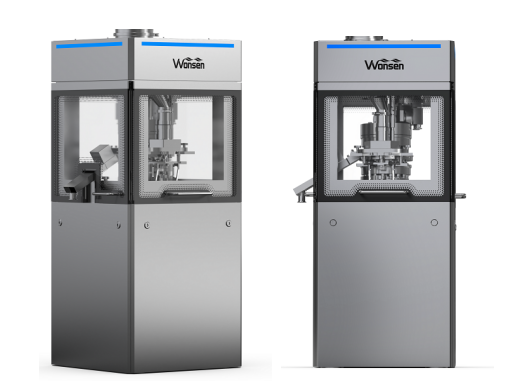

ZTP-200 High Speed Rotary Tablet Press Machine with fully Automatic Thin Oil Lubrication System

- Wonsen

- China

- 120 days

- Strong

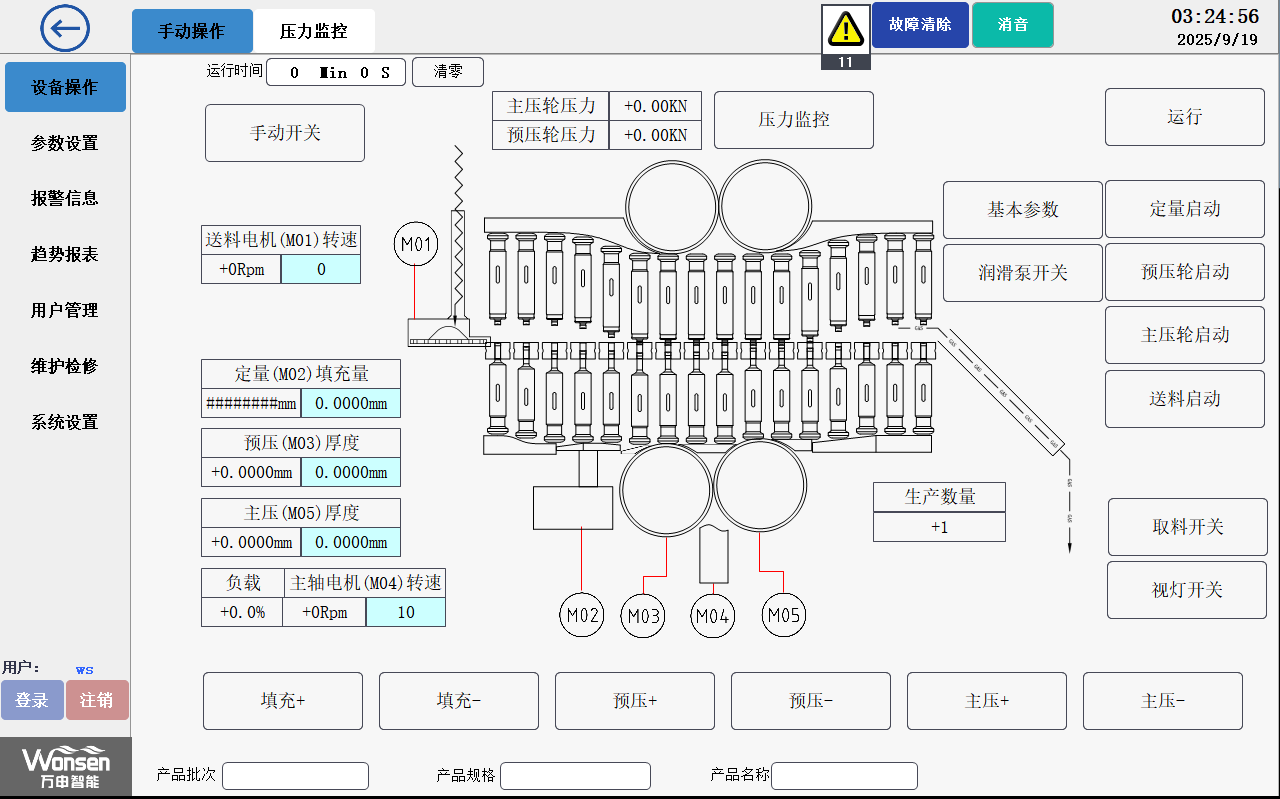

● Show and control punch qunantity/pressure/thickness/filling depth/motor speed on HMI

