Mixer / bin blender

-

Screw Conveyor Connected to Stainless Steel Horizontal Mixer Ribbon Mixer

1. For powder mixing

Email Details

2. Material: Position

3. Bulk density: Approximately 0.5

4. Total volume: 20L

5. Effective volume: 6 - 12L (Batch capacity approximately 6kg)

6. Speed:0~280rpm/min @0~50Hz (controlled by electrical cabinet)

7. Usage environment: Indoor

8. Control system: Siemens 10inch HMI touch screen and PLC, Motor& frequency with Siemens brand

9. Power supply environment: 3PH/220V/50Hz -

Industrial Spices Flour Protein Coffee Powder Mixer Ribbon Blender Dry Powder Mixing Machine

Application:

Email Details

PRB Series Horizontal Ribbon Mixer is a highly efficient and versatile mixing equipment designed for uniformly blending dry powders, granules, and viscous pastes. The unique double-helix ribbon agitator within its U-shaped trough delivers exceptional homogeneity grade in mixing operations.

Engineered by Wonsen, our PRB ribbon blender achieves a maximum mixing ratio of 1:500,000 – meaning it can homogenize trace components as small as 1g within a 500kg batch while maintaining precise formulation requirements. -

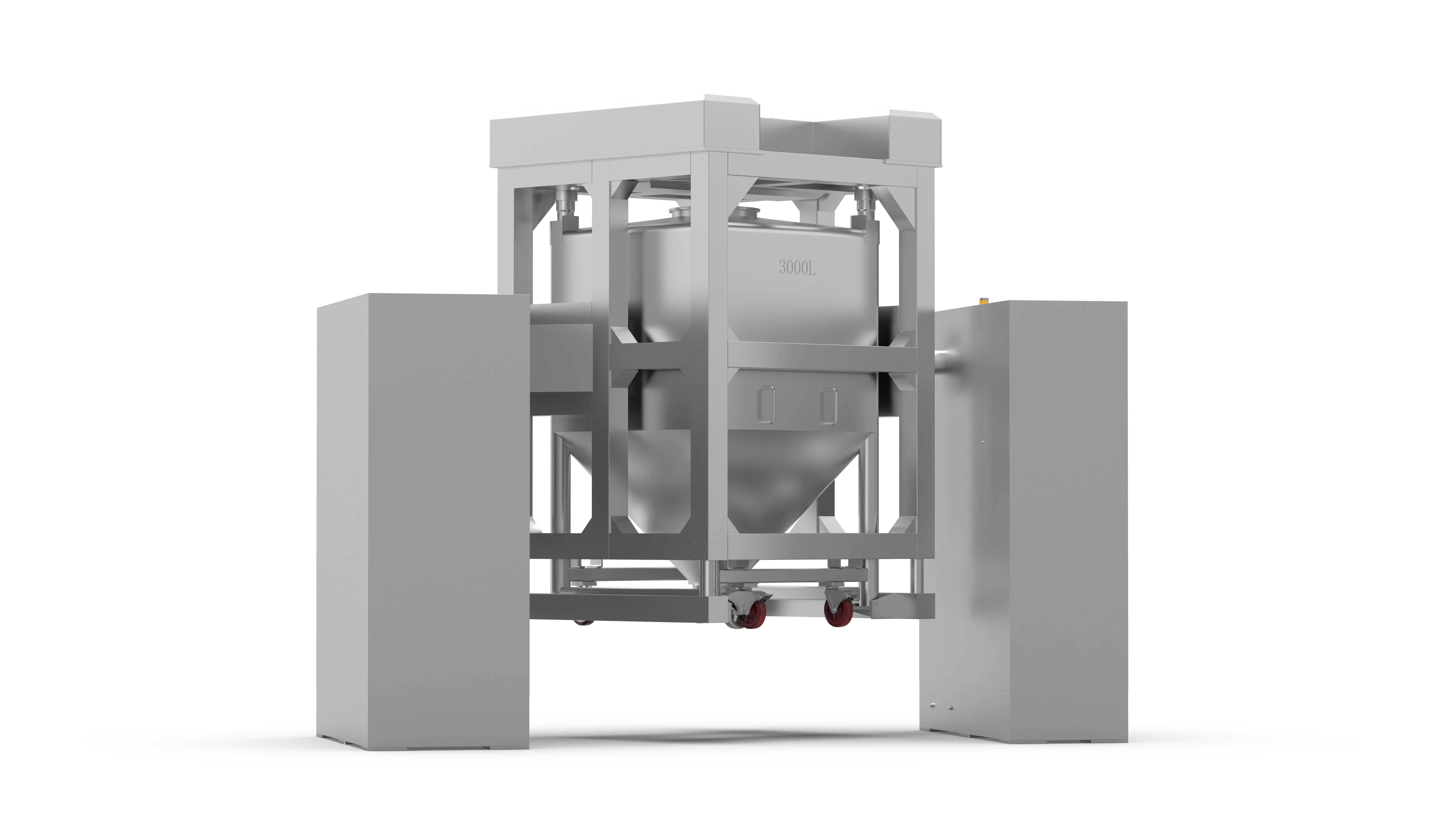

ZTH-3000 360° rotation mixing bin blender lifting machine

1. HMI and PLC control, can display English/Chinese

Email Details

2. 5 level password protection for operation

3. Bin-in-place detection: Automatic positioning of bin after completion of mixing time, vertical with discharging valve at bottom

