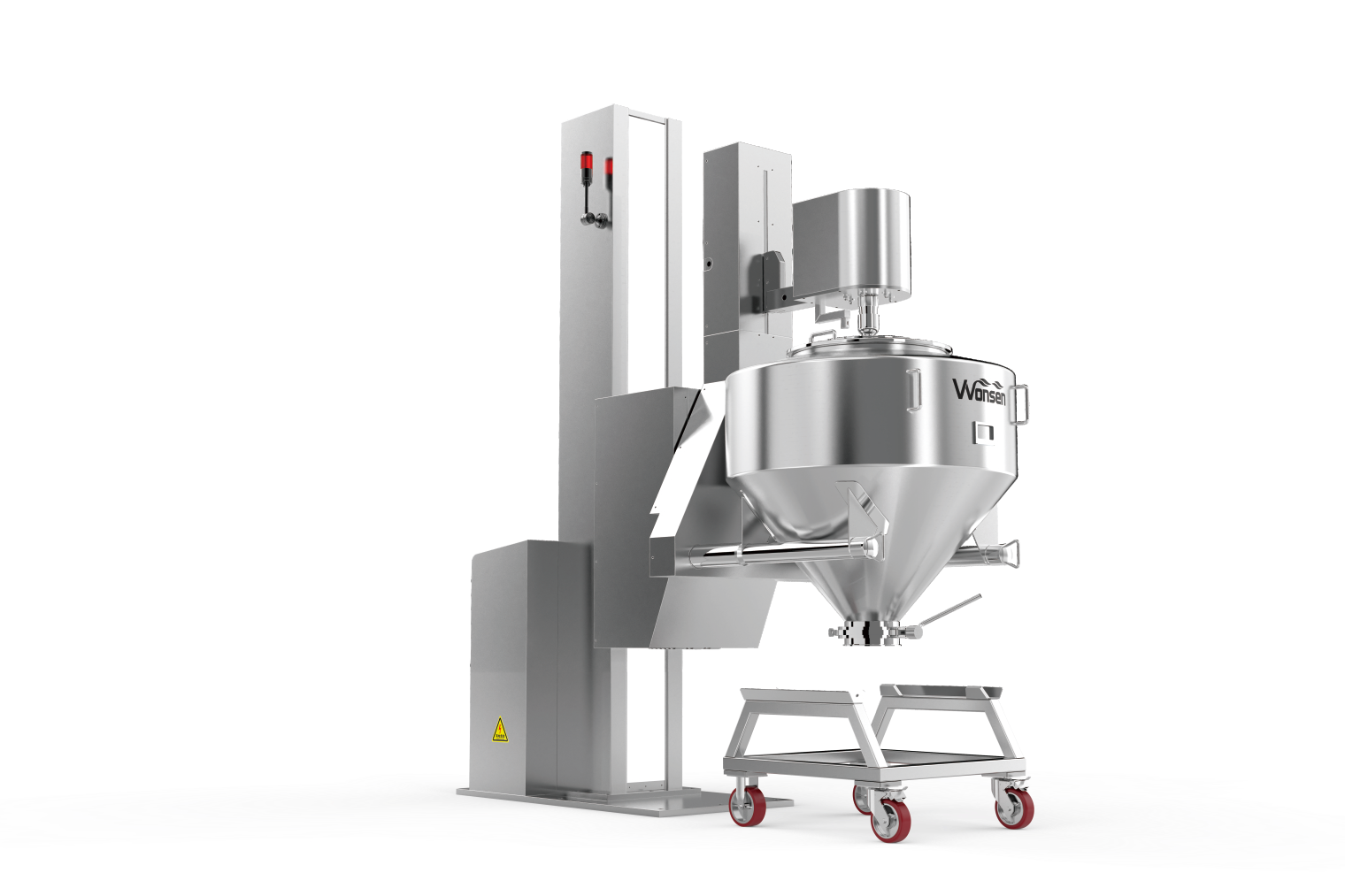

HLT Series Single Column Lifting Bin Blender with Simplified Operation and Easy Parameter Adjustment

