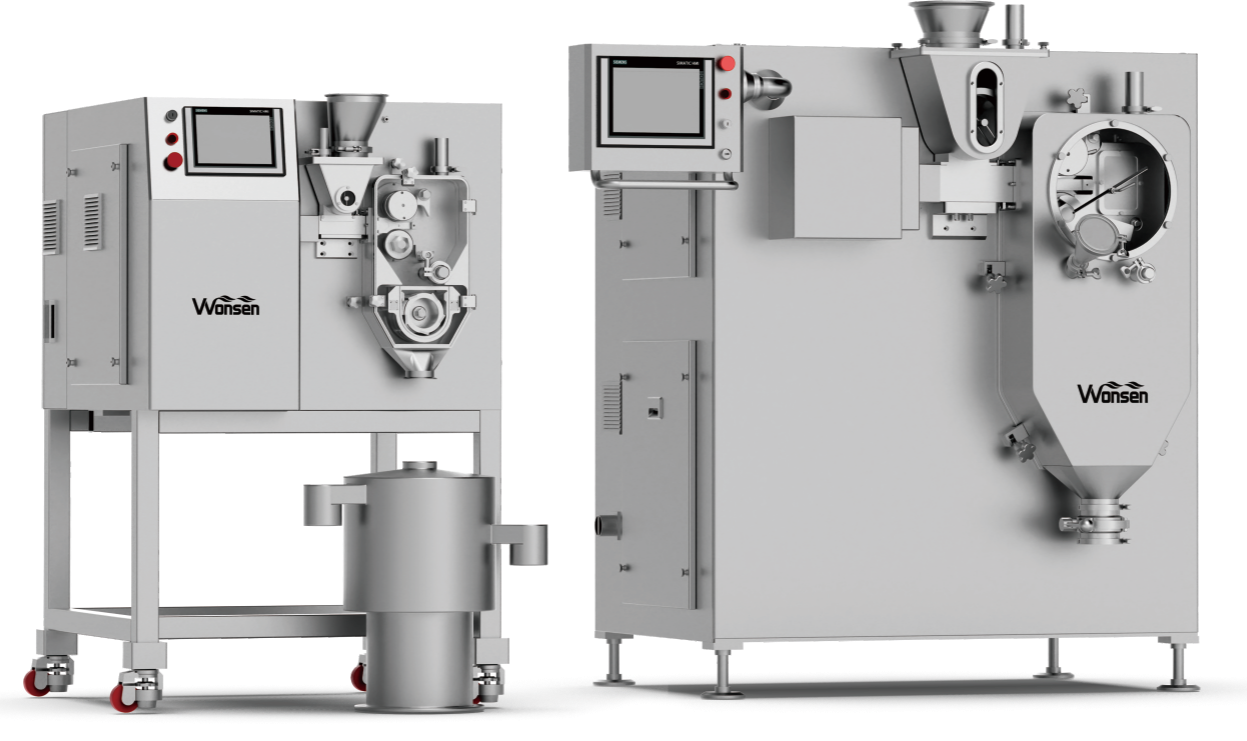

LG-30 Dry Granulation Granule Closed Production Line with 50kg/h Capacity

- Wonsen

- China

- 120 days

- Strong

LG-30 Dry Granulation Granule Closed Production Line with 50kg/h Capacity Fully enclosed, fully automated, and contamination-free production.

Main functions and process

LG series Roller Compactor adopts continuous loading, discharging, integrates compacting, pre-crushing and granulation functions, directly compacting powder into granules. It is especially suitable for granulation of materials which are thermo-sensitive and humidity sensitive, easily broken down or agglomerated. It has been widely used in pharmaceuticals, food, chemicals and other industries. In the pharmaceutical industry, granules made by roller compactor can be directly pressed into tablets or filled into capsules.

Work principle

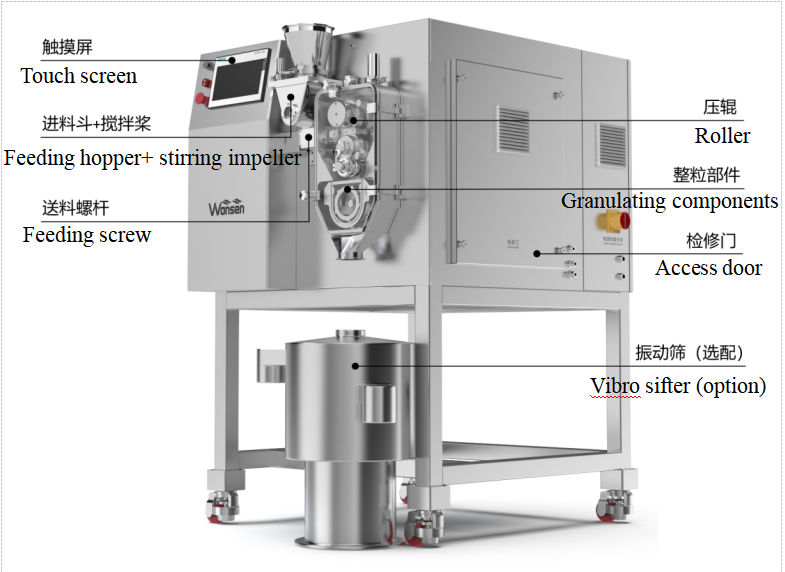

After the material enters the feeding hopper, it is stirred by the stirring impeller and pushed by the screw. A pair of rollers that move in opposite directions are used to press the powdered material into a sheet shape, increasing its specific gravity. Then, it is crushed by the granulating mechanism to obtain qualified material.

