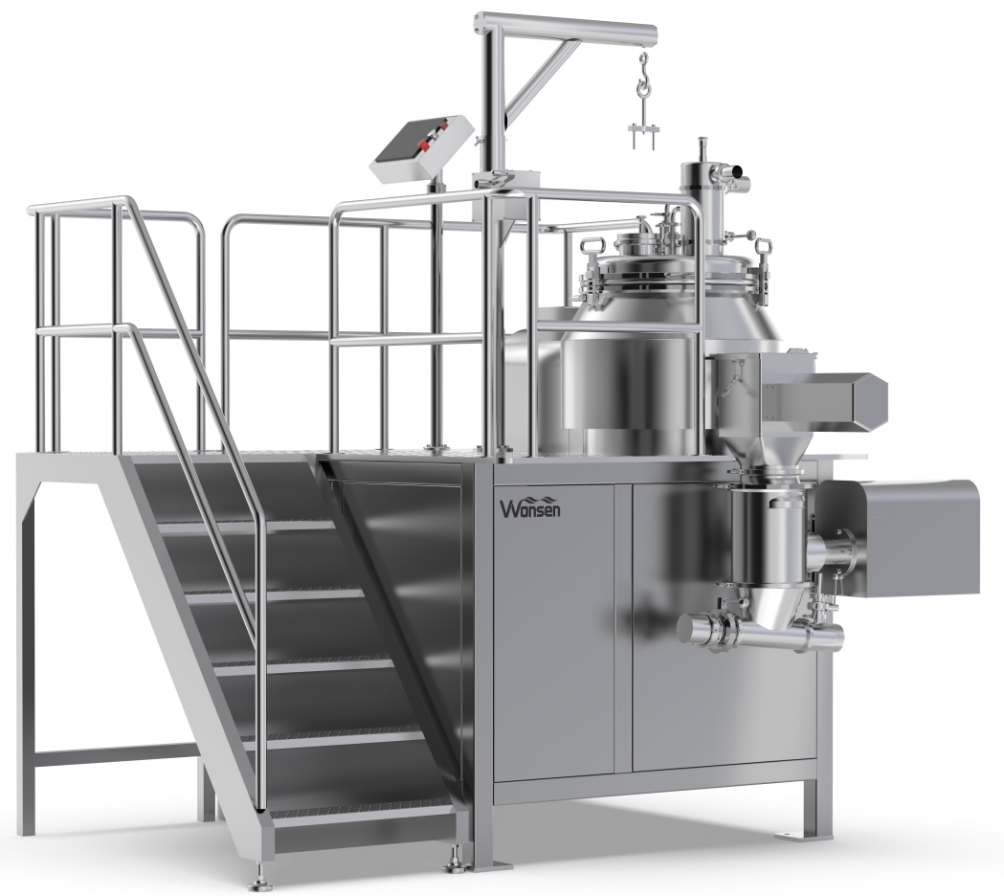

SHLG-1300 Homogeneous Granulation High Shear Mixer Granulator Effective Capacity 1300L

- Wonsen

- China

- 120 days

- Strong

Effective capacity:1300L

Load capacity:288~576 kg/batch (calculated by 0.6g/cm³)

384~768 kg /batch(calculated by 0.8g/cm³)

Main functions and process

The SHLG series High Shear Mixer Granulator adopts PLC programming control, VFD stepless speed regulation, touch screen real-time input and real-time display, can complete mixing, humidification, granulation process at one time, high intelligence integrating water, electricity, gas and light It is mainly suitable for the new granulation process used in the pharmaceutical, food and feed industries, and also for the mixing of chemical dry powder.