● Automatic adjustment of tablet weight

● Defective tablet rejection in batches

● Fully automatic thin oil lubrication system

● Over load protection system

● Metering servo drive system

● Automatic recording of process data during production

ZTP-200 High Speed Rotary Tablet Press Machine with fully Automatic Thin Oil Lubrication System

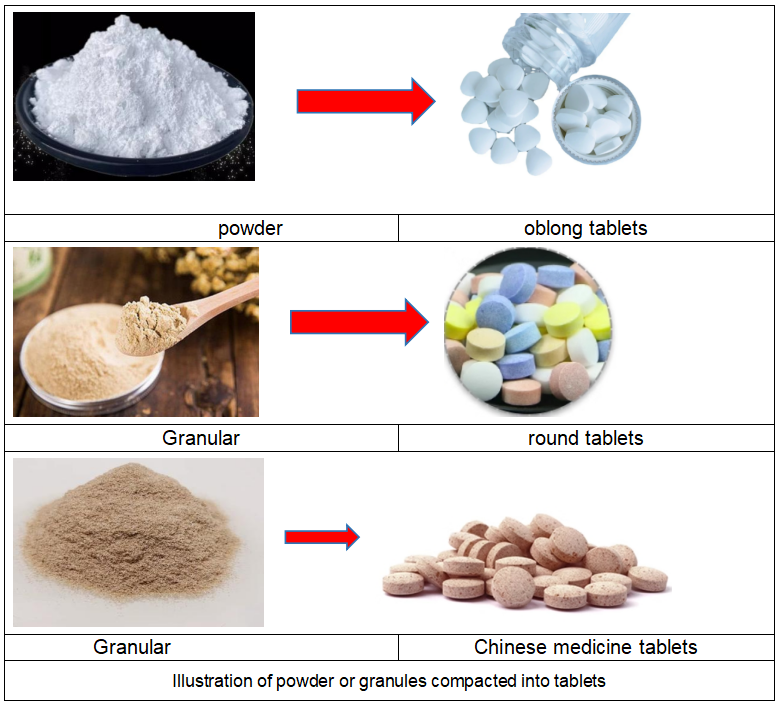

Introduction

ZTP-200 High Speed Rotary Tablet Press Machine converts granules or powders into tablets. It can be used for the production of single-layer tablets, double-layer tablets, ring-shaped tablets, round tablets, and irregularly shaped tablets.

ZTP-200 High Speed Rotary Tablet Press Machine features high precision, high speed, and high automation, making it the ideal equipment for large-scale tablet production.

It complies with GMP standards:

Ø Tablet weight difference: ±3% (for tablets > 0.3g); ±4% (for tablets ≤ 0.3g); Average difference: ≤ ±2% (The tablet weight precision of the tablet press also depends on various factors, such as the pressure of the material, tablet specifications, and the precision of the molds.)

Ø Yield rate is over 99% (The yield rate also depends on factors such as the condition of the powder and the molds.)

Ø Metal parts that come into direct contact with the material are made of 316L material, which is smooth and flat.

Ø Metal parts that do not come into direct contact with the material are made of SUS304 material.

Ø Automatic adjustment of tablet weight.

Ø Automatic rejection of defective tablets based on position algorithm.

Ø Real-time online monitoring of pre-pressure and main pressure forces.

Ø Maximum pre-pressure and main pressure forces are both 100 kN.

Ø Large-diameter main pre-pressure wheels that can be interchanged, which helps to expel air and extend the pressure time.

Ø A new pressure detection structure has been developed to solve the problem of pressure drift, making pressure detection more accurate.

Ø Advanced modular design for easy operation and maintenance.

Ø Rigid support for the press wheels to ensure the best tablet forming effect and thickness consistency.

Ø Servo motor (option), worm gear, and high-precision screw to adjust the position of the press wheels with high precision.

Ø Servo motor system, worm gear, and high-precision lead screw to adjust the filling depth. A pressure spring is also equipped in the dosing module to eliminate clearance and ensure tablet weight precision.

Ø Special oil-proof, dust-proof, and noise-reducing systems.

Ø The punch and die process is synchronized with international standards, offering an extra-long service life.

Ø Double-layer three-paddle filling system to balance the density of the powder and ensure uniform filling.

Ø Double-layer cover design to reduce the risk of cross-contamination.

