BGB-F New High-efficiency Coating Machine Optionally Equipped with Tipping Lifting Feeder

- Wonsen

- China

- 120 days

- Strong

▲Overall open design on the front side

▲Easy cleaning, no dead corner

▲Wide install area and maintenance space and pans can be replaceable

▲Unique airbag seal structure, fully enclosed chamber

▲It adopts HM land PLC automatic control system, can optionally comply 21 CFR Part 11 requirements

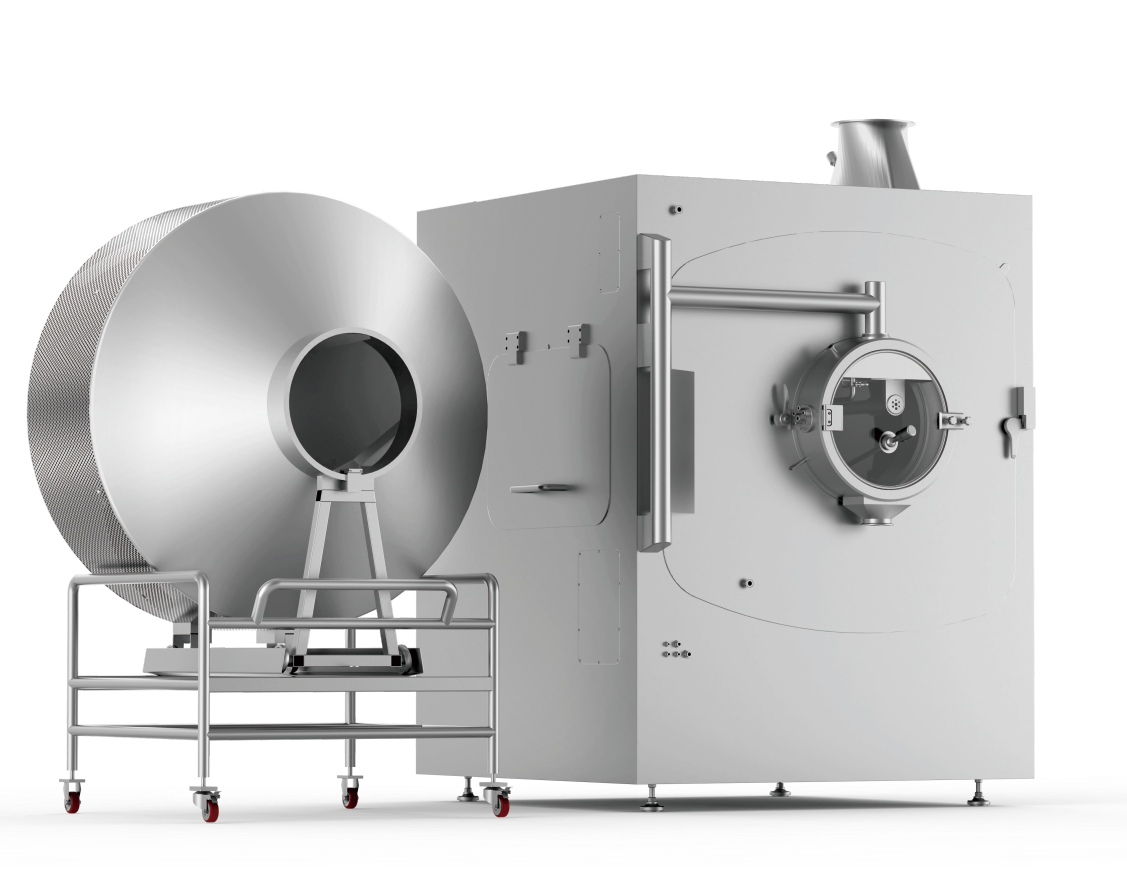

BGB-F New High-efficiency Coating Machine Optionally Equipped with Tipping Lifting Feeder

Introduction

The BGB-F series is a new high-efficiency coating machine designed for aqueous film coating, organic film coating, sustained/controlled-release coating, pill coating, and sugar coating of tablets, pills, candies, and other similar products. It achieves the final coating of core tablets through functions such as tumbling, spraying, and drying. Its manufacturing process, drum interchangeability, and CIP (Cleaning-in-Place) functionality comply with GMP and FDA requirements. While improving auxiliary material utilization and production efficiency, this equipment also ensures product consistency and stability. It is widely used in pharmaceutical, food, and other industries.

