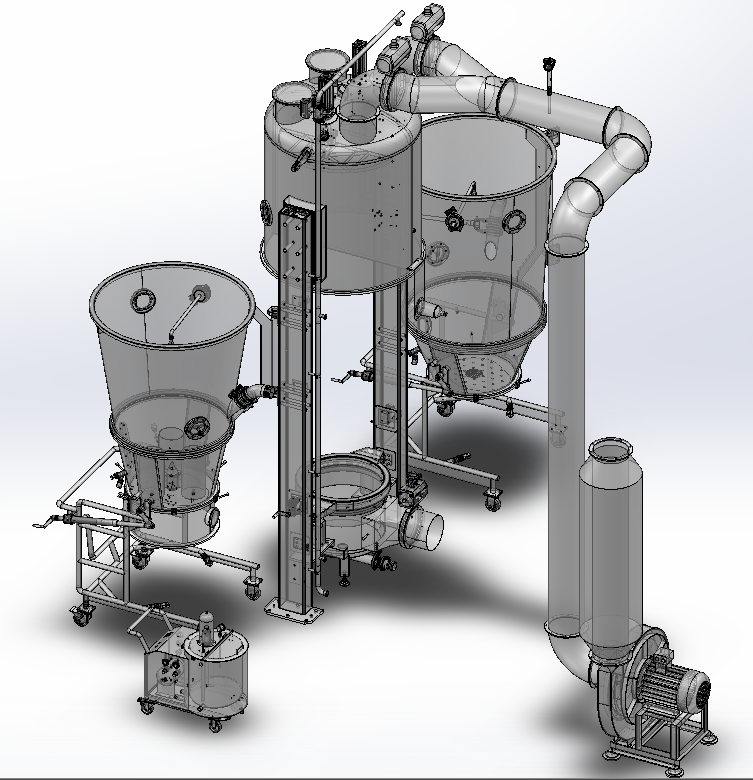

Multifunctional Fluid Bed Granulator (DPL-300) for Pharmaceutical Chemical Food Industry with Advanced Drying Solutions

- Wonsen

- China

- 120 days

- Strong

Production capacity

Granulation and drying:130-300kg/batch

Bottom spray coating:114-190kg/batch

Introduction

DPL multifunctional fluid bed granulator is a new model successfully developed by our company by extensively absorbing and digesting foreign advanced technologies and combining practical experience. This equipment integrates top-spray granulation and bottom-spray coating functions, and simultaneously has multiple functions such as mixing, drying, granulation, coating, etc., and is widely used in pharmaceutical, food, chemical and other industries.

The equipment adopts PLC full-automatic control. All operations can be automatically completed by setting process parameters according to user requirements. It can print all process parameters, with true and reliable original records, fully complying with GMP requirements for pharmaceutical production.

