ZLJ-125 Mobile Size Reduction Machine Mobile Granulator Uneasy to Damage

- Wonsen

- China

- 120 days

- Strong

The machine is suitable for mill thermal sensitive material and granulating for damp material. It is less the heat and the powder dust.

ZLJ-125 Mobile Size Reduction Machine Mobile Granulator Uneasy to Damage

Introduction

The machine is suitable for mill thermal sensitive material and granulating for damp material. It is less the heat and the powder dust. The sieve of stator is made of stainless steel plate. It is not easy to damage. The gap between mill blade and sieve can be adjusted. Can treat material that is adhesive or in gum or heat or damp state.

Work principle

This machine utilizes the high-speed relative motion between the milling knife and the screen to quickly crush the block shaped materials into granules through the screen holes under the rolling of the milling knife. The finished granules are discharged instantly, with low heat generation, high efficiency, and good quality. Adopting frequency conversion speed regulation, the spindle speed can be adjusted, with a wide range, and using lower drive for smooth feeding. The machine is made of high-quality stainless steel for the parts in contact with materials and the appearance, with a polished surface. It can be used separately with wet granulation machines and fluidized bed drying equipment.

Features

1) Optional lifting mechanism to achieve closed docking with process equipment such as wet granulation machine;

2) Adopting modular design, dry and wet granulation can be achieved by replacing the whole grain knife and sieve. A quantitative feeding mechanism can be configured to improve particle size consistency, and a closed silo can be configured to reduce dust leakage;

3) Three types of whole grain knives, suitable for whole grain processing of various materials with different properties;

4) The sieve mesh has a small aperture of up to 0.4mm, high aperture rate, no dead corners, fine particle size, high material passing rate, which can effectively reduce the occurrence of material heating and is easy to clean;

5) The precision of the sieve aperture is high, and the gap between the whole grain cutter and the sieve can be adjusted, which can control the particle size distribution of the material after granulation;

6) The right angle transmission system and shaft seal technology reduce the risk of material contamination;

7) The entire working cavity has a smooth transition without any dead corners, with smooth material flow, minimal residue, and high yield;

8) The whole machine adopts quick installation clamps for connection, making disassembly and installation simple and fast, and easy for operators to master.

