CL Inter-floor Material Dropping Device Automatic Connection Device

- Wonsen

- China

- 120 days

- Strong

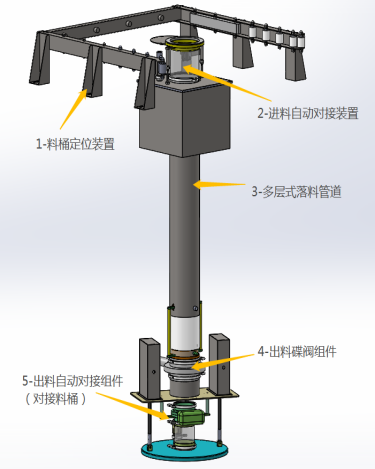

Multi-layer Dropping Component: The outer layer is made of stainless steel pipe, which facilitates the installation of the equipment. The middle layer is a silicone pipe that ensures elasticity. The innermost layer is a PE straight-through bag that allows for quick replacement and easy cleaning of the equipment.

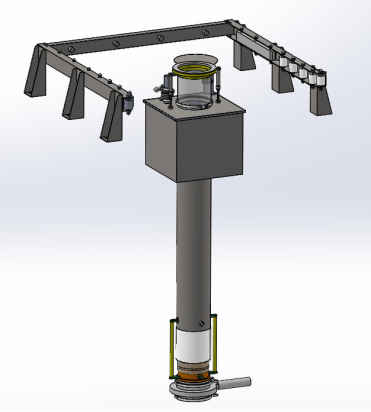

CL Inter-floor Material Dropping Device Automatic Connection Device

Introduction

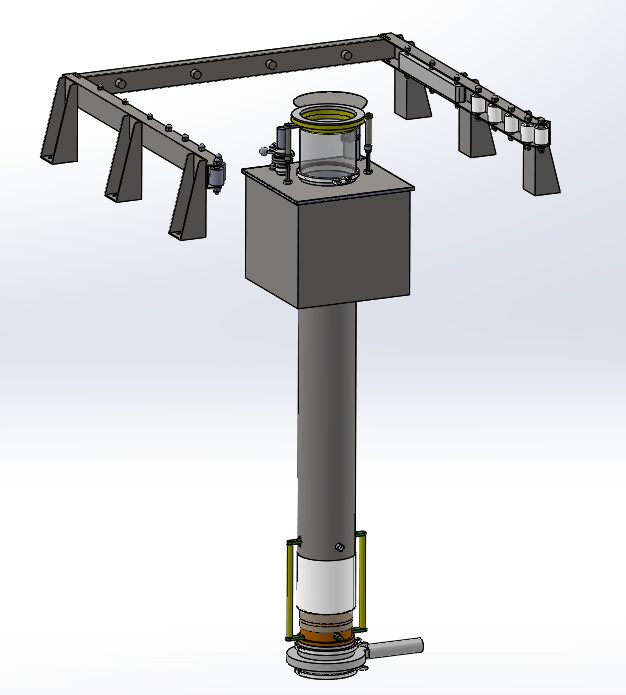

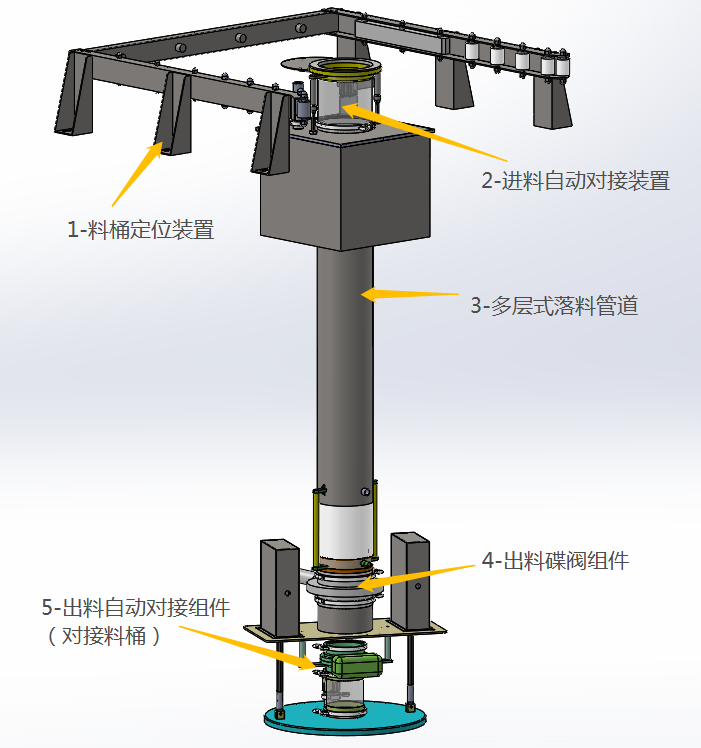

The CL Inter-floor Material Dropping Device is suitable for the gravity conveying of powders, granules, and tablets in the pharmaceutical, food, and chemical industries. Both the inlet and outlet can achieve automatic connection. The principle is to reduce the falling speed of the material by inflating and squeezing the elastic hose to change the diameter of the tube, thereby preventing material stratification (which affects the degree of mixing), the collision and breakage of granules and tablets, and the bridging of the material. It also effectively reduces the falling speed and reduces damage to the downstream equipment.

The device uses PLC automatic control, allowing for interlocked control between the upper and lower floors. The materials used are all food-grade and fully comply with the GMP requirements for pharmaceutical production.

Work principle

The device consists of an inlet docking assembly, a material dropping pipeline assembly, an outlet docking assembly, and a control system assembly. In terms of operation and control, both automatic and manual control modes are provided.

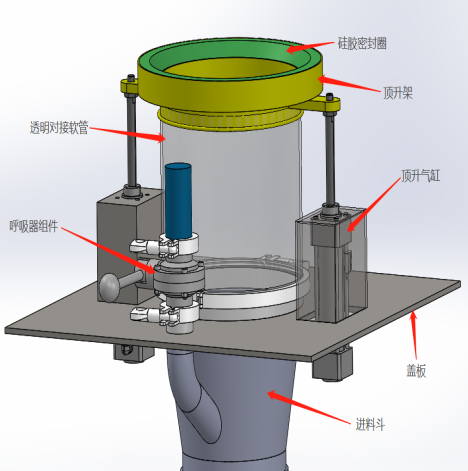

During operation, the operator manually pushes the material drum into the working position and secures it. Then, by pressing the “Start Dropping” button on the control cabinet of the dropping pipeline, the automatic docking is initiated. The inflation and pressure-holding program starts automatically, and the drum’s butterfly valve is opened (if the drum is equipped with a manual butterfly valve, it needs to be opened manually) to start feeding the material. At the upper end (feeding end), once the upper material level sensor is activated, the exhaust action is automatically initiated. This ensures the material falls slowly. When the material reaches the lower end (discharge end) and the lower material level sensor is activated, the discharge butterfly valve opens automatically, completing the material dropping process.