4. Key Switch (for main On-Off)

5. Mixing speed and time setting

6. RPM and timer display (to be displayed on HMI)

7. Receipe storage (for mixing time, mixing speed, etc)

8. Monitoring of fault and blocking signals;

9. Monitoring the operation of all mixing programs;

10. Archiving keeping data on the progress of the technological process

11. USB data output

12. Equipped with power shutdown protection: Phoenix UPS

13. Complying 21CFR Part11 requirements -

Hot

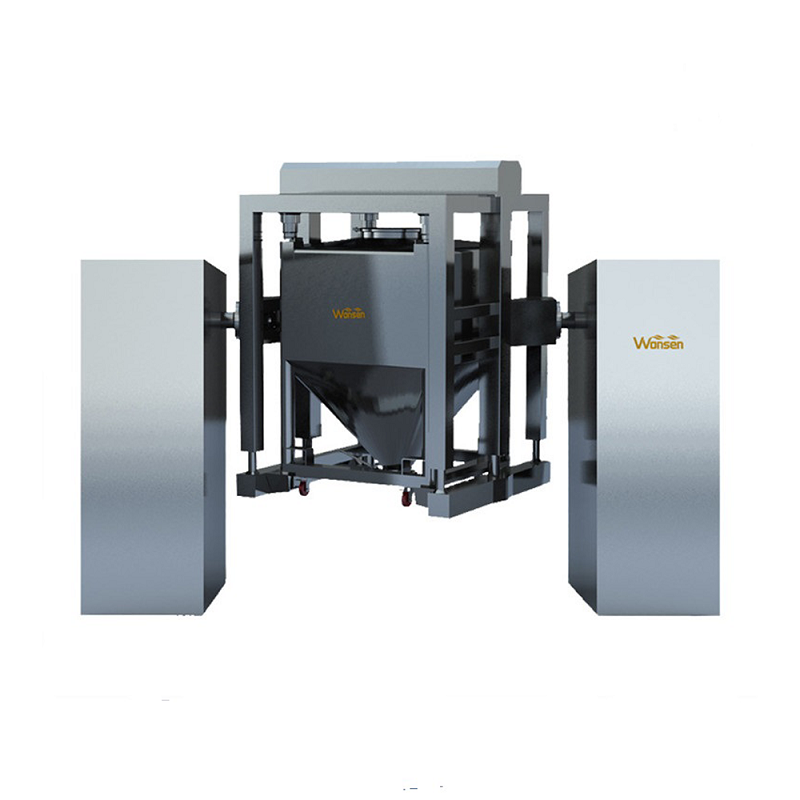

Automatic Lifting Bin Blender

1. Changeable bins design for various capacity

Email Details

2. Human/ machine/ product safety

3. High automation and efficient blending

4. Simple operation and easy to clean -

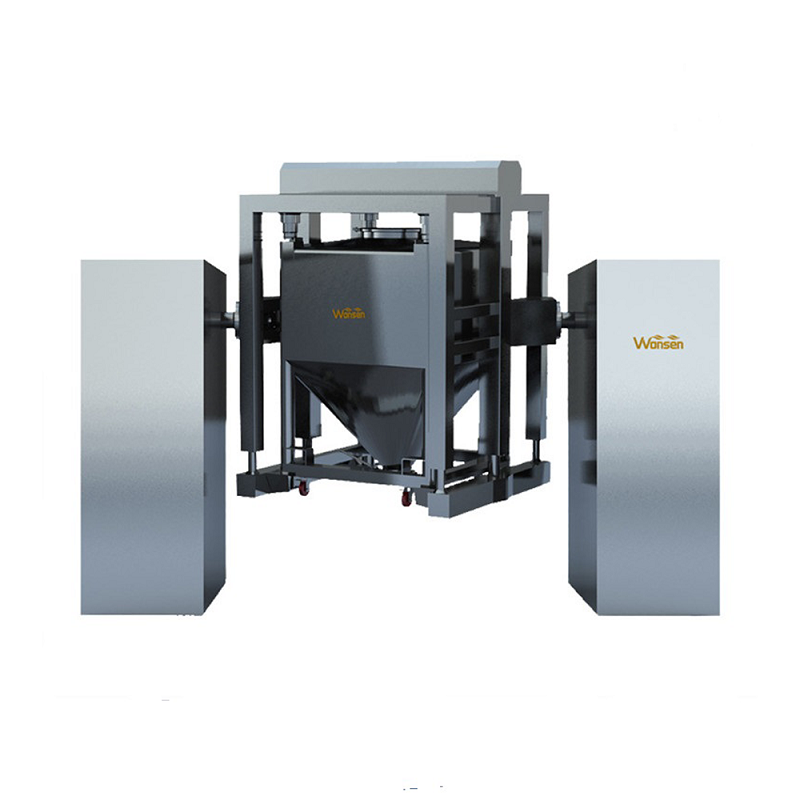

Auto Lifting pharmaceutical Powder bin Blender

1.Changeable bins design for various capacity

Email Details

2. Human / machine / product safety

3 .High automation and efficient blending

4.Simple operation and easy to clean -

New Design Bohle Style Bin Blender With Mixing Chopper

Discharge butterfly valve size (mm): DN200

Material: SUS316L

Capacity: 200kg

Control: PLC+ Touch Screen

mixer type: Paddlebohle style mixing chopper mixing plate interchageable mixing bins mixing motor and reducer 2200w commercial blenderEmail Details -

ZTH-800 Automatic Lifting

The machine is a new machine researched and developed successfully by our company according to China's actual conditions after absorbing and digesting internationally advanced technology.

Email Details

1.The machine has such features as reasonable structure, stable performance, convenient operation, no dead corners, and no exposed bolts.

2.The mixing bin forms an included angle of 30 °with the rotation axis.

The materials in the mixing bin rotate along with the gyrator and make tangential movement along the hopper walls, producing strong turning and high-speed-tangential movement and achieving the best mixing infrared safety device and the discharging butterfly valve with the mis-operation preventer to ensure safe production.

3.The materials can go through different working procedures in the same bin without the need of frequent material transferring, material charging, etc.