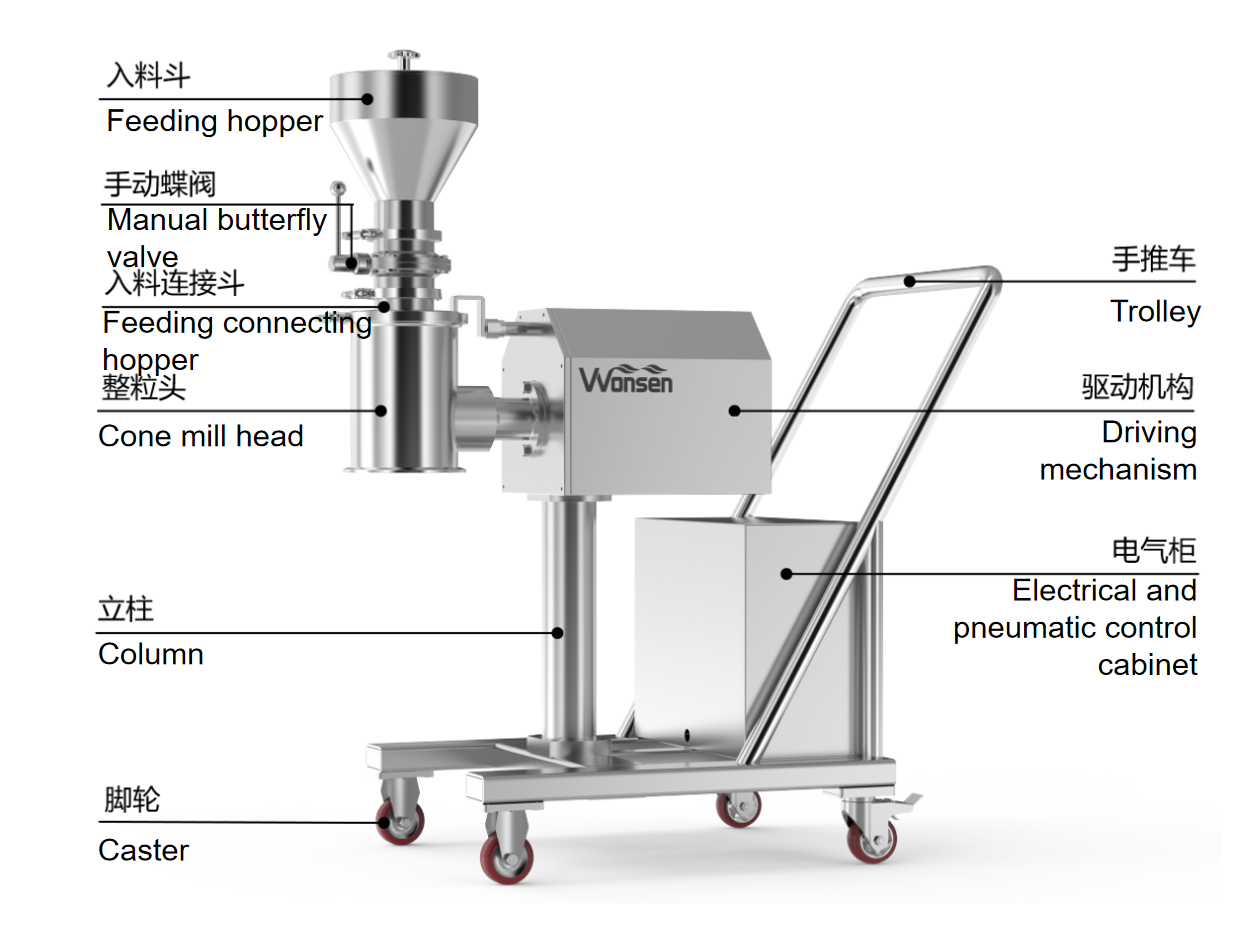

Structure

The mobile granulator mainly consists of a feeding hopper, manual butterfly valve, feeding connecting hopper, milling head, discharging connecting hopper, lifting mechanism (option), column, driving mechanism, electrical cabinet, handcart, and casters.

Components/functions

Parameter description

Remark

Cone mill head

Ø Including cone mill tank, milling knife and screen, etc;

Ø Three types of milling knives (round knife, square knife, toothed knife) are available for different materials;

Ø Circular hole screen specifications: option from 0.4mm to 10mm

Ø The screen is easy to disassemble, clean, and does not clog

Ø The distance between the milling knife and the screen can be adjusted

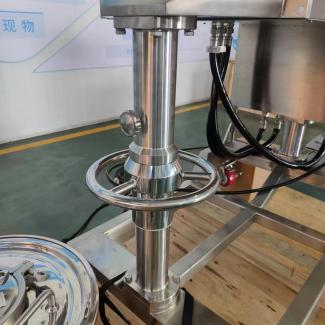

Lifting mechanism (option)

Ø Including columns and handwheels, etc.

Ø Manual rotation of the handwheel allows for free lifting and lowering, achieving a sealed connection with process equipment such as wet granulation machines

Driving mechanism

Ø Including motor, motor cover and main shaft, etc;

Ø Adopting frequency conversion speed regulation, the shaft speed can be adjusted, with a wide range, using lower drive, and smooth feeding;

Ø Option DC motor, servo motor, explosion-proof motor

Electrical and pneumatic control cabinet

Ø Including VFD, circuit breaker, switch power supply, etc;

Ø The wiring inside the electrical and pneumatic control cabinet is simple and reasonable, and the key cables between each electrical component are labeled;

Ø Option explosion-proof electrical cabinet.

Components/functions | Parameter description | Remark |

| Ø Including cone mill tank, milling knife and screen, etc; Ø Three types of milling knives (round knife, square knife, toothed knife) are available for different materials; Ø Circular hole screen specifications: option from 0.4mm to 10mm Ø The screen is easy to disassemble, clean, and does not clog Ø The distance between the milling knife and the screen can be adjusted |

|

| Ø Including columns and handwheels, etc. Ø Manual rotation of the handwheel allows for free lifting and lowering, achieving a sealed connection with process equipment such as wet granulation machines |

|

| Ø Including motor, motor cover and main shaft, etc; Ø Adopting frequency conversion speed regulation, the shaft speed can be adjusted, with a wide range, using lower drive, and smooth feeding; Ø Option DC motor, servo motor, explosion-proof motor |

|

Electrical and pneumatic control cabinet | Ø Including VFD, circuit breaker, switch power supply, etc; Ø The wiring inside the electrical and pneumatic control cabinet is simple and reasonable, and the key cables between each electrical component are labeled; Ø Option explosion-proof electrical cabinet. |

|

Technical parameter

No. | Name | Parameter |

1 | Capacity | ≤250 kg/h (based on bulk density 0.5g/cm³, mesh size 10*10mm) |

2 | Motor power | 2kW |

3 | Power supply | 3PH/380V/50Hz |

4 | Noise | <75dB(A) |

5 | Max. rotation speed | 2000rpm |

6 | Referenced dimension size | Reference drawing |

7 | Referenced weight | 100 kg |

8 | "※" is a reference value, consumption, yield, net weight of equipment, dimensions and other standards for reference only, the actual parameters and materials, configuration, process related. | |