fl

-

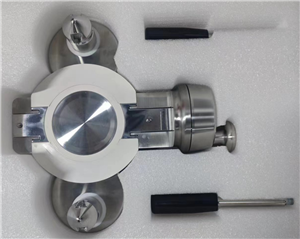

Stainless Steel α Special Split Butterfly Valve Pneumatic Active Valve

The active valve bodies feature a symmetrical design, eliminating the risk of scraping or debris generation during docking and opening, thereby reducing material contamination.

Email Details -

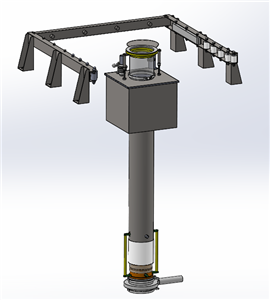

HZTD-1200 Maximum Working Volume 960L with Manual Discharge Butterfly Valve

Inner surface: mirror polished to Ra ≤ 0.2 μm; Outer surface: brushed finish to Ra ≤ 0.4 μm

Email Details -

DPL-200 Top Spray for Granulation and Drying Functions Bottom Spray For Coating Functions

The automatic production and automatic cleaning formulas of the equipment support variable process control, and the process parameters of each stage can be set independently to meet the needs of customers' customized processes

Email Details -

DPL-300 All-in-One Fluid-Bed Processor:Top-Spray Granulation, Bottom-Spray Coating, Instant Drying

The equipment adopts PLC full-automatic control. All operations can be automatically completed by setting process parameters according to user requirements. It can print all process parameters, with true and reliable original records, fully complying with GMP requirements for pharmaceutical production.

Email Details -

Mobile Granulator Used for Sizing Wet-granulated or Spray-granulated Agglomerates

Adopting modular design, dry and wet granulation can be achieved by replacing the whole grain knife and sieve. A quantitative feeding mechanism can be configured to improve particle size consistency, and a closed silo can be configured to reduce dust leakage

Email Details -

Spray dryer for drying liquid to powder

Product Features: 1. Adopt rotary cutting air inlet technology and adjustable volute to ensure uniform distribution of materials and no reverse top. 2. The heat source can be electric heating, steam heating or a combination of various heating methods to ensure high efficiency and low consumption. 3. The whole machine is compact and beautiful in structure, easy to operate, the hot air chamber can be disassembled and cleaned, and the inlet air temperature can be adjusted and controlled. 4. Air jacket cooling system is adopted for the drying chamber and top parts to prevent the material from being melted and hung on the chamber 5. The inner wall of the drying chamber adopts an air rotary blowing device to eliminate or reduce the sticking phenomenon. 6. The powder collecting system adopts dehumidification air blowing cooling technology to cool the product and prevent moisture absorption and agglomeration. 7.It with GMP production requirements, dry air cleanliness is better than 100,000 grades, easy to clean, and product quality is stable.

Email Details -

CL Inter-floor Material Dropping Device Automatic Connection Device

Multi-layer Dropping Component: The outer layer is made of stainless steel pipe, which facilitates the installation of the equipment. The middle layer is a silicone pipe that ensures elasticity. The innermost layer is a PE straight-through bag that allows for quick replacement and easy cleaning of the equipment.

Inter-floor Material Dropping Device Interlayer Scrap Cutting Device Automatic Connection Device Multi-layer Dropping ComponentEmail Details -

New Model Multifunctional Fluid Bed Granulator Integrates Top-Spray Granulation and Bottom-Spray Coating Functions

(1)The control system is equipped with five-level password authorization, which is authorized and managed for monitors, operators, process personnel, maintenance personnel and managers respectively; (2)Meeting the EU CE standards.

Top-Spray Granulation Multifunctional Fluid Bed Granulator Fluid Bed Granulator Bottom-Spray CoatingEmail Details -

GY series Pressured Binder Tank Used in Mixer Granulator and Other Equipment

(1)The lower part of the tank is equipped with a quick-clamp manual ball valve to control the liquid discharge. (2)The liquid outlet is equipped with a supply pipe of a certain length.

Email Details