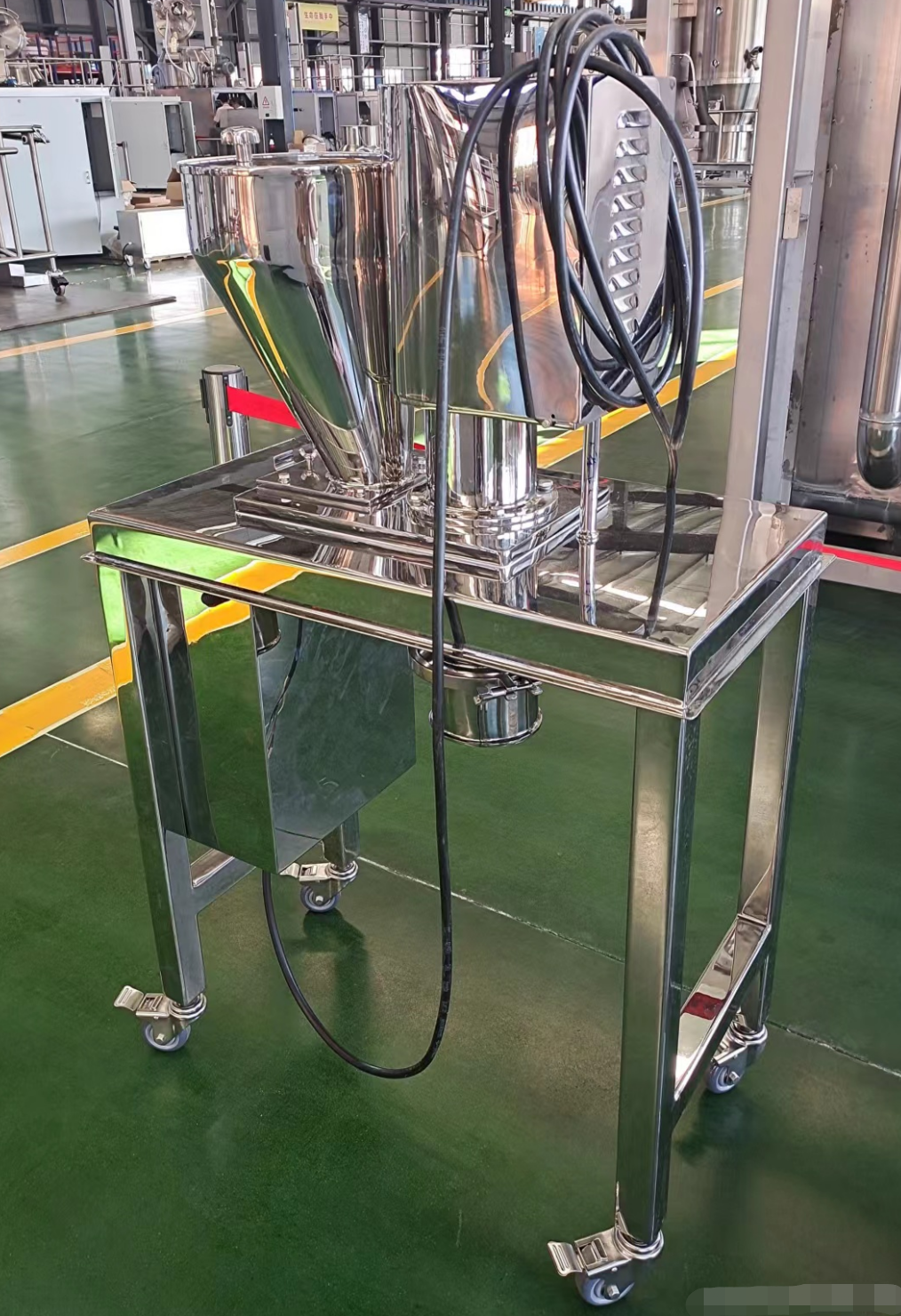

FZM-300 Grinding Dry Cone Mill Crushing of Raw Materials Granulating of Wet Materials Granule Sizing of Dry Materials

- Wonsen

- China

- 120 days

- Strong

① It thoroughly solves the problem of scraps polluting materials due to the wear of the screen in the oscillating granulator.

② The unique shaft sealing patented technology ensures no leakage of lubrication oil.