Equipment structure and working principle

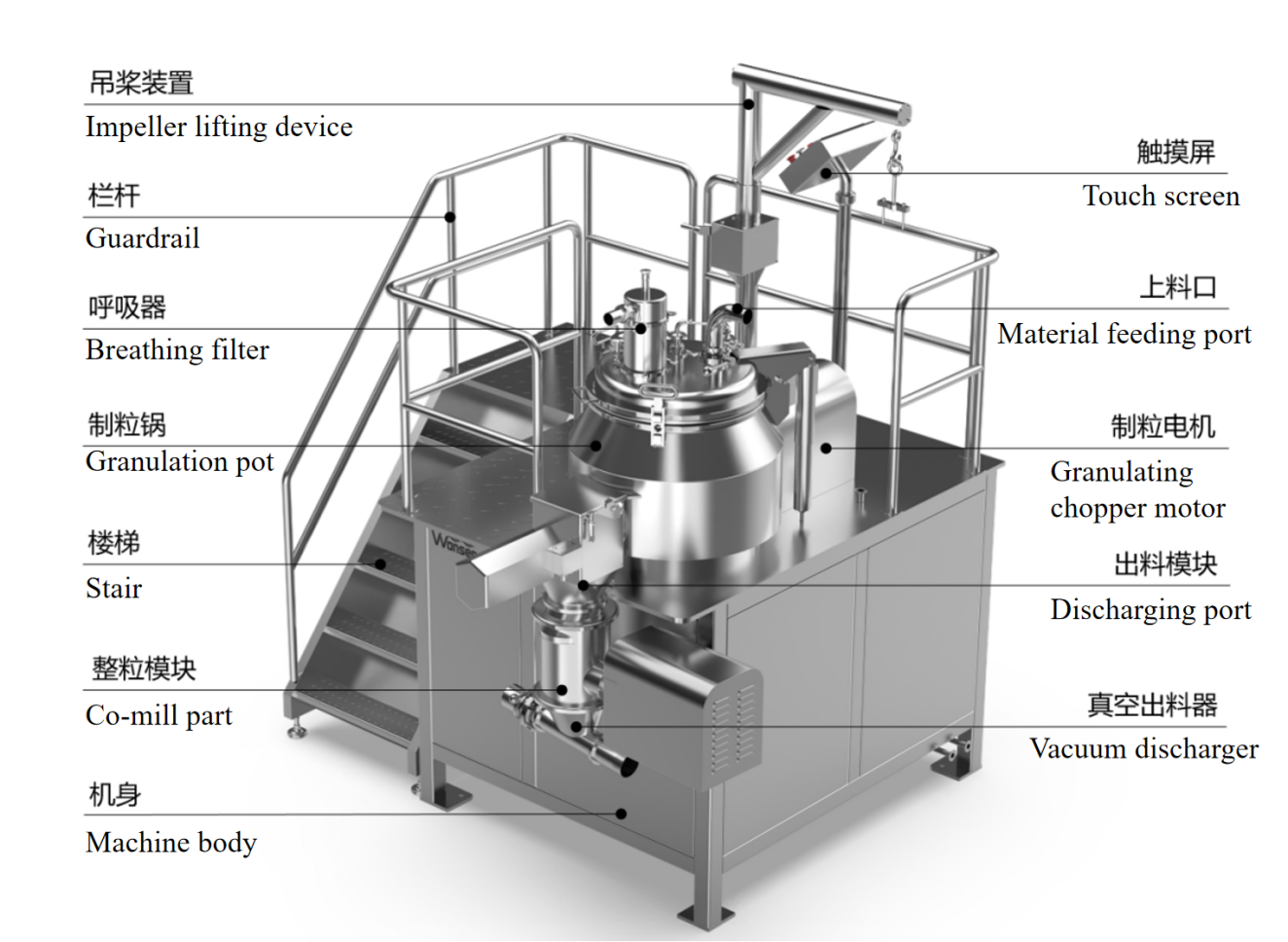

The High Shear Mixer Granulator mainly consists of machine rack, stairs, guardrails, mixing impeller lifting device, material pot and discharge parts, mixing impeller and its transmission device, granulating chopper and its transmission device, cone mill (option), electrical control system, pneumatic control system, etc. As shown in following Figure.

Working principle: After the powdered material enters the mixing container, it is first thoroughly mixed by rotating the bottom mixing impeller, and then injected with adhesive through a pressure spraying to turn the dry powder into a moist soft material. At the same time, uniform granules are made under the dual action of the mixing impeller and the side wall granulating chopper.

Features

1) Complete set of electrical components from internationally renowned brands, adopting Siemens PLC and touch screen, and Schneider frequency converter for speed adjustment;

2) The granulation knife adopts a Christmas tree-shaped structure, the stirring paddle adopts a new three-leaf structure, and a combined seal of mechanical seal and air seal is used;

3) Innovative sprocket drive, which improves stress deformation caused by machining tolerances and facilitates installation and disassembly;

4) Equipped with a stirring paddle lifting device to ensure production safety (equipped for rapid mixer granulator with a volume of 200L and above);

5) The granulation cylinder is equipped with a power-assisted opening device, which saves labor and ensures production safety (equipped for rapid mixer granulator with a volume of 100L and above);

6) The cylinder cover and cylinder body, as well as the discharge port and rapid mixer granulator, adopt airbag seal design with good sealing effect; when the sealing pressure is insufficient, interlock control will stop production and give an alarm;

7) The stirring paddle, granulation knife, and granulating knife (with the granulating knife) are added with closed-loop speed control, which detects the actual speed of the shaft and displays it on the screen; the speed is accurate, not affected by load or motor speed error; it also has the function of monitoring abnormal speed and alarming in case of coupling failure;

8) The main machine is equipped with a conical slurry adding hopper and a manual ball valve; an optional pressure slurry adding tank + spray gun (or solution mixing tank + peristaltic pump + spray gun) can be configured to realize automatic slurry adding with no residue and accurate slurry adding measurement (with a flow meter or ultra-low platform scale);

9) The main machine is equipped with a vacuum feeding interface, which can be connected to a vacuum feeder or a vacuum source to realize automatic feeding;

10) Reserved cleaning pipelines, which can be connected to the water source of the cleaning machine for CIP cleaning;

11) The mixing and granulation time meets the process requirements of corresponding solid preparations (generally 6-10min/batch);

12) The granulation yield is >99%;

13) The automatic production and automatic cleaning formulas of the equipment support variable process control, and the process parameters of each stage can be set independently to meet the needs of customers' customized processes;

14) Can be configured with electronic signature, data storage and audit trail functions, and can print process data;

15) Optional time, current or torque as the end-point determination;

16) The equipment has passed the EU CE certification;

Technical parameter

No. | Item | Parameter(SHLG-1300) | |

1 | Effective capacity | 1300L | |

2 | Load capacity | 288~576 kg/batch (calculated by 0.6g/cm³) | |

3 | Mixing power | 75kW | |

4 | Mixing impeller speed | 15~100rpm | |

5 | Granulating power | 15kW | |

6 | Granulating chopper speed | 300~2800 rpm | |

7 | External conditions | Power supply | 380V/50Hz three-phrase five-wire |

Compressed air pressure | 0.6-0.8MPa | ||

Compressed air consumption | 1m3/min | ||

Compressed air inlet tube spec. | 12*8 mm | ||

Cleaning fluid pressure | 0.3MPa | ||

Max liquid consumption | 3m3/h | ||

Cleaning water inlet pipe spec. | Φ25 mm Clamp K51 | ||

Feeding tube spec. | Φ63 mm Clamp K77.5 | ||