ZS series Three-D Rotary Vibro Sifter with Low Noise and High Efficiency

- Wonsen

- China

- 120 days

- Strong

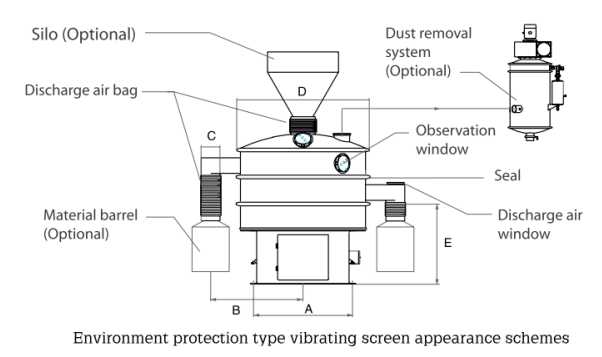

1)Materials can be closed transportation, screening, reduce labor intensity, no dust, low noise, clean production process and environmental protection.

2)Multi-layer screen can be set as required to screen particles of different specifications, flexible operation.

ZS series Three-D Rotary Vibro Sifter with Low Noise and High Efficiency

tin soldering screen with the sifter frame, integrated structure, more easily to replace & clean, material 316L

Bouncy balls under the sieve screen

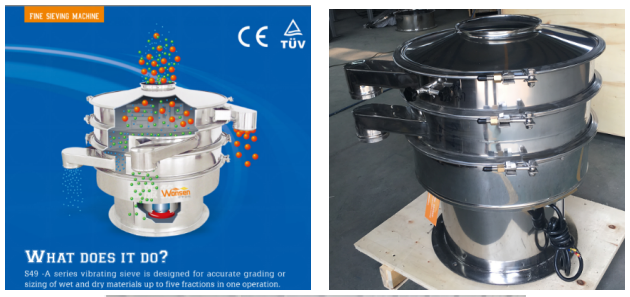

Introduction

ZS series Three-D Rotary Vibro Sifter is one of precise powder sieving machine,low noise,high efficiency,which only needs 3-5 minutes to rapidly replace the screen,all closed structure. Used to sieve granules,powder and mucilage.

The vibro sifting system is an intelligent environmental screening system integrating feeding, feeding and screening. It can remove some impurities contained in the powder within a short time and screen out the powder in line with the process requirements. The whole screening process adopts automatic control, sealed transportation, no dust, the production process is clean and environmental protection. It can also achieve satisfactory screening effect for materials with high viscosity, high fiber and high mesh number. It is widely used in food, medicine, chemical industry and other industries.

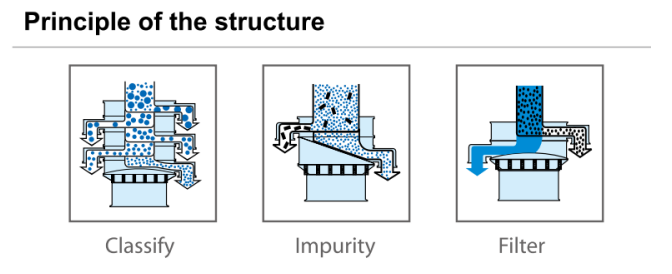

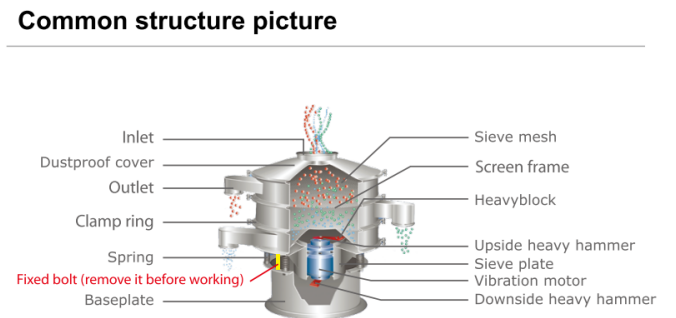

Work principle

The system is composed of optional vacuum feeder, soft connecting device, dust-free rotary vibrating screen, discharging device and operating platform. The material is sucked the rotary vibrating screen by the vacuum feeding machine. The vibration motor outside the rotary vibrating screen are used to generate vibration, so that the material particles of the required size can enter the next process through the screen. The size of sifting material particles is determined by the mesh number of the screen. The multi-layer screen can be flexibly set according to the need of screening particles of different specifications.

Optional vacuum feeder with lifting column to adjust the feeding height

Feature

1) Compact structure design, small size, does not take up space, easy to move, not limited by the region.

2) Materials can be closed transportation, screening, reduce labor intensity, no dust, low noise, clean production process and environmental protection.

3) Multi-layer screen can be set as required to screen particles of different specifications, flexible operation.

4) It is made of 304/316l stainless steel, the inner surface is smooth without powder, and it meets the requirements of GMP.

Technical parameter

Subject to the exact configuration and optional items of the specific model.