FZM-300 Grinding Dry Cone Mill Crushing of Raw Materials Granulating of Wet Materials Granule Sizing of Dry Materials

Application

Medicine: crushing of raw materials; granulating of wet materials; granule sizing of dry materials; as for nonconforming medicines, granule sizing can be carried out according to the requirements for granule size; food: recovery and utilization after crushing of biscuits; others: crushing and granule sizing of rough raw materials and crushing and granule sizing of block raw materials.

Work principle

Add the raw materials into the crushing machine hopper. After dropping into the conical work chamber through the adjustment by the gate valve, the raw materials are subject to vortex action by the rotary granule sizing knife, and the granules are thrown to the screen by the centrifugal force. Meanwhile, shearing effect is produced on the screen due to the high speed rotation of the rotary knife, and the granules are crushed into small granules between the rotary knife and the screen and discharged through the screen mesh. The size of crushed granules is adjusted through the meshes of the screen, the distance between the rotary knife and screen and the rotation speed.

Note: The raw materials can also be feeding into the crushing machine hopper by the pneumatic vacuum feeder.

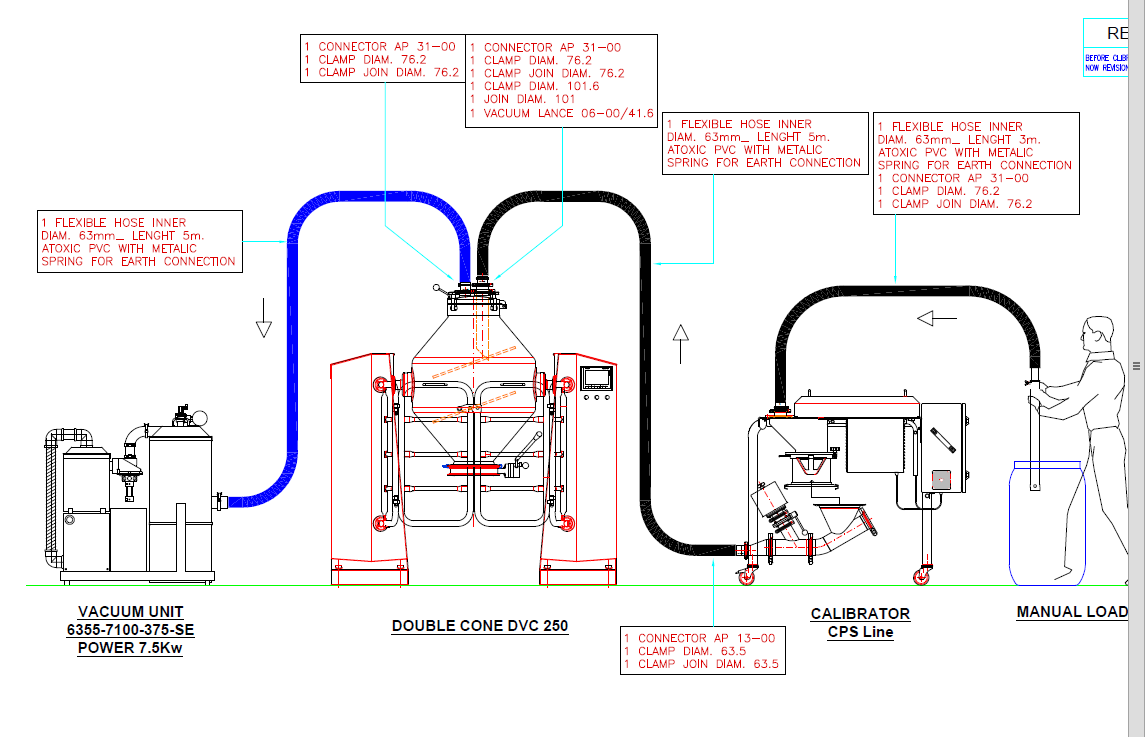

Closed line

Features

1) It thoroughly solves the problem of scraps polluting materials due to the wear of the screen in the oscillating granulator.

2) The unique shaft sealing patented technology ensures no leakage of lubrication oil.

3) The granule size is easy to control.

4) There is no retention dead corner and no overheating of materials.

5) Little dust, no vibration and low noise.

6) High efficiency, energy saving and high production capacity.

7) With beautiful appearance, it is easy to clean.

8) With convenient movement, it has a wide application range.