Features

1) PLC automatic control, color touch screen human-machine interface is friendly, easy to operate.

2) After the material enters the feeding hopper, it is stirred by the mixing impeller and enters the screw feeder, which is fed by the screw and the rotation speed is continuously adjustable;

3) Two parallel rollers are specially treated to increase loading capacity and strength;

4) The roller chamber is completely closed and its compression is observed through the organic glass panel;

5) The roller adopts water circulation cooling structure, in order to prevent thermal deterioration of special materials;

6) Rollers with different surface shapes can be quickly replaced according to process requirements;

7) The main drive motor (roller) adopts frequency conversion speed regulation, the rotation speed can be continuously adjusted, and has the upper and lower limit control of rotation speed;

8) Parts in contact with the material shall be made of stainless steel or food-grade polymer materials;

9) The pressure applied to the roller and the roller clearance can be displayed and adjusted on the touch screen;

10) The milling device can change the screen according to the need to obtain different mesh number of material granules;

11) By changing the speed ratio between the screw feeding and the roller, granules of different thickness and hardness (or specific gravity) can be obtained;

12) With the setting of machine parameters and working mode, and the function of password protection, failure alarm and help menu;

13) The machine equipped with horizontal twin screw feeding and unique cantilever type design, which improves the range of materials treated and the success rate and yield of granulating;

14) Water-cooled roller, the production of materials will not affect the performance of the material due to temperature rise;

15) The rollers are made of special stainless steel by special process, and its surface has high hardness and wear resistance;

16) The whole machine is of high quality stainless steel construction, all material contact parts are 316L, which fully meets the GMP requirements of drug production;

17) The feeder is designed with a vacuum exhaust port, which can effectively discharge the air in the material when the screw is feeding, so that the feeding is more compact. Unique vacuum exhaust system, does not cause equipment temperature rise.

18) The working area is separated from the transmission area to achieve clean and closed production from powder to granules, effectively preventing dust and cross contamination, and all parts in contact with materials are easy to disassemble and clean.

Structure

Technical parameter

No. | Parameter name | Parameter content (LG-30 Roller Compactor) |

1 | Roller size (mm) | 120×40 |

2 | Granule size (mm) | 0.18-2.0 |

3 | Loading capacity (kg/h) | 0.1-50kg/h (our capacity is calculated based on lactose, final capacity based on user own material characters) |

4 | Mixing speed (rpm) | 0-70 |

5 | Screw feeding speed (rpm) | 0-140 |

6 | Roller rotation speed (rpm) | 0-27 |

7 | Milling rotation speed (rpm) | 0-140 |

8 | Cutting rotation speed (rpm) | 0-200 |

9 | Max compacting force of the roller (kN/cm) | 25 |

10 | Screw feeding power | 0.75 |

11 | Roller motor power(kW) | 2.2 |

12 | Milling motor power (kW) | 0.55 |

13 | Mixing motor power(kW) | 0.18 |

14 | Cutting motor power(kW) | 0.4 |

15 | Pump station motor power (kW) | 0.55 |

16 | Cutting motor power (kW) | 0.4 |

17 | Referenced outline dimension (mm) | 1692*1150*1883 |

18 | Referenced total weight (kg) | 900 |

19 | One-time yield (0.18-2.0mm granules) | ≥65% |

20 | Final yield | ≥98% |

21 | Power supply | 3PH/380V/50Hz |

22 | Compressed air pressure | 0.4-0.6Mpa |

23 | Compressed air consumption | 580L/min |

24 | Compressed air hose tube | Φ12*8 |

25 | Referenced total weight (kg) | 900 Kg |

26 | Referenced outline dimension (mm) | Refer to final drawing(can be customized) |

No. | Name | Parameter |

ZKQ-150 Pneumatic Vacuum Feeder | ||

1 | Capacity | 150 kg/h |

2 | Air Consumption | 180 L/min |

3 | Power | 0.014 kW |

4 | Power supply | 1PH/220V/50Hz |

5 | Air pressure | 0.4-0.6 MPa |

6 | Compressed air tube | Φ10*Φ6mm,PU tube |

7 | Noise | ≤ 90 dB(A) |

8 | Referenced dimension | According to the actual drawing |

9 | Referenced machine weight | 8kg |

No. | Name | Parameter(ZKQT-150 Lifting Pneumatic Vacuum Feeder) | |

1 | Capacity | 150kg/h (Referenced 0.35g/cm³) | |

2 | Max Lifting height | 2000 mm | |

3 | 2300 mm | ||

4 | Power | 0.014 kW | |

5 | Noise | ≤90dB(A) | |

6 | External condition | Power supply | 1PH/220V/50Hz |

7 | Compressed air pressure | 0.4-0.6 MPa | |

8 | Compressed air consumption | 180 L/min | |

9 | Compressed air tube | Φ10*Φ6mm,PU管 | |

10 | Referenced machine weight | 8 kg | |

11 | Referenced dimension size | Details see drawing | |

No. | Name | Parameter(ZS-400-2S Vibro Sifter) |

1 | Capacity | 50 kg/h |

2 | Machine power | 0.18kW |

3 | Motor rotation speed | 1450 rpm |

4 | Power supply | 3PH/380V/50Hz |

5 | Amplitude (of vibration) | 3-5 mm |

6 | Screen layer | 2 layers with 3 discharging ports |

7 | Noise | <75dB(A) |

8 | Referenced dimension size | Details see drawing |