GY series Pressured Binder Tank Used in Mixer Granulator and Other Equipment

- Wonsen

- China

- 120 days

- Strong

(1)The lower part of the tank is equipped with a quick-clamp manual ball valve to control the liquid discharge.

(2)The liquid outlet is equipped with a supply pipe of a certain length.

GY series Pressured Binder Tank Used in Mixer Granulator and Other Equipment

Introduction

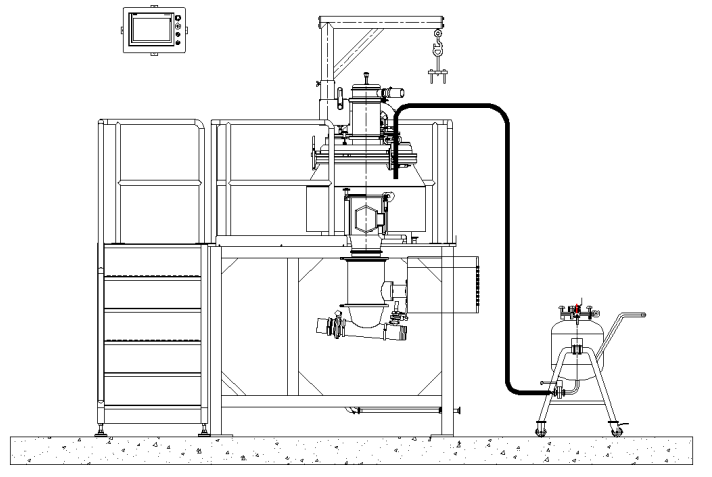

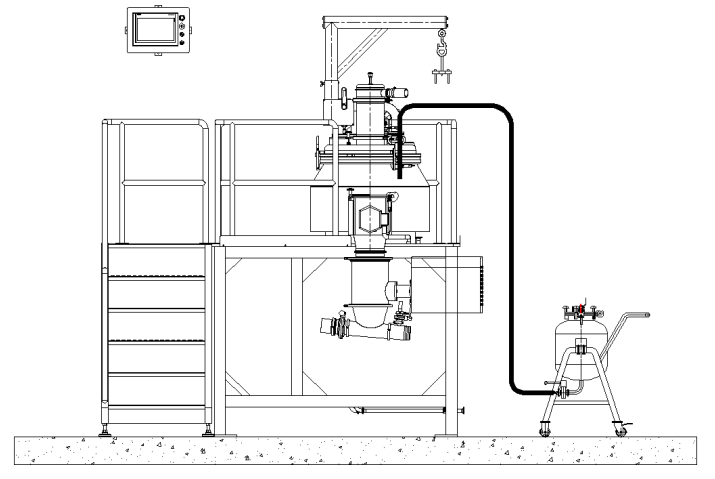

The GY series Pressured Binder Tank is mainly used in Mixer Granulator and other equipment. It is used in conjunction with a spray gun to automatically add slurry to the material in the pot, effectively preventing the unevenness caused by manual slurry addition, reducing labor intensity, and improving work efficiency. Made of high-quality stainless steel, the parts in contact with the material are polished to a mirror finish, effectively reducing cross-contamination and providing assurance for the pharmaceutical industry to successfully pass the "GMP" certification.

Work principle

The air inlet at the top of the Pressured Binder Tank is connected to compressed air, and the liquid outlet at the bottom is connected to the equipment spray gun via a transparent hose. When both the air inlet valve and the material outlet valve of the tank are opened, the slurry is conveyed to the spray gun of the Mixer Granulator under the pressure of the compressed air through the transparent hose, completing the slurry addition process. The speed of slurry conveyance can be adjusted by regulating the pressure of the compressed air through the pressure regulator at the air inlet.

v

v

Features

1) The top of the grouting tank is equipped with a lid and a handwheel locking device.

2) Connect the system to the power supply.

3) The upper part of the tank is equipped with a compressed air inlet, which includes a safety valve and a pressure regulating valve.

4) The lower part of the tank is equipped with a quick-clamp manual ball valve to control the liquid discharge.

5) The grouting cart is equipped with four swivel casters (with brakes) for easy movement.

6) The liquid outlet is equipped with a supply pipe of a certain length.

7) The inner surface of the tank is polished to a mirror finish, while the outer surface is treated with hairline or sandblasting.

Technical parameter

For specific technical parameters, please leave a message for inquiry.