Ø The tablet press chamber can be fully opened 360° without dead angles, making it easy to clean and maintain.

Ø Ample space for guide rails and punch and die disassembly and assembly, facilitating maintenance and upkeep.

Ø Four-column frame structure, stable and durable.

Ø Fully automatic thin oil lubrication system.

Ø High-definition isolation sight window design.

Ø New drive technology with low-speed high torque for continuous and stable operation.

Ø Complete set of advanced Siemens control systems.

Ø 12-inch Siemens touch screen, no handwheel operation, highly automated production.

Ø 15-inch industrial panel PC (option).

Ø A brand-new UI design, with a more user-friendly interface and more convenient operation.

Ø All production information can be displayed, stored, retrieved, and modified.

Ø User password protection.

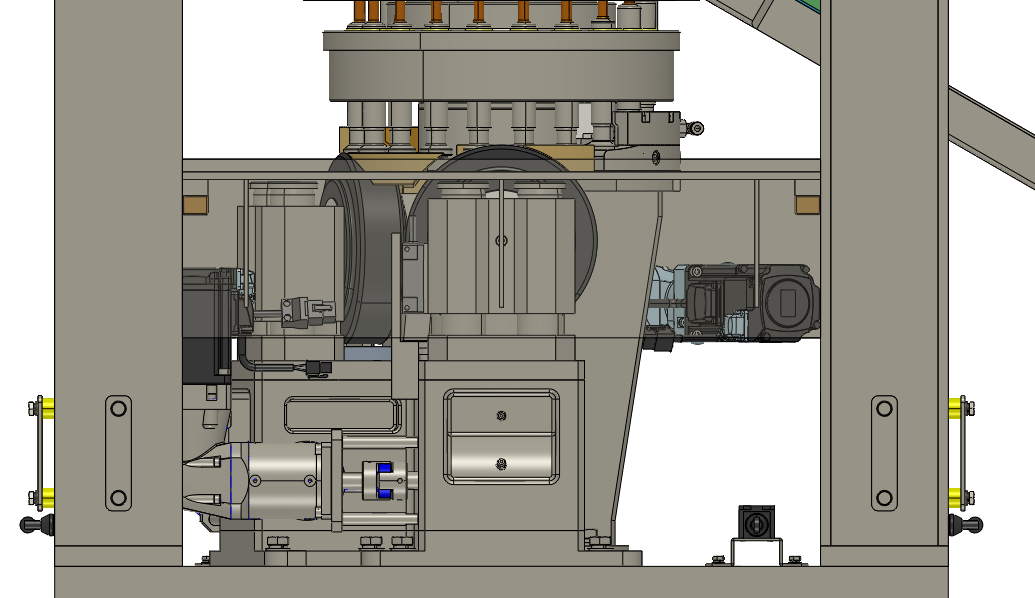

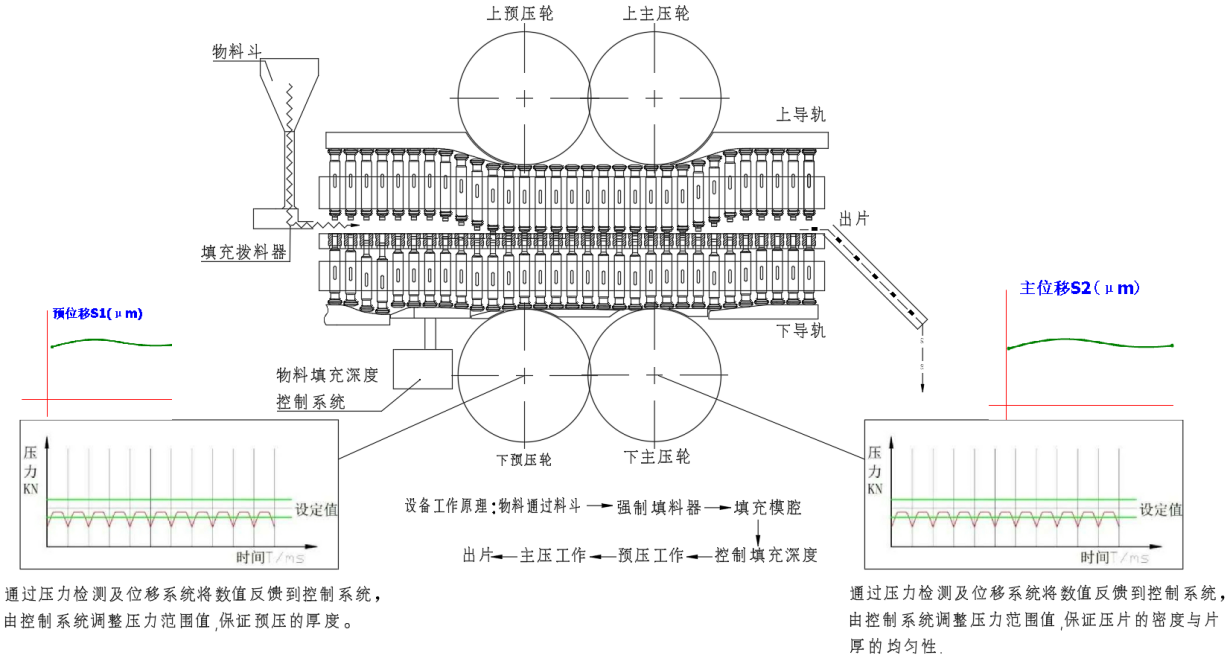

Tablet pressure process

The following is an unfolded diagram of the punch and die and the track. The tablet pressure process is introduced from left to right according to the diagram.

High-configuration display screen

Tablet press workflow diagram

Ø Filling: The filling rail, driven by the filling motor, pulls the lower punch rod downward to achieve the maximum filling amount of the material in the die hole.

Ø Metering: The metering rail (made of tin bronze) pushes the lower punch rod upward, allowing a fixed amount of material to fill the die hole.

Ø Pre-pressure: The upper and lower pre-pressure wheels pre-press the powder, mainly for the purpose of exhausting air and pre-forming.

Ø Main pressure: The main pressure wheel finally compresses the powder into shape. The 150mm diameter main pressure wheel is designed with the same diameter and structure as the pre-pressure wheel, which can be temporarily used interchangeably, resulting in a longer forming time.

Ø Ejection: After the tablet is formed, the lower punch moves upward along the ejection rail, pushing the tablet out. The tablet is then guided by the main body scraper into the acceptable channel.