Throughout the entire material conveying and feeding process, the PLC can determine whether the process is normal or abnormal based on the activation status and sequence of the upper and lower material level sensors.

Features

Automation Control System:

1. The control system utilizes a PLC (Programmable Logic Controller) to enable one-button operation for the entire control process.

2. Control terminals are installed at both the discharge end and the feed end of the pipeline, facilitating interlinked functionality between the two ends.

3. The upper and lower material level sensors are designed to cross-validate each other's actions, directly determining whether the conveying status is normal or abnormal and identifying the cause.

4. The inflation and pressure-holding device is equipped with imported pressure sensors from abroad.

5. In the event of abnormal operation, the system can trigger audio and visual alarms.

6. The material dropping speed is adjustable.

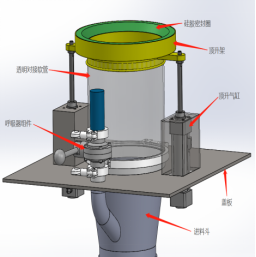

Docking System:

1. The system employs a pneumatic cylinder lift mechanism, which provides strong clamping force. The docking port is made of soft, food-grade material, effectively preventing powder leakage.

2. An automatic rotating cover is added to prevent material contamination.

3. The inlet is equipped with a breather, which can supply air to the pipeline, ensuring smooth material dropping.

4. The system extensively uses quick-connect PU flexible connections, which offer good sealing performance, high flexibility, and high transparency.

5. The upstream and downstream equipment can be diverse, with mixers, material drums, packaging machines, and reactors all capable of automatic docking with the pipeline.

Multi-layer Dropping Component:

The outer layer is made of stainless steel pipe, which facilitates the installation of the equipment. The middle layer is a silicone pipe that ensures elasticity. The innermost layer is a PE straight-through bag that allows for quick replacement and easy cleaning of the equipment.