LGP-200 Roller Compactor Dry Granulating Machine with Coordinated Control of Process Parameters

- Wonsen

- China

- 120 days

- Strong

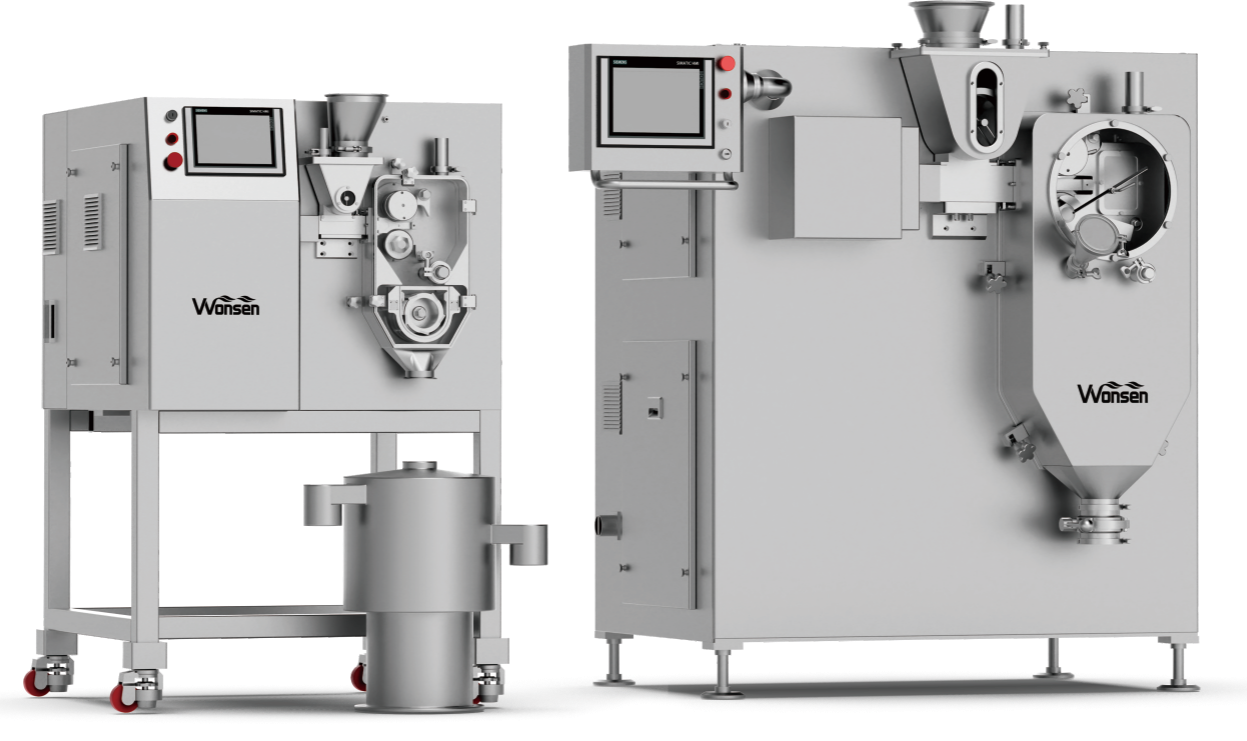

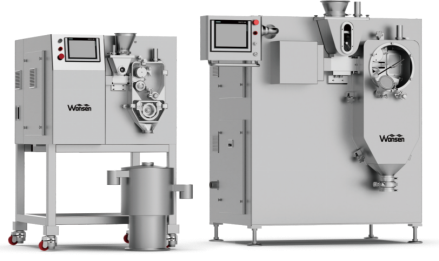

▲3 functions in one unit: compacting, cutting, granulating mill

▲Rollers with a water circulating cooling system

▲Rollers available with different types: smooth, anilox, curle

▲Overall modular design, compact structure, better space utilization

▲With vacuum air exhaust for feeding system

▲Fully meet GMP requirements

▲Control system complying 21 CFR Part 11 requirements

LGP-200 Roller Compactor Dry granulating machine with Coordinated Control of Process Parameters

