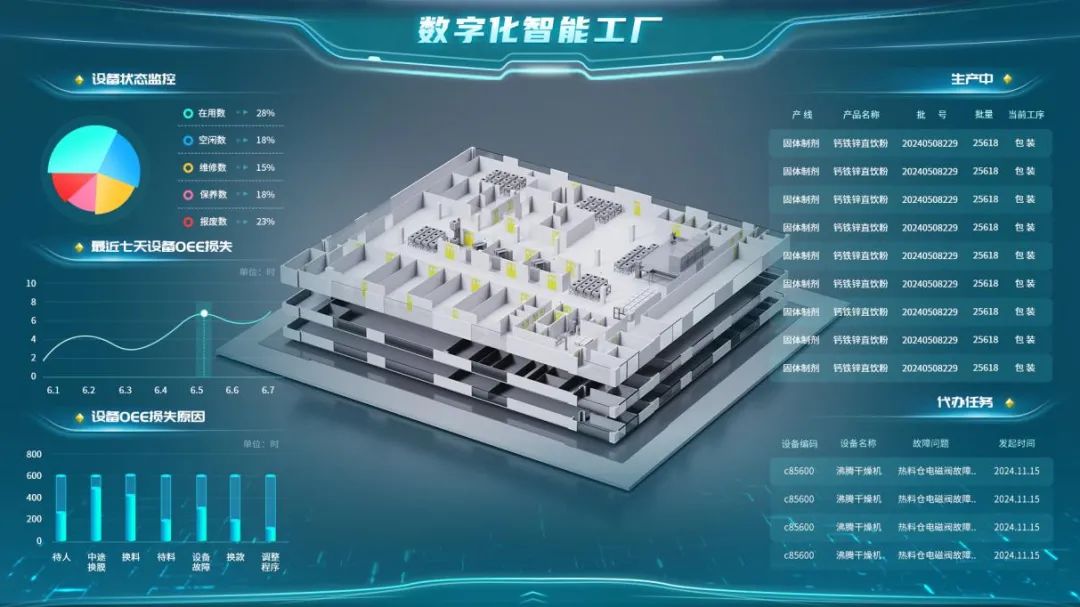

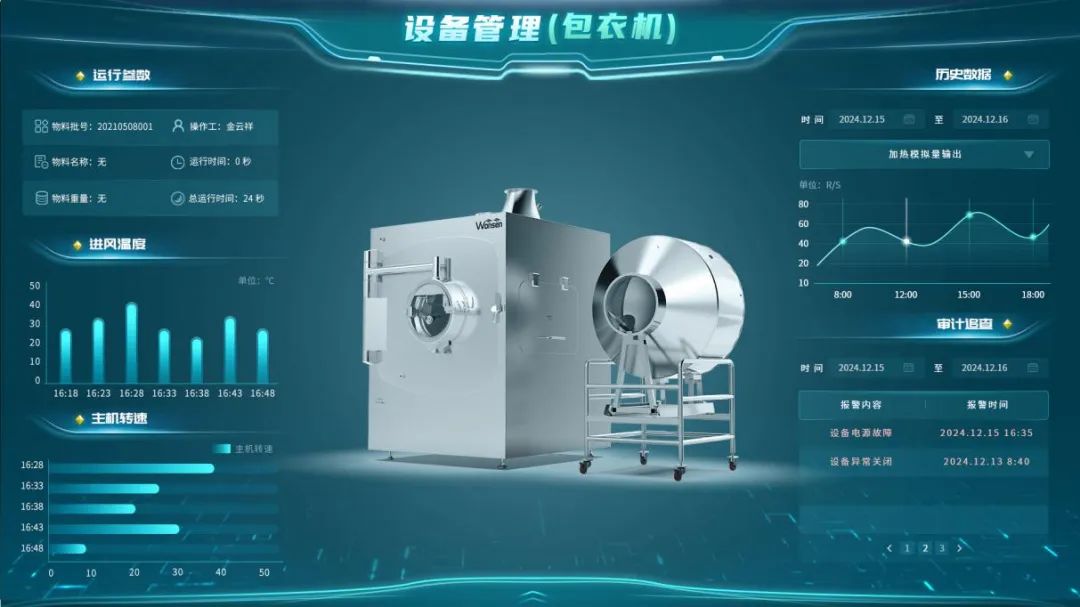

Wonsen SCADA system

The Wonsen SCADA system collects process parameters, utility parameters, environmental parameters, video surveillance and other data in real-time through a unified data interface. The data is stored and backed up uniformly to ensure that all key data can be queried and traced, meeting the requirements of data integrity and consistency. The data is analyzed and displayed through a 2.5D visual interface, allowing for real-time monitoring of equipment operation status and achieving full process transparency and visual kanban management of ingredients, granulation, drying, mixing, tablet pressing, coating, cleaning, packaging, warehousing, etc. It also supports desktop/web/mobile multi terminal access.

In addition, the system can serve as a monitoring and scheduling center for equipment, a batch and formula distribution center, and a report analysis output center. The formula management function can quickly switch production modes and reduce manual operation errors based on the production formulas of different dosage forms such as tablets, capsules, granules, and pills. It can automatically generate electronic batch records, associate production formulas, operators, and equipment parameters, and support one click traceability of the root cause of quality problems. And provide data depth secondary analysis functions (such as OEE calculation, gold batch analysis, etc.), generate intelligent reports for the entire production line, and provide strong support for enterprise decision-making optimization.

- Rapid mixing granulator

- SHLG high shear mixing granulator

- SHL wet type mixing granulator

- SHLS lab wet type mixing granulator

- Top Drive Wet Type Rapid Mixer Granulator

- Drying machine

- FG Fluid bed dryer

- FL Fluid bed granulator

- DPL Multi-functional fluid bed dryer-granulator-coater

- DPLS Multi-functional fluid bed dryer-granulator-coater

- Mixer / bin blender

- ZTH Auto lifting mixer

- HLT Single-column lifting mixer

- HLS Lab scale mixer

- HF Square cone mixer

- Vertical Bin Blender

- Horizontal ribbon mixer

- High efficiency coating machine

- BGB-D High efficient coating machine with CIP

- BGB-C High efficent coating machine

- BGF New Coating machine with interchangeable pans

- BGB-F Lab coating machine

- BGB-M Containment coating machine

- IBC Bin

- HZT Automatic mixing transfer bin

- HZTD Single column lifting mixing bin

- ZT Square cone IBC bin