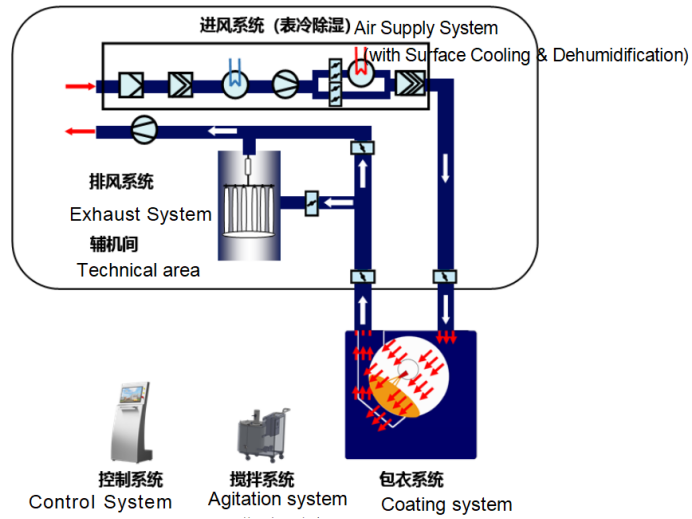

Work principle

Driven by the agitator blades and guide plates inside the rotating drum, the uncoated tablets move along a specific trajectory and mix with the coating solution spray. Meanwhile, filtered and heated air is delivered from the upper right side of the drum by the fan, blows through the material bed, and is discharged from the lower left side of the drum after filtration. This air flow enables rapid and uniform drying of the coating medium sprayed on the surface of the tablet cores, forming a firm and smooth surface film.

Features

1) Front door with open design and unique airbag sealing structure.

2) Patented guide plates, ensuring tablet fluidity while preventing tablet damage.

3) Mesh plate with 50.9% open area, achieving 5% energy saving.

4) Supports interchangeability of coating pans for different production volumes, enabling multi-purpose operation and meeting flexible production needs.

5) Top air supply and bottom air exhaust structure design, increasing coating solution utilization by 5-10%.

6) Supports configuration of an online closed sampling mechanism.

7) Optional tipping lifting feeder available, enabling smooth transfer of tablets into the pan to prevent chipping or breaking caused by impact from height differences, with simple operation.

8) Fully automatic reverse rotation discharging, no tablet crushing, 100% discharging rate, and reduced manual labor intensity.

9) Smooth arc transition between the drum cone and mesh plate, preventing damage to tablets.

10) Added closed-loop control for coating pan rotation speed: detects the actual shaft speed (displayed on the screen), ensuring precise speed unaffected by load or motor speed deviation; also features coupling failure detection and abnormal speed alarm function.

11) Coating solution control can achieve constant pressure and constant flow status.

12) Dust filtration grade F9, meeting national discharge standards with a purification value of less than 20mg/m³ (optional F9+H13 filter for purification value <10mg/m³; optional F9+H14 filter for purification value <1mg/m³).

13) Control system performance (when optional sensors are configured): air volume control accuracy up to ±5%, negative pressure control accuracy up to ±15Pa, and supply air temperature control accuracy up to ±1.5℃.

14) Control system functions (when optional advanced HMI or industrial screen is configured): audit trail, data recording, trend graph, etc.

15) The equipment’s automatic production and automatic cleaning recipes support variable process control; process parameters for each stage can be set independently to meet customers’ customized process requirements.

16) The system is equipped with CIP function, cleaning the air supply hopper, exhaust hopper, drum interior, and drum exterior to achieve zero residue and avoid microbial contamination.

17) Compliant with EU CE certification standards, as well as the requirements of the new version of GMP, CGMP, and FDA regulations.

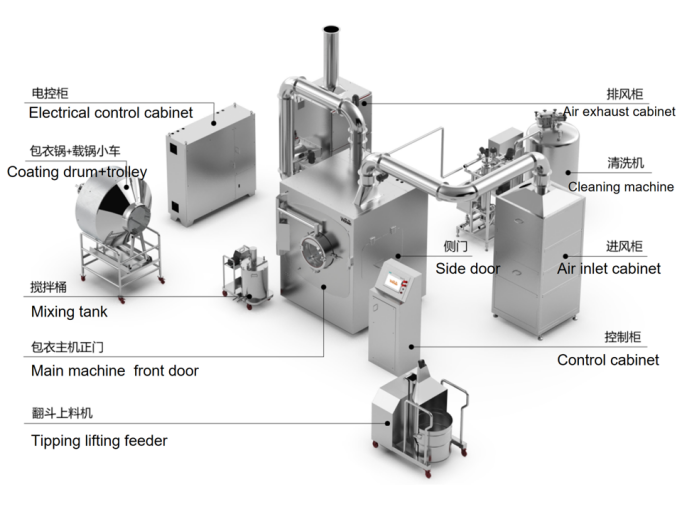

BGB-SL Tipping lifting feeder

BGB-SL tipping lifting feeder can be optionally configured for feeding.

▲Achieving smoothly loading tablet into the coating pan

▲Prevent fragments and bracts because of the height difference colliding

▲Auto lifting and tipping, the tablets can slide into the coating pan evenly and

slowly

Structure

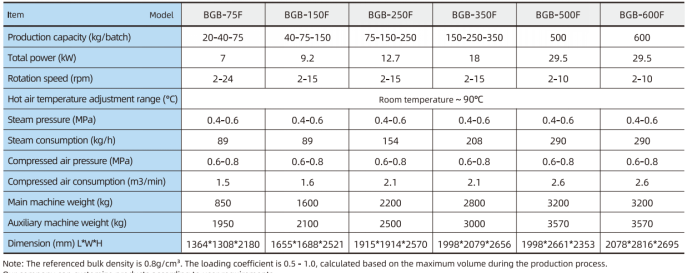

Technical parameter