ZTP-200/ZTP-300 Rotary Tablet Press Machine with Reliable and Stable Detection Performance

- Wonsen

- China

- 120 days

- Strong

(1)Automatic safety protection and alarm function, including overload protection for punch and die sets, main motor failure protection, and other multiple safety protection.

(2)Compliance with 21 CFR PART 11, featuring electronic signature and electronic record functions.

ZTP-200/ZTP-300 Rotary Tablet Press Machine with Reliable and Stable Detection Performance

Introduction

The rotary tablet press machine is a piece of equipment that feeds various granule or powder materials from the material hopper into the forced-feeding chamber, where the paddle feeder fills them into the die cavities. The multiple punch and die sets, evenly distributed on the turret, move in a circular up-and-down motion along a predefined trajectory, to compact the material into tablets.

Features

1) Automated control of pre-compaction, main compaction, and filling dosing to enhance consistency.

2) Imported detection system for precise adjustment of filling depth and tablet thickness.

3) Imported pressure sensing system with reliable and stable detection performance.

4) Automatic safety protection and alarm function, including overload protection for punch and die sets, main motor failure protection, and other multiple safety protection.

5) Compliance with 21 CFR PART 11, featuring electronic signature and electronic record functions.

6) Conforms to the requirements of US FDA and EU GMP regulations.

Structure

The rotary tablet press machine mainly consists of the main frame, pre-compaction and main compaction roller modules, feeder, turret module, material dosing device, tablet ejection channel, dedusting system, data acquisition system, and electrical control system.

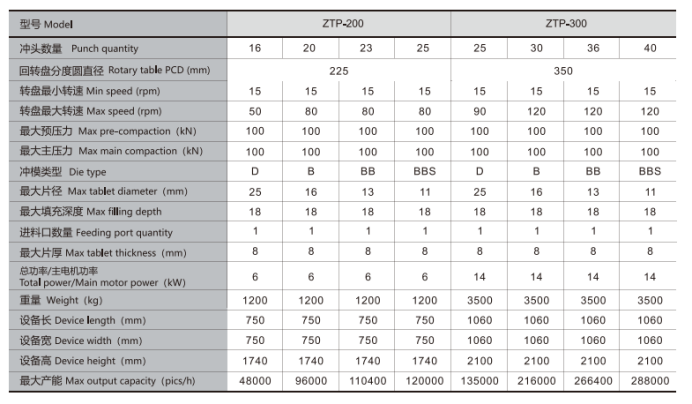

Technical parameter