lifting

-

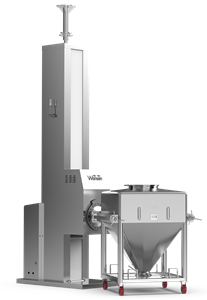

HLT One-Pillar Bin-to-Bin Mixer: Dust-Free Lifting, Recipe-Driven Validation Included

Featuring fully automated lifting, mixing, and lowering functions, this high-efficiency system accommodates multiple container sizes for versatile batch processing.

Email Details -

Hot

ZTH-2000 Fully Automatic Lifting Mixer Bin Blender Capable of Handling Interchangeable Mixing Bins of Various Volumes

① HMI and PLC control, can display English/Chinese ② 5 level password protection for operation ③ Bin-in-place detection: Automatic positioning of bin after completion of mixing time, vertical with discharging valve at bottom

Email Details -

HZTD Single Columm Lifting Mixing Bin

(1)Equipped with 4 casters (2 fixed and 2 swivel) for easy movement. (2)Discharging port: Standard manual butterfly valve. (3)Material: 304/316L (optional). (4)Inner surface: Polished finish; (5)Outer surface: Brushed/sandblasted finish.

Email Details -

CT series Lifting Machine Among Floors with Special Design for Material Transfer among Different Floors

1)Special design for material transfer among different floors 2)Safe and stable performance 3)Labor saving 4)Anti-falling system and safety lock 5)Provided with overload self-protection function and alarm indication function

Email Details -

Hot

HLT Series Single Column Lifting Bin Blender with Simplified Operation and Easy Parameter Adjustment

▲Single column, saving space, with compact structure, stable and reliable operation ▲With interchangeable mixing bins of different volume for various capacity, improving the efficiency, avoiding cross contamination ▲Can customize round mixing bin, with optional mixing chopper and plates ▲The mixing uniformity is over 99%, the loading coefficient is 0.8 and the bin is easy to clean, no dead corner ▲Meet GMP requirements ▲Adopt HMl and PLC auto control system, can optionally comply 21 CFR Part 11 requirements

Bin Blender Single Column Lifting Bin Blender Simplified Operation and Easy Parameter Adjustment customize round mixing binEmail Details -

BGB-F New High-efficiency Coating Machine Optionally Equipped with Tipping Lifting Feeder

▲Overall open design on the front side ▲Easy cleaning, no dead corner ▲Wide install area and maintenance space and pans can be replaceable ▲Unique airbag seal structure, fully enclosed chamber ▲It adopts HM land PLC automatic control system, can optionally comply 21 CFR Part 11 requirements

New High-efficiency Coating Machine Tipping Lifting Feeder Comply 21 CFR Part 11 requirements Film CoaterEmail Details -

High Quality Chemical Powder Blender Machine

1. Changeable bins design for various capacity 2. Human/ machine/ product safety 3. High automation and efficient blending 4. Simple operation and easy to clean

Email Details -

High quality Pharmaceutical tablet blender machine automatic lifting bin blender

1. Changeable bins design for various capacity 2. Human/ machine/ product safety 3. High automation and efficient blending 4. Simple operation and easy to clean