- Wonsen

- China

- 120 days

- Strong

▲Single column, saving space, with compact structure, stable and reliable operation

▲With interchangeable mixing bins of different volume for various capacity, improving the efficiency, avoiding cross contamination

▲Can customize round mixing bin, with optional mixing chopper and plates

▲The mixing uniformity is over 99%, the loading coefficient is 0.8 and the bin is easy to clean, no dead corner

▲Meet GMP requirements

▲Adopt HMl and PLC auto control system, can optionally comply 21 CFR Part 11 requirements

HLT Series Single Column Lifting Bin Blender with Simplified Operation and Easy Parameter Adjustment

Introduction

The HLT series single column lifting bin blender is widely used in pharmaceutical production for blending powders, powder-granule mixtures, and granules. Featuring fully automated lifting, mixing, and lowering functions, this high-efficiency system accommodates multiple container sizes for versatile batch processing. Ideal for mid-to-large scale pharmaceutical manufacturers, it supports multi-product, multi-batch operations with single-unit flexibility.

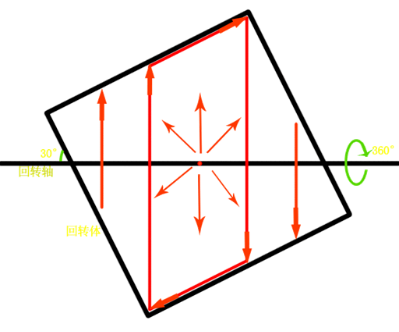

Work principle

The HLT series single-column lifting bin blender performs material mixing by elevating the bin via a vertical column and rotating it around its axis. The offset angle between the bin's symmetrical axis and the rotation arm axis creates intensive three-dimensional movement, generating high shear forces for optimal blending within the closed container.

Workflow

1) Load and secure the bin to the rotation arm by tightening both side nuts;

2) Operators exit the safety perimeter and initiate the control system, setting parameters (mixing time/speed);

3) Initiate operation - bin lifts to mixing height and automatic mixing begins;

4) After mixing, the system returns to horizontal position, lowers the bin and stops;

5) Release the locking nuts and transfer the bin to next process.

Features

1) The blender features hydraulic lifting, motor drive and PLC control for simplified operation and easy parameter adjustment;

2) The mixing bin serves both as a feeding container for previous processes and a discharge hopper for subsequent processes (tableting/filling);

3) Achieves mixing uniformity RSD≤3% with loading coefficient 0.3-0.8. The bin features smooth surfaces (internal/external) with dead-space-free design;

4) The control system is responsive with compact structure and stable operation;

5) Equipped with closed-loop speed control displaying actual shaft speed. Maintains precision regardless of load or motor speed variations, with coupling failure detection and speed anomaly alarm;

6) Compatible with multiple bin sizes. Materials can be transferred directly to next process without discharge, improving efficiency while preventing cross-contamination (GMP compliant);

7) After each batch, empty bins are cleaned in dedicated washing areas to maintain cleanroom conditions.

Structure

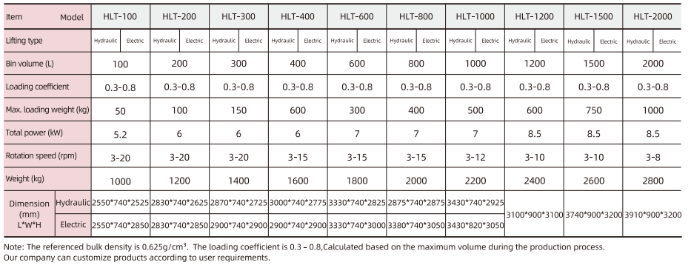

Technical parameter

Note: The referenced bulk densiy is 0.6250/cm3, The loading coeficient is 0.3 - 0.8, calculated based on the maximum volume during the producion proces. Our company can customize products according to user requirements.