AM-50&AM-100 Air Jet Mill No Dust Leakage Crushing Machine

- Wonsen

- China

- 120 days

- Strong

The machine is suitable for all kinds of brittle, crystalline, heat sensitive, medium and low hardness materials dry ultrafine grinding.

AM-50&AM-100 Air Jet Mill No Dust Leakage Crushing Machine

Introduction

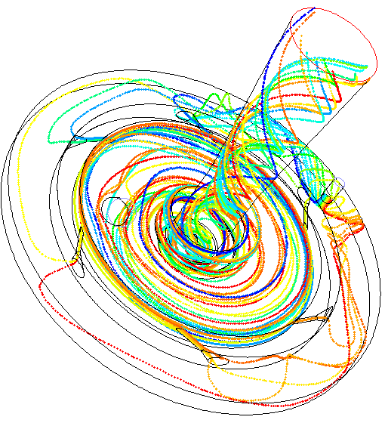

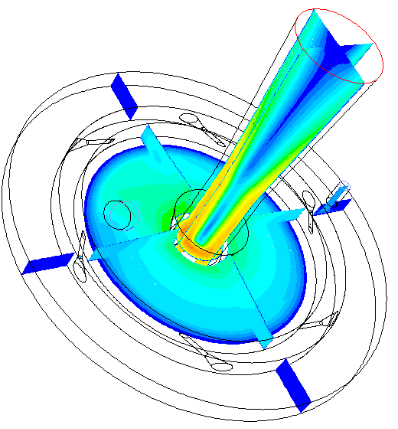

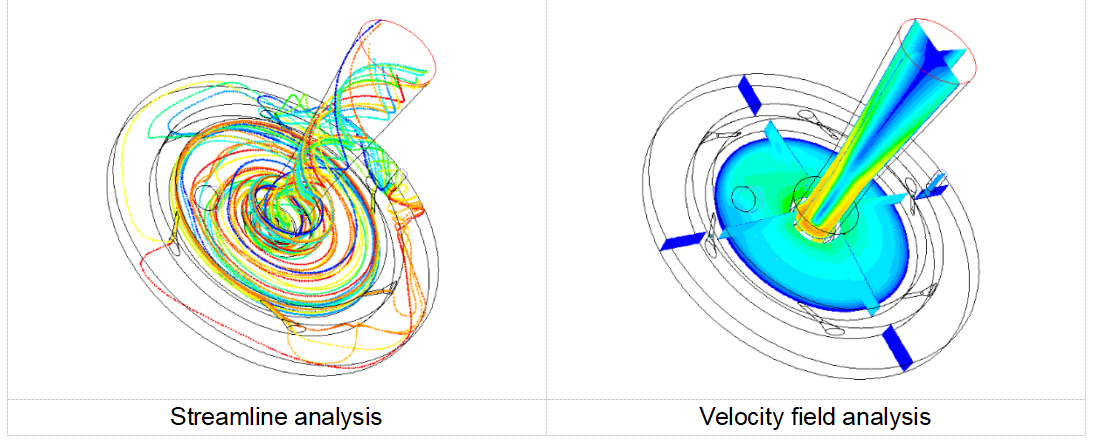

The granules enter the milling chamber, and through the distribution of the nozzle matrix in the periphery, the granules generate acceleration and carry out spiral movement up to 300 m/s. When the input speed of the slower granules and the spiral movement of the faster granules collide, that is, the micro-powder effect. At the same time, under the action of centrifugal force, larger granules move around the periphery of the milling chamber, and smaller granules leave from the center of the chamber with the process gas.

Work principle

Feeding material: The raw material is uniformly fed through the double screw feeder, and the negative pressure generated by the gas injected through the feeding port is sucked into the milling chamber.

Milling: The material rotates at high speed in the chamber along the set direction, causing the material to collide with each other and friction, grinding the material.

Collecting: Most of the ultrafine material after being milled goes into the storage container.

Dust removal: A very small part of the material is taken to the dust collector, after filtration, clean air discharge.

Application

①Suitable for all kinds of brittle, crystalline, heat sensitive, medium and low hardness materials dry ultrafine grinding.

②Used in chemical, pharmaceutical, food and other industries, high efficiency, no dust leakage.

③The milling of various granules with the target particle size between 1 and 50μm.

Features

①The surface in contact with the material is electrolytic polished, and the surface roughness is less than 0.4μm.

②Easy to load and unload for fast cleaning and cleaning verification. This feature is critical for the pharmaceutical industry, which must comply with CGMP requirements. All components can be cleaned in an ordinary ultrasonic cleaner. Mirror polished surface, regular, no screws used (quick connector instead)

③Low temperature medium free milling, especially suitable for heat sensitive, low melting point, sugar content and volatile materials grinding.

④The whole system is closed and pulverized, less dust, low noise, and clean and environmentally friendly production process.

⑤The modular design makes it easy to move and carry a true laboratory unit with a variety of portable accessories (nitrogen cylinders, travel cases, high-precision feeders).

⑥Extremely narrow particle size distribution curve.

⑦The entire milling system maintains stable and balanced pressure control.

⑧No air flow blowback phenomenon, there will be no pollution of large granules.

⑨The contact surface with raw materials is greatly reduced, the internal surface of the equipment is cleaned quickly, and the loss rate of the product is small.

⑩The viscous powder can be prevented from forming layers in the milling chamber.

Technical parameter

(AM-50)

Item | Unit | Parameter | |

Milling chamber diameter | mm | 50 | |

Capacity | Kg/h | 0.035-0.1 | |

Batch capacity | II collection system | Kg | 0.0015-0.5 |

Air consumption※ | 0.7MPa | Nm³/min | 0.2 |

1.2MPa | 0.35 | ||

Raw material particle size | mm | ≤1 | |

Double screw diameter | mm | 10 | |

Double screw speed | r/min | 1-300 | |

Conveying capacity | Kg/h | ≤3.5 | |

Double screw motor power | kW | 0.1kW (servo motor) | |

Milling particle size | μm | 1~50 | |

Power supply | / | 3PH/380V/50Hz | |

Air source | MPa | 0.7~1.2 | |

Noise | dB | ≤75 (Measure one meter away from the equipment) | |

Power | kW | 0.2 | |

Referenced dimension size (L*W*H)※ | mm | 900*500*1700 | |

"※" is a reference value, consumption, yield, net weight of equipment, dimensions and other standards for reference only, the actual parameters and materials, configuration, process related. | |||

(AM-100)

Item | Unit | Parameter | |

Milling chamber diameter | mm | 100 | |

Capacity | Kg/h | 0.05-5 | |

Batch capacity | II collection system | Kg | 0.1- 8.0 |

Air consumption※ | 0.7MPa | Nm³/min | 0.412 |

1.2MPa | 0.706 | ||

Raw material particle size | mm | ≤3 | |

Double screw diameter | mm | 20 | |

Double screw speed | r/min | 1-200 | |

Conveying capacity | Kg/h | ≤5 | |

Double screw motor power | kW | 0.2kW (servo motor) | |

Milling particle size | μm | 1~50 | |

Power supply | / | 3PH/380V/50Hz | |

Air source | MPa | 0.7~1.6 | |

Noise | dB | ≤75 (Measure one meter away from the equipment) | |

Power | kW | 0.4 | |

Referenced dimension size (L*W*H)※ | mm | 1493*820*1954mm (secondary receiving) | |

"※" is a reference value, consumption, yield, net weight of equipment, dimensions and other standards for reference only, the actual parameters and materials, configuration, process related. | |||