Note: If it is a defective tablet, it will be blown into the waste channel by compressed air (single tablet rejection is option).

Appearance

The tablet press working chamber is enclosed, ensuring no contamination, easy disassembly, and easy cleaning; the outer surface is flat, smooth, free from scratches and rust; the coating color is consistent, with no bubbling or peeling; the entire unit is made of oil-pulled steel sheet, with good luster and a flat surface; all non-stainless steel parts are treated with polished electroplating; appearance parts are finely processed.

Siemens control system

Ø The main control system adopts the Siemens brand, the servo drive system adopts the Delta brand, and the frequency converter adopts the Schneider brand.

Ø The Siemens S7-1200 PLC control system is employed, which offers faster speeds and complies with 21 CFR PART II. Its ergonomic design is more readily accepted by engineering field personnel.

Ø In terms of hardware, the S7-1200 PLC has faster processing speeds, stronger networking capabilities, enhanced diagnostic and security features. It not only saves costs and improves production efficiency but is also safe, reliable, and easy to maintain, making it the preferred controller for factory clients and on-site maintenance personnel.

Equipment Parameters

Model Parameter | ZTP-200 | ||||

Punch number | 8 | 16 | 20 | 23 | 25 |

Tooling type | D | B | BB | BBS | |

Max. production capacity (pics/h) | 24000 | 48000 | 96000 | 110400 | 120000 |

Max. main pressure(kN) | 100 | ||||

Max. pre-pressure(kN) | 100 | ||||

Max. filling depth (mm) | 18 | ||||

Tablet thickness range (mm) | 0.5~8 | ||||

Max. pressed tablet diameter (mm) | 25 | 16 | 13 | 11 | |

Max. length of irregularly shaped tablet (mm) | <25 | <19 | ≤16 | ≤11 | |

No-load noise (dB) | ≤82 | ||||

Main motor power (kW) | 4 | ||||

Equipment dimensions (mm) | 750×750×1750 | ||||

Packaging dimensions (mm) | 800×800×1800 | ||||

Equipment weight (kg) | 1200 | ||||