Email Details -

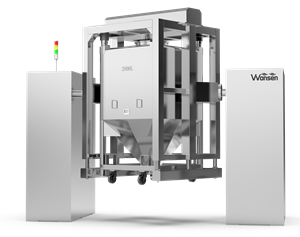

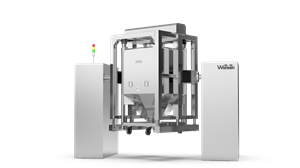

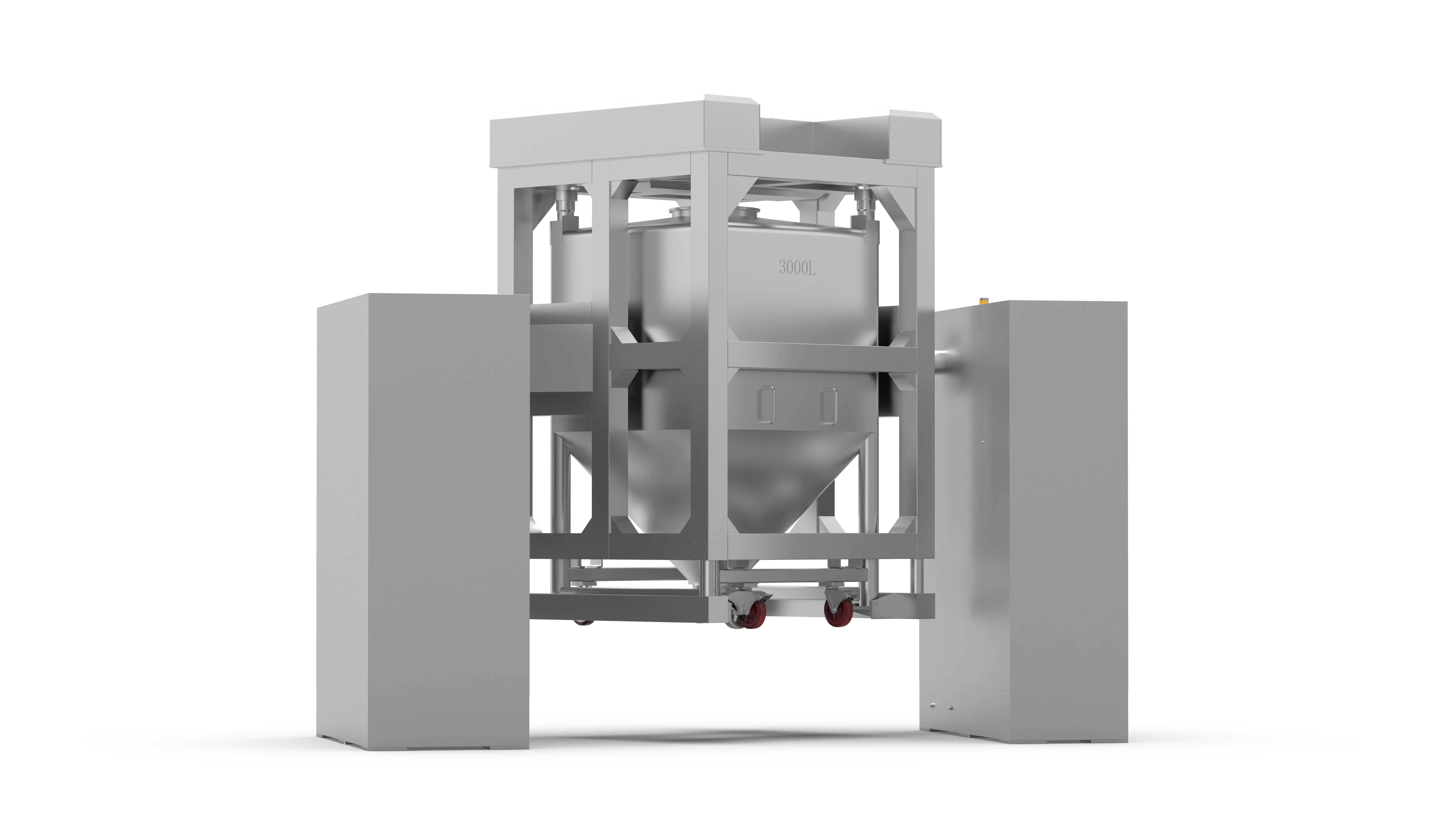

ZTH-3000 360° rotation mixing bin blender lifting machine

1. HMI and PLC control, can display English/Chinese 2. 5 level password protection for operation 3. Bin-in-place detection: Automatic positioning of bin after completion of mixing time, vertical with discharging valve at bottom 4. Key Switch (for main On-Off) 5. Mixing speed and time setting 6. RPM and timer display (to be displayed on HMI) 7. Receipe storage (for mixing time, mixing speed, etc) 8. Monitoring of fault and blocking signals; 9. Monitoring the operation of all mixing programs; 10. Archiving keeping data on the progress of the technological process 11. USB data output 12. Equipped with power shutdown protection: Phoenix UPS 13. Complying 21CFR Part11 requirements

Email Details