Introduction

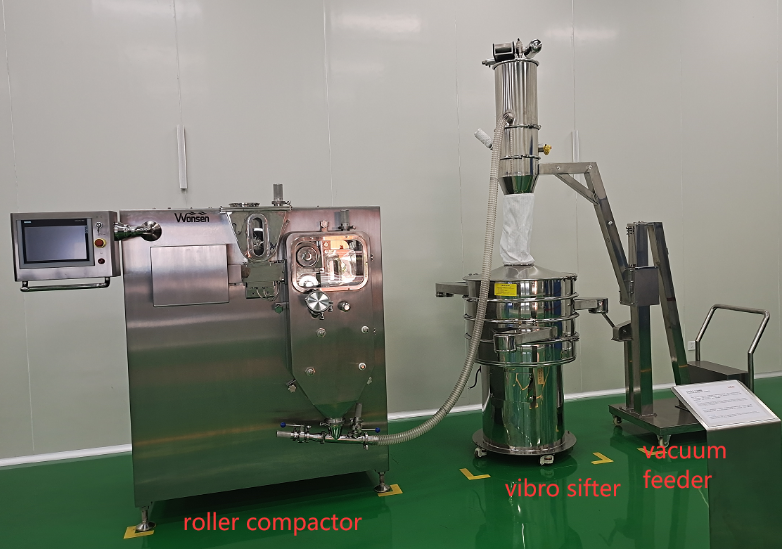

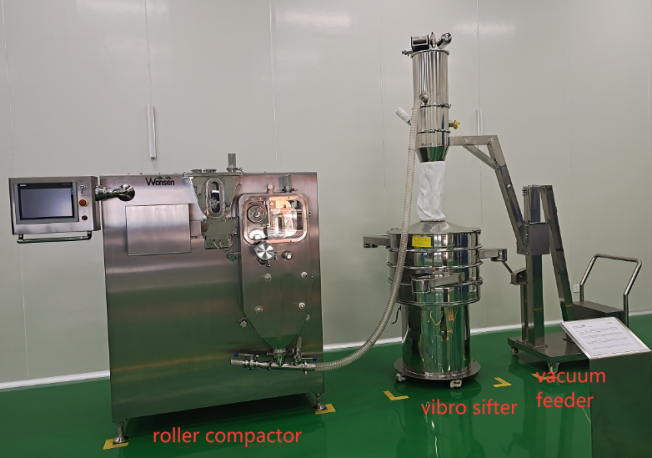

The LGP Series Roller Compactor is an integrated roller compactor system combining feeding, compaction, crushing, granulation and discharging functions, capable of directly converting powder materials into granules. It is particularly suitable for processing moisture-sensitive and heat-labile materials that may degrade or agglomerate. This equipment is widely used in pharmaceutical, food and chemical industries. The granules produced by the Roller Compactor can be directly used for tableting or capsule filling.

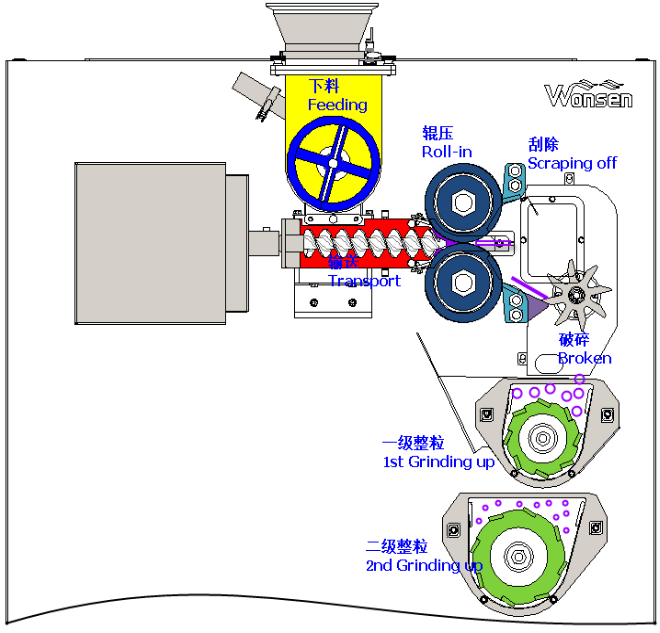

Work principle

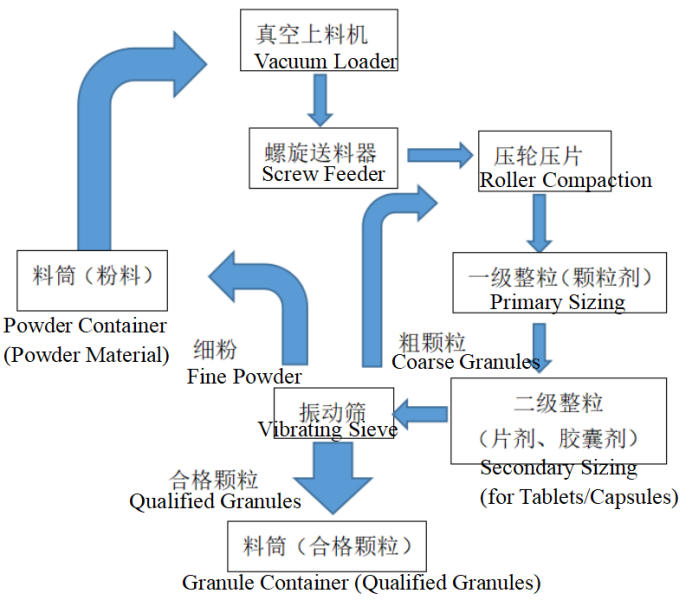

The roller compactor conveys single or multiple mixed powder materials into the hopper via a conveying device, feeds the powder to the extrusion chamber through a horizontal screw, presses the powder into sheets by a pair of vertically arranged pressure rollers, and then processes the sheets into granules through a crushing and granule-sizing system. Finally, the granules are discharged to a vibrating screen via vacuum, and qualified granules are sorted out by the screen.

