FL Fluid Bed Granulator with ATEX-certified Centrifugal Blower Fully Meet FDA

- Wonsen

- China

- 120 days

- Strong

▲With top spraying for granulation

▲Two heating modes alternative, such as electric heating or steam heating

▲PID precision control

▲High processing efficiency, with closed online sampling

▲Ex-proof system/anti-10 or 12 bar/final dedusting system/dehumidifier system are available

▲WIP system/PAT are available

▲Fully meet FDA, CGMP, GMP

▲Control system can optionally complying 21CFR Part11 requirements

FL Fluid Bed Granulator with ATEX-certified Centrifugal Blower Fully Meet FDA

Introduction

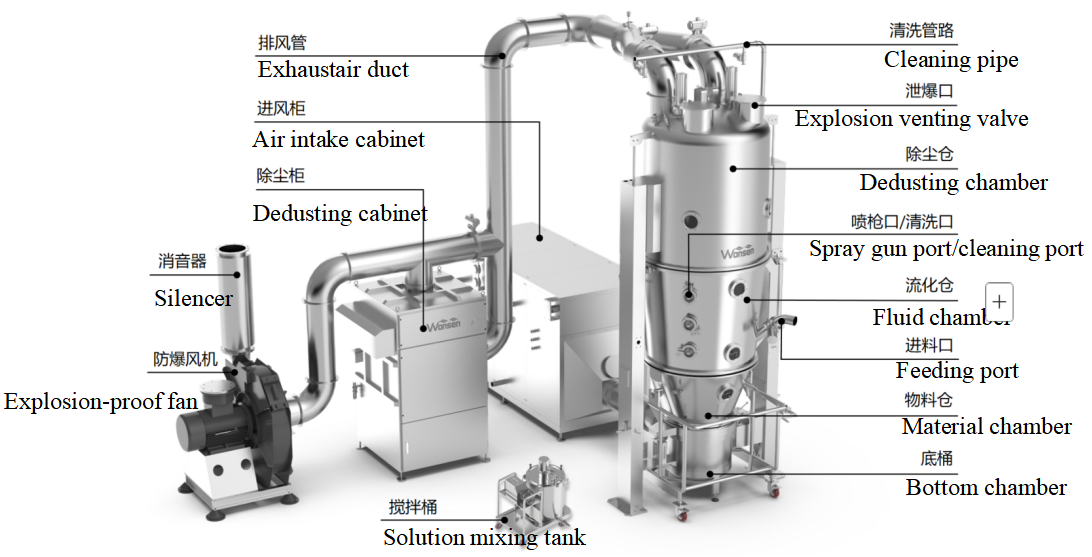

The FL fluid bed granulator is a pharmaceutical-grade equipment integrating mixing, granulation and drying functions in a GMP-compliant, dead-space-free design with polished surfaces, operating under negative pressure for containment. It serves pharmaceutical (including TCM), food and chemical applications.

Work principle

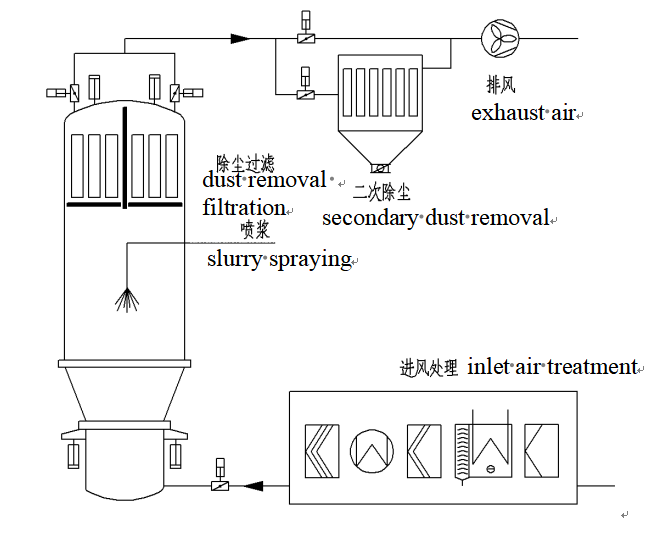

The fluid bed granulator consists of a main unit, spraying module, air inlet module, exhaust module, and control module. Material is loaded into the product container. Process air undergoes primary filtration, medium filtration, dehumidification (Option), heating, and HEPA filtration in the air inlet module before entering the main unit.The conditioned air passes through an air distribution plate to achieve uniform velocity for material fluidization. Binder liquid is delivered via a peristaltic pump to spray nozzles, atomized, and continuously coated onto fluidized particles to promote agglomeration. Simultaneous drying with heated air forms granules.

During granulation, fine powder entrained in the airflow is filtered by dust bags in the dust removal module and discharged through the exhaust module. Post-granulation, discharge is achievable via manual operation, lifting-tilting granulator, or vacuum discharge through a closed connection with a lifting vacuum granulator.

Features

1)Utilizing PID control with Siemens proportional valves, the air temperature is adjustable from ambient to 120°C. With stable steam supply and proper steam traps, temperature stability is maintained within ±2°C of setpoint to prevent fluctuations and enhance production stability.

2)The system achieves 11 g/kg inlet humidity via coil dehumidification. Optional desiccant wheel reduces humidity to 5–8 g/kg, with an oversized wheel option achieving 3–4 g/kg and dual-wheel systems maintain humidity ≤1 g/kg

3)Air handling system: Standard G4 pre-filter + F8 medium filter + H13 HEPA (with DOP test port for integrity testing).

4)Differential pressure gauges on primary/intermediate filters monitor clogging; HEPA differential pressure analog signal displays on HMI.

5)Proportional valve controls negative pressure to prevent bed collapse.

6)Tapered expansion chamber with multi-height spray nozzles.

7)Optimized distribution plate ensures uniform airflow and granule size distribution.

8)Upgraded PTD-3D antistatic filter bags: Non-stick, high permeability, cleanable.

9)Top-mounted directional explosion vent protects pressure-sensitive components.

10)Secondary dust filtration: F9 (<20 mg/m³). Options: F9+H13: <10 mg/m³, F9+H14:<1 mg/m³

11)ATEX-certified centrifugal blower maintains stable airflow/pressure

12)Optional CIP system cleans Bottom chamber, product container, fluidized chamber, and filter housing.

13)Recipe-driven automation for production/cleaning cycles with customizable parameters.

14)Five-tier password control: Monitor/Operator/Technician/Maintenance/Admin.

15)Airflow control accuracy: ±5%; Supports audit trail, data logging, and printing.

16)Moisture-based endpoint detection for granulation.

17)CE compliant (EU Machinery Directive 2006/42/EC).

Structure

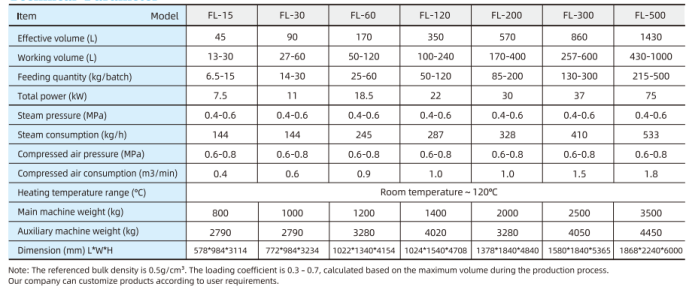

Technical parameter