HLT One-Pillar Bin-to-Bin Mixer: Dust-Free Lifting, Recipe-Driven Validation Included

- Wonsen

- China

- 120 days

- Strong

Featuring fully automated lifting, mixing, and lowering functions, this high-efficiency system accommodates multiple container sizes for versatile batch processing.

Introduction

The HLT series single column lifting bin blender is widely used in pharmaceutical production for blending powders, powder-granule mixtures, and granules. Featuring fully automated lifting, mixing, and lowering functions, this high-efficiency system accommodates multiple container sizes for versatile batch processing. Ideal for mid-to-large scale pharmaceutical manufacturers, it supports multi-product, multi-batch operations with single-unit flexibility.

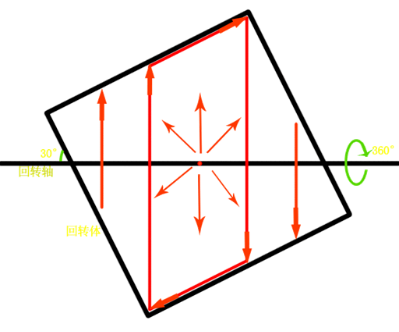

Work principle

The HLT series single-column lifting bin blender performs material mixing by elevating the bin via a vertical column and rotating it around its axis. The offset angle between the bin's symmetrical axis and the rotation arm axis creates intensive three-dimensional movement, generating high shear forces for optimal blending within the closed container.

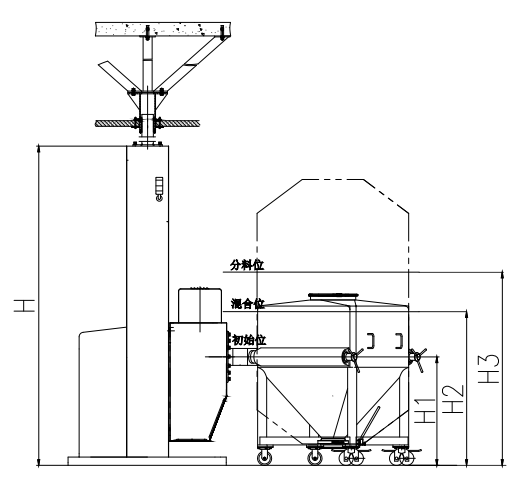

Workflow

1) Load and secure the bin to the rotation arm by tightening both side nuts;

2) Operators exit the safety perimeter and initiate the control system, setting parameters (mixing time/speed);

3) Initiate operation - bin lifts to mixing height and automatic mixing begins;

4) After mixing, the system returns to horizontal position, lowers the bin and stops;

5) Release the locking nuts and transfer the bin to next process.

Features

1) The blender features hydraulic lifting, motor drive and PLC control for simplified operation and easy parameter adjustment;

2) The mixing bin serves both as a feeding container for previous processes and a discharge hopper for subsequent processes (tableting/filling);

3) Achieves mixing uniformity RSD≤3% with loading coefficient 0.3-0.8. The bin features smooth surfaces (internal/external) with dead-space-free design;

4) The control system is responsive with compact structure and stable operation;

5) Equipped with closed-loop speed control displaying actual shaft speed. Maintains precision regardless of load or motor speed variations, with coupling failure detection and speed anomaly alarm;

6) Compatible with multiple bin sizes. Materials can be transferred directly to next process without discharge, improving efficiency while preventing cross-contamination (GMP compliant);

7) After each batch, empty bins are cleaned in dedicated washing areas to maintain cleanroom conditions.

Structure

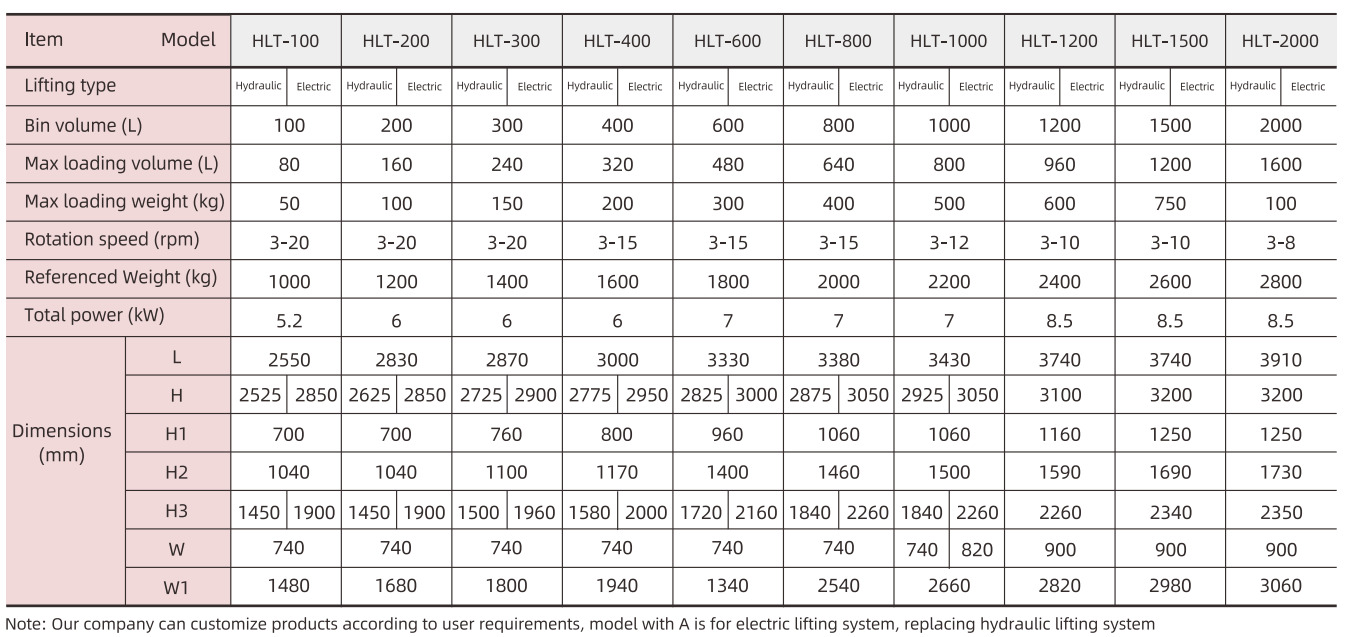

Technical parameter

Note: Our company can customize products according to user requirements.