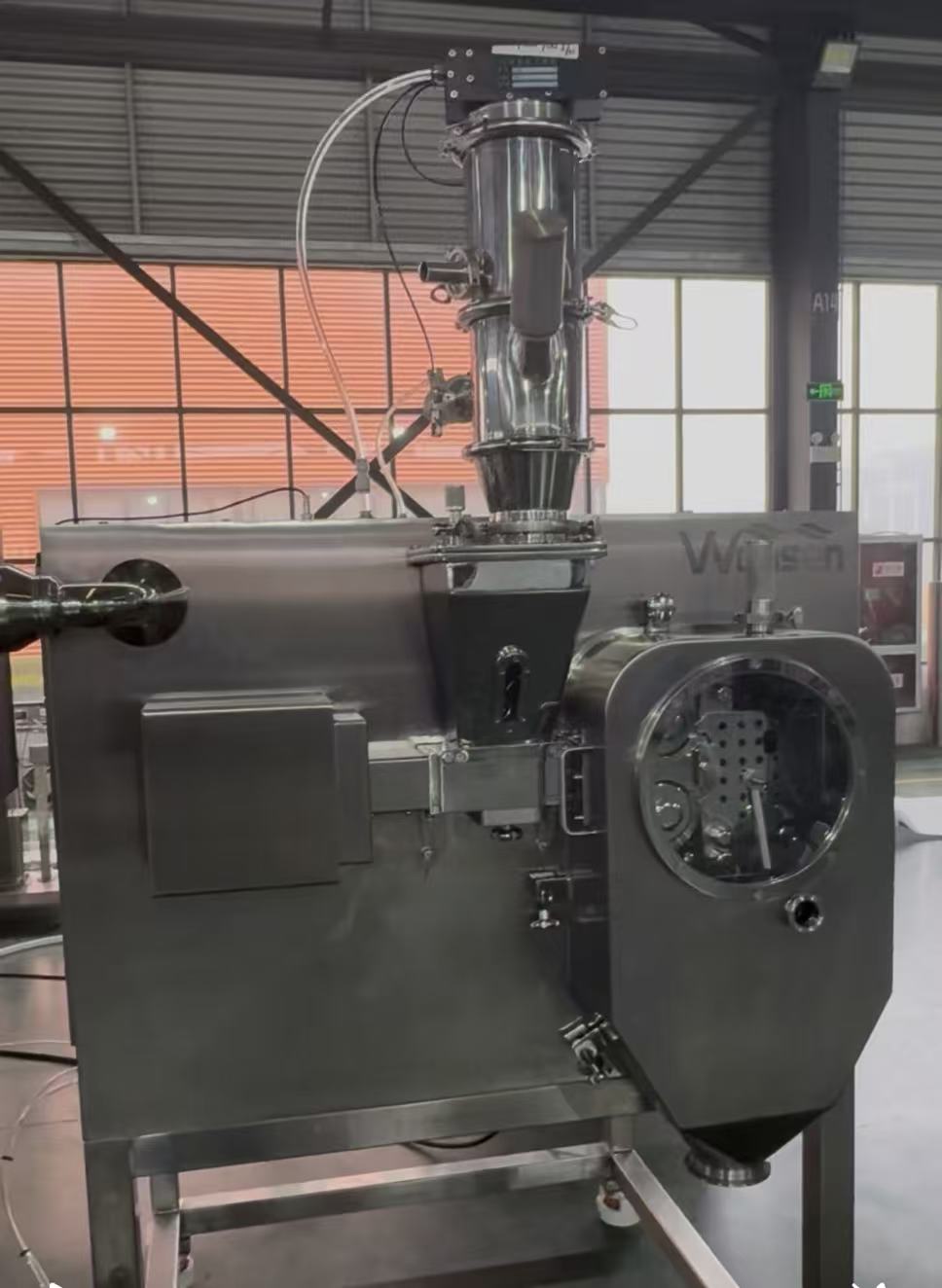

ZKQ-150 Pneumatic Vacuum Feeder CE Approved with a Vacuum Generator for Material Transfer

- Wonsen

- China

- 120 days

- Strong

Pneumatic vacuum feeder is suitable for feeding powder or granular materials to equipment such as mixers, hoppers, tablet presses, granulators, cone mills, wet granulators, dry granulators, and pulverizers.

Main functions and process

The ZKQ series pneumatic vacuum feeder utilizes a vacuum generator for material transfer. Featuring a compact footprint, it is suitable for feeding powder or granular materials to equipment such as mixers, hoppers, tablet presses, granulators, cone mills, wet granulators, dry granulators, and pulverizers. This system significantly reduces labor intensity and eliminates dust spillage issues during the feeding process.

Working Principle

When the “ON/OFF” button is pressed, compressed air is supplied to the vacuum generator and, at the same time, the discharge door of the hopper is closed by the pneumatic cylinder, creating a vacuum inside the hopper.

Under this vacuum, the vacuum loader generates an air stream that conveys the material through the hose into the vacuum hopper.

After a preset loading time (adjustable), the compressed air is shut off, the pneumatic vacuum pump stops producing vacuum, and the discharge door is opened by the cylinder.

The vacuum disappears, so the material drops automatically through the discharge door into the downstream equipment (tablet press, packaging machine, etc.).

Simultaneously, compressed air stored in the air tank back-flushes the filter, cleaning it automatically.

After a preset discharge time (also adjustable), the compressed air is re-introduced, the vacuum generator creates vacuum again, the discharge door closes, and the loader resumes feeding.

This cycle repeats continuously, ensuring a steady flow of material into the receiving equipment.

For vacuum loaders equipped with level control, feeding is fully automatic through a level sensor in the receiving hopper. When the material reaches the high-level probe, the loader stops; when it falls below the low-level probe, the loader restarts, maintaining a consistent charge in the downstream equipment.

Advantages

- Powered solely by compressed air—no mechanical vacuum pump—enabling automatic feeding of any downstream equipment.

- Compact, simple design with low noise, minimal maintenance, easy control and full GMP compliance.

- Fully enclosed pipeline conveying prevents dust emission, protects both product and workplace, and eliminates cross-contamination.

- Interchangeable filter media selected for each specific powder guarantee optimum dust retention.

- Integrated pulse-jet back-flushing system cleans filters automatically, preventing clogging and sustaining filtration efficiency.

- Entire unit built in high-quality stainless steel with polished, crevice-free surfaces for an aesthetic, hygienic finish.

Technical parameter

No. | Item | Parameter(ZKQ-150) |

1 | Capacity | 150kg/h |

2 | Power | 0.014 kW |

3 | Noise | ≤90dB(A) |

4 | Power supply | 1PH/220V/50Hz |

5 | Compressed air consumption | 180L/min |

6 | Compressed air pressure | 0.4-0.6 MPa |

7 | Compressed air inlet tube spec. | Φ10*Φ6 mm,PU tube |

8 | Reference weight | 8kg |