Work principle

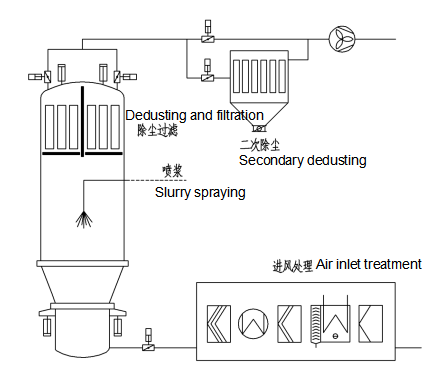

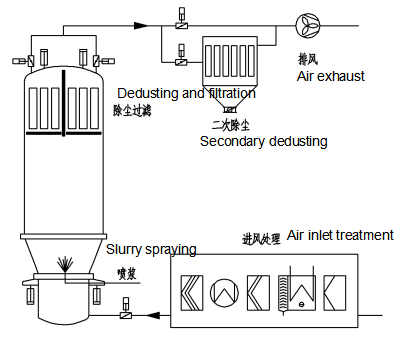

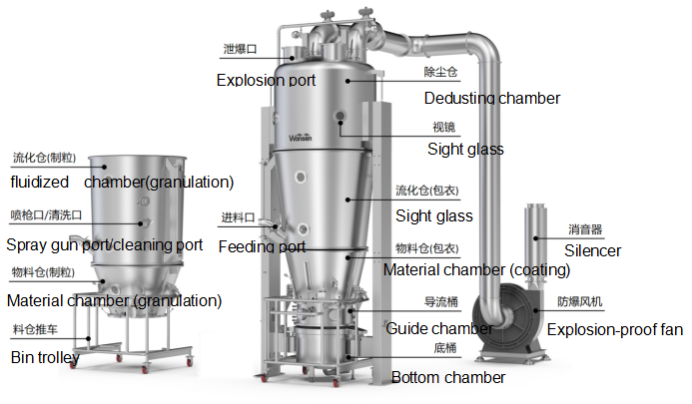

The multifunctional fluid bed granulator consists of a main machine, top-spray system, bottom-spray system, air inlet module, air exhaust module, control system, etc. The top spray is for granulation and drying functions, and the bottom spray is for coating functions. All the above functions are realized on the same fluid bed granulator, and users can choose according to actual production.

Top-Spray Granulation Working Principle Schematic Diagram

Bottom-Spray Coating Working Principle Schematic Diagram

Features

1)Adopting PID control, the air temperature can be arbitrarily set and automatically adjusted within the range of normal temperature - 120℃. Using Siemens proportional valve, on the basis that the Party A provides stable steam and high-quality steam trap, the temperature control accuracy is within ±2℃ of the target value, preventing large temperature fluctuations and improving productivity;

2)The inlet air humidity can reach 11g/kg after surface cooling and dehumidification; with option rotary dehumidifier, the inlet air humidity can reach 5-8g/kg; with option large rotary dehumidifier, the inlet air humidity can reach 3-4g/kg; with option double rotary dehumidifiers, the inlet air humidity can be controlled to ≤1g/kg;

3) The air inlet treatment system adopts G4 primary filter, F8 medium filter, H13 high-temperature resistant high-efficiency filter, and the high-efficiency filter is equipped with a DOP detection port for leak detection test;

4) The primary and medium filters are equipped with differential pressure gauges to detect filter blockage, and the high-efficiency differential pressure analog output signal is displayed on the touch screen;

5) The inlet air is controlled by a proportional valve, which can effectively adjust the negative pressure in the fluid bed granulator to prevent material collapse;

6) The fluidized chamber adopts a conical design, and spray gun nozzles of different heights are designed outside the cavity of the fluidized chamber;

7) The specially designed distribution plate enables more uniform air inlet and more uniform force on granules, resulting in uniform size of the produced granules;

8) The material of the dust removal cloth bag is upgraded from domestic ordinary anti-static non-woven fabric to PTD-3D multi-fiber composite anti-static filter cloth, which is not easy to stick to materials, has good air permeability and is easy to clean;

9) The top of the main machine is designed with directional explosion venting to protect components that are not resistant to pressure impact;

10) The secondary dust removal filtration grade is F9, meeting the national emission standards, with a purification value of less than 20mg/m³ (with option F9+H13 filter, the purification value is less than 10mg/m³; with option F9+H14 filter, the purification value is less than 1mg/m³)

11) A special high-pressure explosion-proof centrifugal fan is adopted to ensure sufficient air pressure under the condition of guaranteed air volume;

12) The equipment can be configured with online cleaning function to clean the bottom chamber, material chamber, fluidized chamber and dedusting chamber;

13) The automatic production and automatic cleaning formulas of the equipment support variable process control, and the process parameters of each stage can be set independently to meet the needs of customers' customized processes;

14) The control system is equipped with five-level password authorization, which is authorized and managed for monitors, operators, process personnel, maintenance personnel and managers respectively;

15) The air volume control accuracy of the control system is ±5%, supporting functions such as audit trail, data recording and printing;

16) The granulation end point can be judged by detecting the moisture content of materials;

17) Meeting the EU CE standards.

Structure

Technical parameter

Working volume:

Granulation and drying: 260-600L

Bottom spray coating: 228-380L

Production capacity:

Granulation and drying:130-300kg/batch

Bottom spray coating:114-190kg/batch

For specific technical parameters, please leave a message for inquiry.