4.The machine effectively controls dust pollution and cross contamination, reduces loss of materials, controls material layering, optimizes production processes, and fully meets GMP requirements for medicine production.

5. Good control system sensitivity, compact machine structure and stable and reliable running. -

ZTH-200 IBC bin blender Dry Powder Mixer

1.The machine has such features as reasonable structure, stable performance, convenient operation, no dead corners, and no exposed bolts.

Email Details

2.The mixing bin forms an included angle of 30 °with the rotation axis.

The materials in the mixing bin rotate along with the gyrator and make tangential movement along the hopper walls, producing strong turning and high-speed-tangential movement and achieving the best mixing infrared safety device and the discharging butterfly valve with the mis-operation preventer to ensure safe production.

3.The materials can go through different working procedures in the same bin without the need of frequent material transferring, material charging, etc.

4.The machine effectively controls dust pollution and cross contamination, reduces loss of materials, controls material layering, optimizes production processes, and fully meets GMP requirements for medicine production.

5. Good control system sensitivity, compact machine structure and stable and reliable running. -

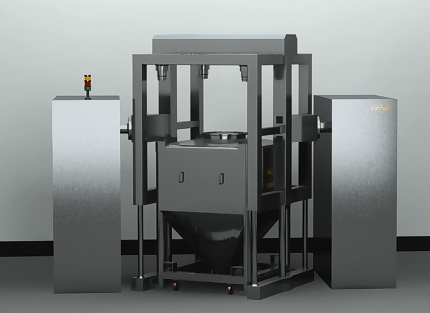

ZTH-1500 360° rotation mixing bin blender lifting machine

1. HMI and PLC control, can display English/Chinese

Email Details

2. 5 level password protection for operation

3. Bin-in-place detection: Automatic positioning of bin after completion of mixing time, vertical with discharging valve at bottom

4. Key Switch (for main On-Off)

5. Mixing speed and time setting

6. RPM and timer display (to be displayed on HMI)

7. Receipe storage (for mixing time, mixing speed, etc)

8. Monitoring of fault and blocking signals;

9. Monitoring the operation of all mixing programs;

10. Archiving keeping data on the progress of the technological process

11. USB data output

12. Equipped with power shutdown protection: Phoenix UPS

13. Complying 21CFR Part11 requirements