Industrial Spices Flour Protein Coffee Powder Mixer Ribbon Blender Dry Powder Mixing Machine

Industrial Spices Flour Protein Coffee Powder Mixer Ribbon Blender Dry Powder Mixing Machine

- Wonsen

- China

- 120 days

- Strong

Application:

PRB Series Horizontal Ribbon Mixer is a highly efficient and versatile mixing equipment designed for uniformly blending dry powders, granules, and viscous pastes. The unique double-helix ribbon agitator within its U-shaped trough delivers exceptional homogeneity grade in mixing operations.

Engineered by Wonsen, our PRB ribbon blender achieves a maximum mixing ratio of 1:500,000 – meaning it can homogenize trace components as small as 1g within a 500kg batch while maintaining precise formulation requirements.

Products Description

Features

Features

- For powder mixing

- Material: Position

- Bulk density: Approximately 0.5

- Total volume: 20L

- Effective volume: 6-12L (Batch capacity approximately 6kg)

- Speed:0~280rpm/min @0~50Hz(controlled by electrical cabinet

- Usage environment: Indoor

- Control system: Siemens 10inch HMI touch screen and PLC, Motor& frequency with Siemens brand

- Power supply environment: 3PH/220V/50Hz

- Material: Position

- Bulk density: Approximately 0.5

- Total volume: 20L

- Effective volume: 6-12L (Batch capacity approximately 6kg)

- Speed:0~280rpm/min @0~50Hz(controlled by electrical cabinet

- Usage environment: Indoor

- Control system: Siemens 10inch HMI touch screen and PLC, Motor& frequency with Siemens brand

- Power supply environment: 3PH/220V/50Hz

Application

Application

PRB Series Horizontal Ribbon Mixer is a highly efficient and versatile mixing equipment designed for uniformly blending dry powders, granules, and viscous pastes. The unique double-helix ribbon agitator within its U-shaped trough delivers exceptional homogeneity grade in mixing operations.

Engineered by Wonsen, our PRB ribbon blender achieves a maximum mixing ratio of 1:500,000 – meaning it can homogenize trace components as small as 1g within a 500kg batch while maintaining precise formulation requirements.

Working principle

The Wonsen PRB Ribbon Mixer comprises a drive unit, U-shaped trough, and dual counter-rotating ribbon agitators

(inner and outer helices). During operation:

Material Convection Flow

- The outer ribbon pushes material from both ends toward the center of the trough.

- The inner ribbon drives material from the center toward both ends.

- Creates intense counter-current convective flow.

3D Homogenization

- Material ascends along the ribbon edges and descends under gravity.

- Generates a three-dimensional flow field throughout the trough.

- Enables rapid blending with short mixing cycles and low power consumption.

Discharge Mechanism

- Post-mixing, material discharges via a flush-mounted discharge gate valve at the trough bottom.

- Valve operation: Pneumatic or manual.

- Adjustable discharge height enables dust-free transfer to downstream containers.

Sealing & Loading

- Main shaft sealing: Multi-layer PTFE packing in stuffing boxes at both ends (optional lantern ring for air purge).

- Loading: Top-fed via open trough or inlet ports.

- Drain: Central flush-bottom valve with cleaning connection.Generates a three-dimensional flow field throughout the trough.

- Enables rapid blending with short mixing cycles and low power consumption.

Discharge Mechanism

- Post-mixing, material discharges via a flush-mounted discharge gate valve at the trough bottom.

- Valve operation: Pneumatic or manual.

- Adjustable discharge height enables dust-free transfer to downstream containers.

Sealing & Loading

- Main shaft sealing: Multi-layer PTFE packing in stuffing boxes at both ends (optional lantern ring for air purge).

- Loading: Top-fed via open trough or inlet ports.

- Drain: Central flush-bottom valve with cleaning connection.

Certifications

Our Advantages

Why Choose Us

Manufacturing Technique

Exhibition

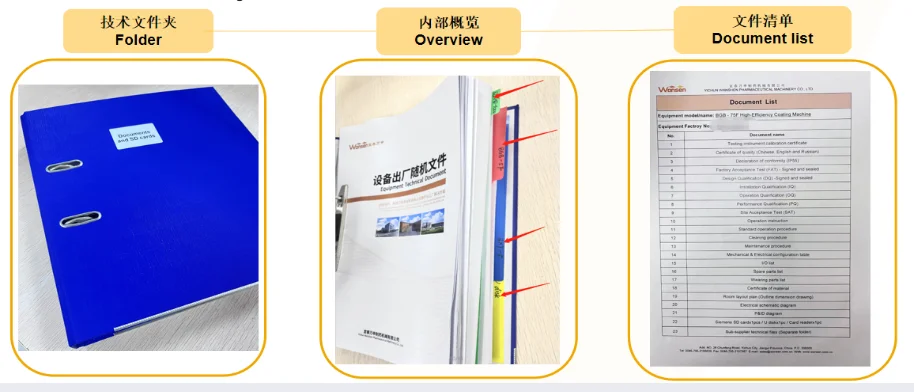

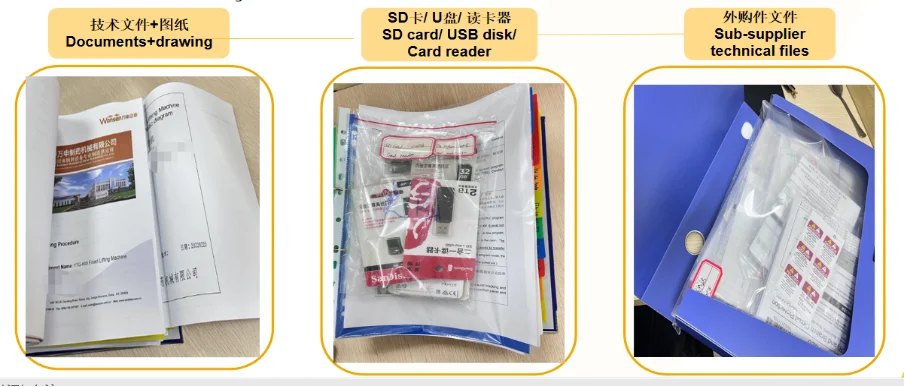

Technical Document