Process workflow

Process workflow

Features

1) Fully automated PLC control with a color touchscreen HMI for user-friendly operation.

2) Material enters the feed hopper, is homogenized by stirring blades, and conveyed via a speed-adjustable screw feeder.

3) Specially treated parallel rollers enhance material-loading capacity and durability.

The compression chamber is fully sealed and features tempered glass panels for visual monitoring.

4) Rollers incorporate water-cooling to prevent thermal degradation of sensitive materials.

5) Quick-change roller system allows for replacement of rollers with different surface profiles as needed.

6) The main drive motor (roller) uses frequency conversion for stepless speed adjustment, with preset upper/lower limits.

7) All material-contact components are constructed of stainless steel or food-grade polymers.

8) Roller pressure and gap settings are displayed and adjustable via the touchscreen interface.

9) The granulation unit accepts interchangeable screens to achieve varying particle sizes.

10) Adjusting the speed ratio between screw feeder and rollers modifies particle thickness and hardness/density.

11) Features include parameter presets, password protection, fault alarms, and help menus.

12) Horizontal screw feeder with unique cantilever design expands material compatibility and improves yield.

13) Water-cooled rollers prevent material property changes due to temperature rise during processing.

14) Rollers are manufactured from specialty stainless steel with hardened surfaces for high wear resistance.

15) Full stainless steel construction (316L for contact parts, 630 for critical areas) complies with pharmaceutical GMP requirements.

16) The feeder is designed with a vacuum exhaust port, which can effectively discharge the air in the material when the screw is feeding, so that the feeding is more compact. Unique vacuum exhaust system, does not cause equipment temperature rise.

17) The working area is separated from the transmission area to achieve clean and closed production from powder to granules, effectively preventing dust and cross contamination, and all parts in contact with materials are easy to disassemble and clean.

Technical parameter

No. | Parameter name | Parameter content (LGP-200) |

1 | Roller size (mm) | 200×75 |

2 | Granule size (mm) | 0.18-2.0 |

3 | Loading capacity (kg/h) | 50-200 (calculated based on referenced lactose powder with a density of 0.5g/cm³, the final capacity depends on user own material characters,it can deal with 100kg output based on 14 mesh sifter mesh size) |

4 | Linear pressure (KN/cm) | 30KN/cm |

5 | Screw feeding rotation speed (rpm) | 0-180 |

6 | Roller rotation speed (rpm) | 0-27 |

7 | Mixing rotation speed (rpm) | 0-80 |

8 | Granulating rotation speed (rpm) | 0-120 |

9 | Crusher rotation speed (rpm) | 0-200 |

10 | Screw feeding motor power (kW) | 2.2 |

11 | Roller motor power (kW) | 7.5 |

12 | Granulating motor power (first stage) (kW) | 0.75 |

13 | Granulating motor power (second stage) (kW) | 1.5 |

14 | Mixing motor power (kW) | 0.37 |

15 | Crushing motor power (kW) | 0.25 |

16 | Hydraulic pump station power (kW) | 1.5 |

20 | One-time yield (0.18-2.0mm granules) | ≥65% |

21 | Final yield | ≥98% |

22 | Power supply | 3PH/220V/50Hz |

23 | Compressed air pressure (Mpa)※ | 0.4-0.6 |

24 | Compressed air consumption (L/min)※ | 1120 |

25 | Compressed air tube | Φ12*8 |

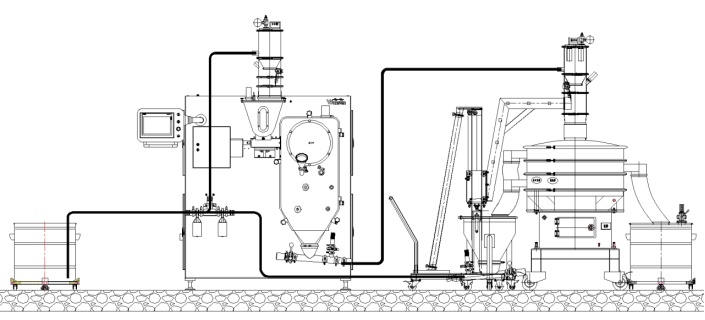

26 | Reference outline dimension (mm) | Please refer to the drawing |

27 | Reference total weight (kg) | 2600 |

"※" indicates that these values are for reference only. Consumption, yield, net weight of equipment, and external dimensions are company standards for reference purposes only. The actual parameters are related to materials, configurations, and processes. For production capacity, for example, lactose is taken as an example; other materials are related to density, fluidity, and compressibility. | ||