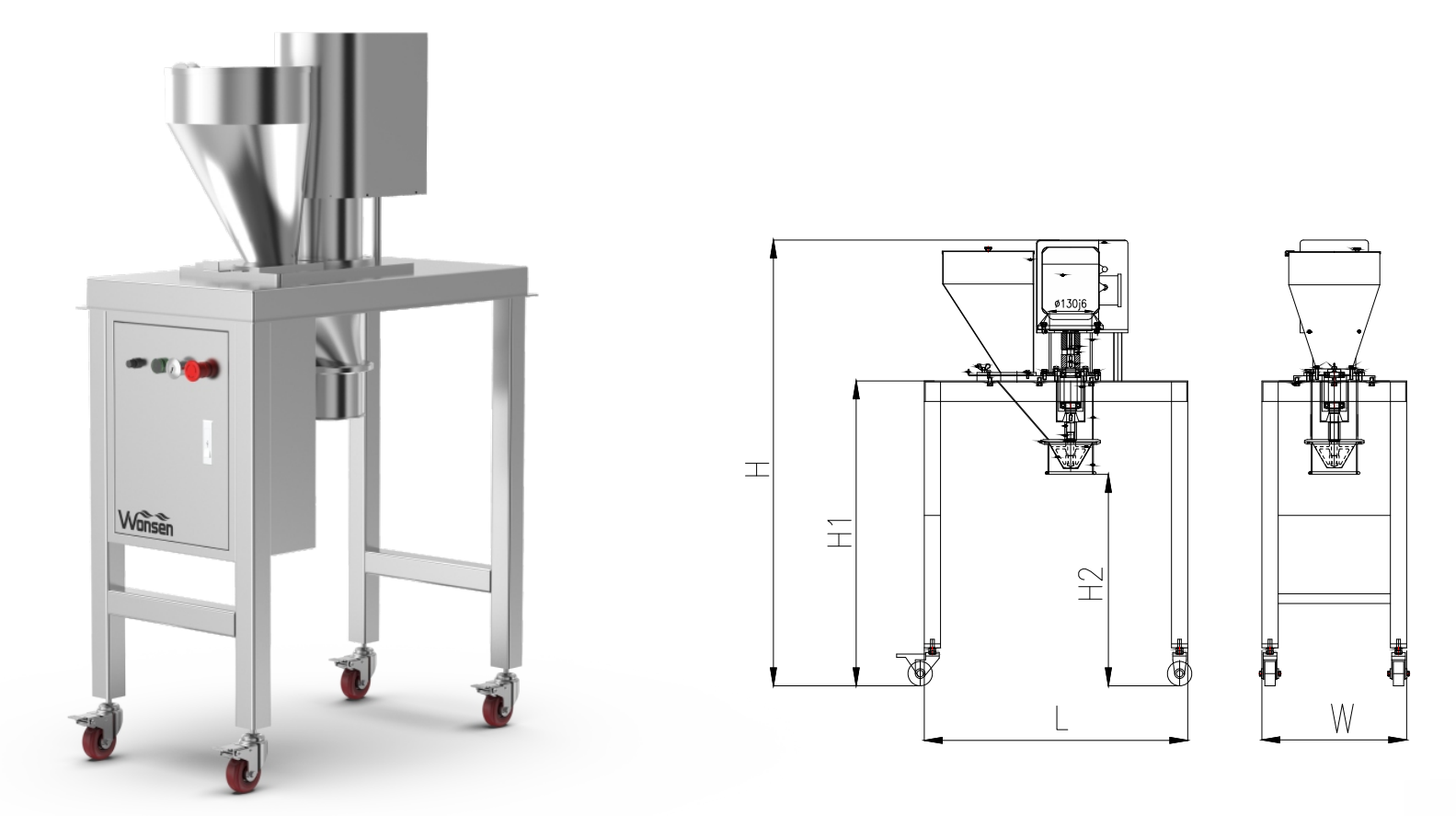

Technical parameter

No. | Name | Parameter |

1 | Max co-mill capacity | 300kg/h |

2 | Co-mill power | 2.2kW |

3 | Co-mill rotate speed | 300~2800 rpm |

4 | Height of the discharge port off to ground | 650mm |

5 | Power supply | 3PH/380V/50Hz or customized based on user actual condition |

6 | 参考外形尺寸※ Referenced dimension size※ | According to the actual drawing |

7 | “※”表示为参考值,耗量、收得率、设备净重、外形尺寸等为公司标准只作参考,实际参数与物料、配置、工艺有关。 "※" is a reference value, consumption, yield, net weight of equipment, dimensions and other standards for reference only, the actual parameters and materials, configuration, process related. | |