Small Scale Granulation Machine (Dry Process) for Tablet Formulation

Small Scale Granulation Machine (Dry Process) for Tablet Formulation

- Wonsen

- China

- 120 days

- Strong

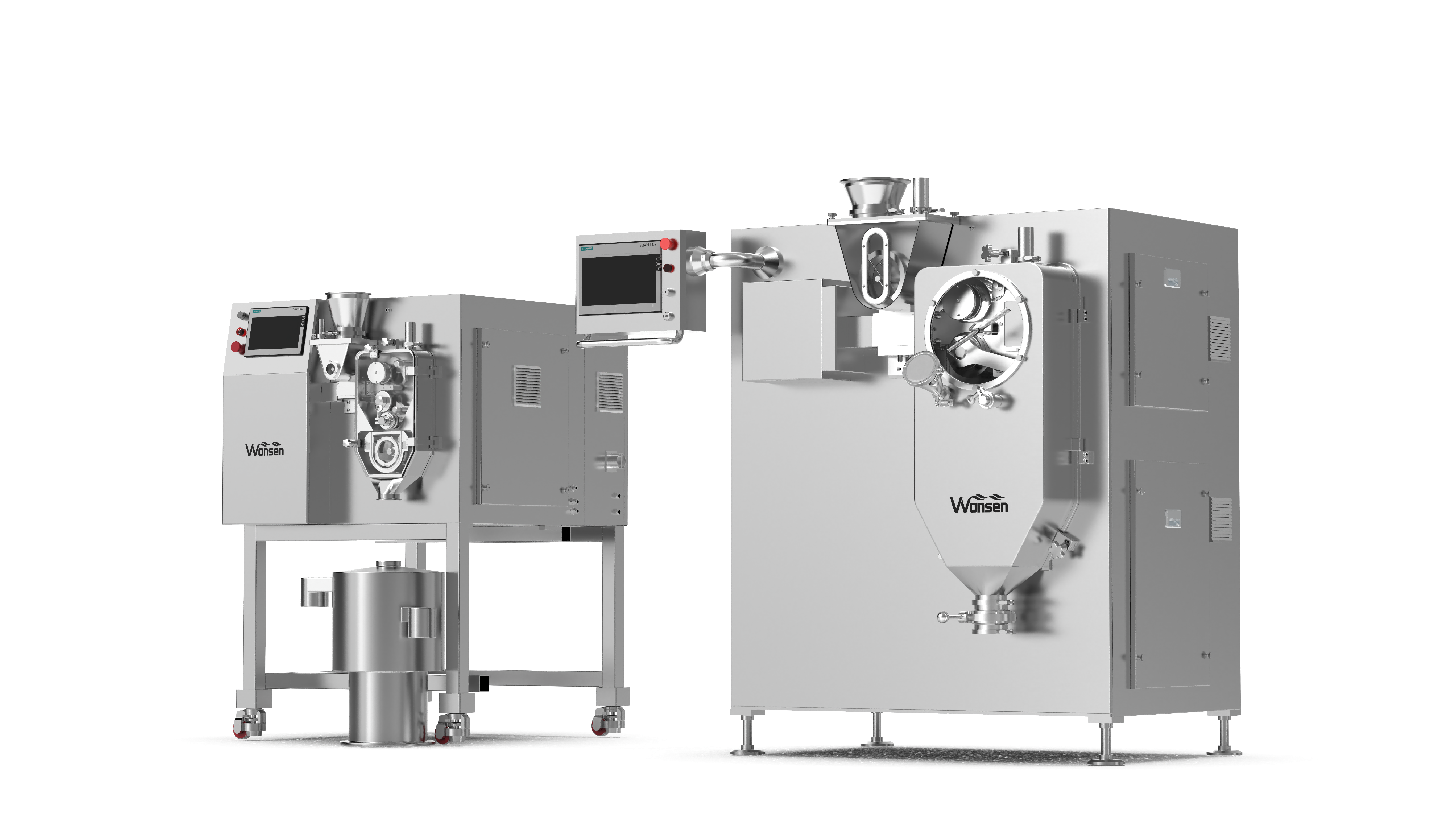

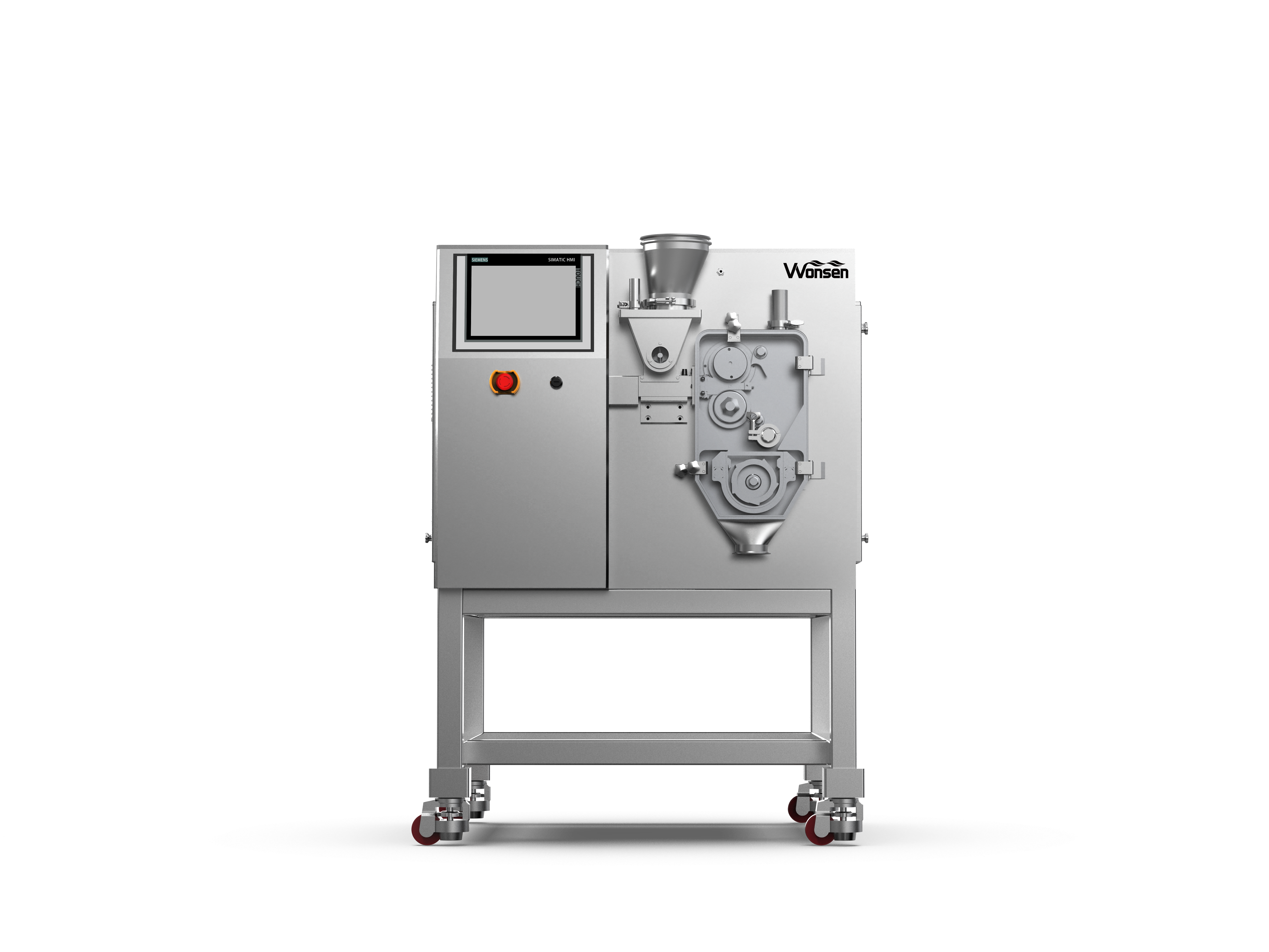

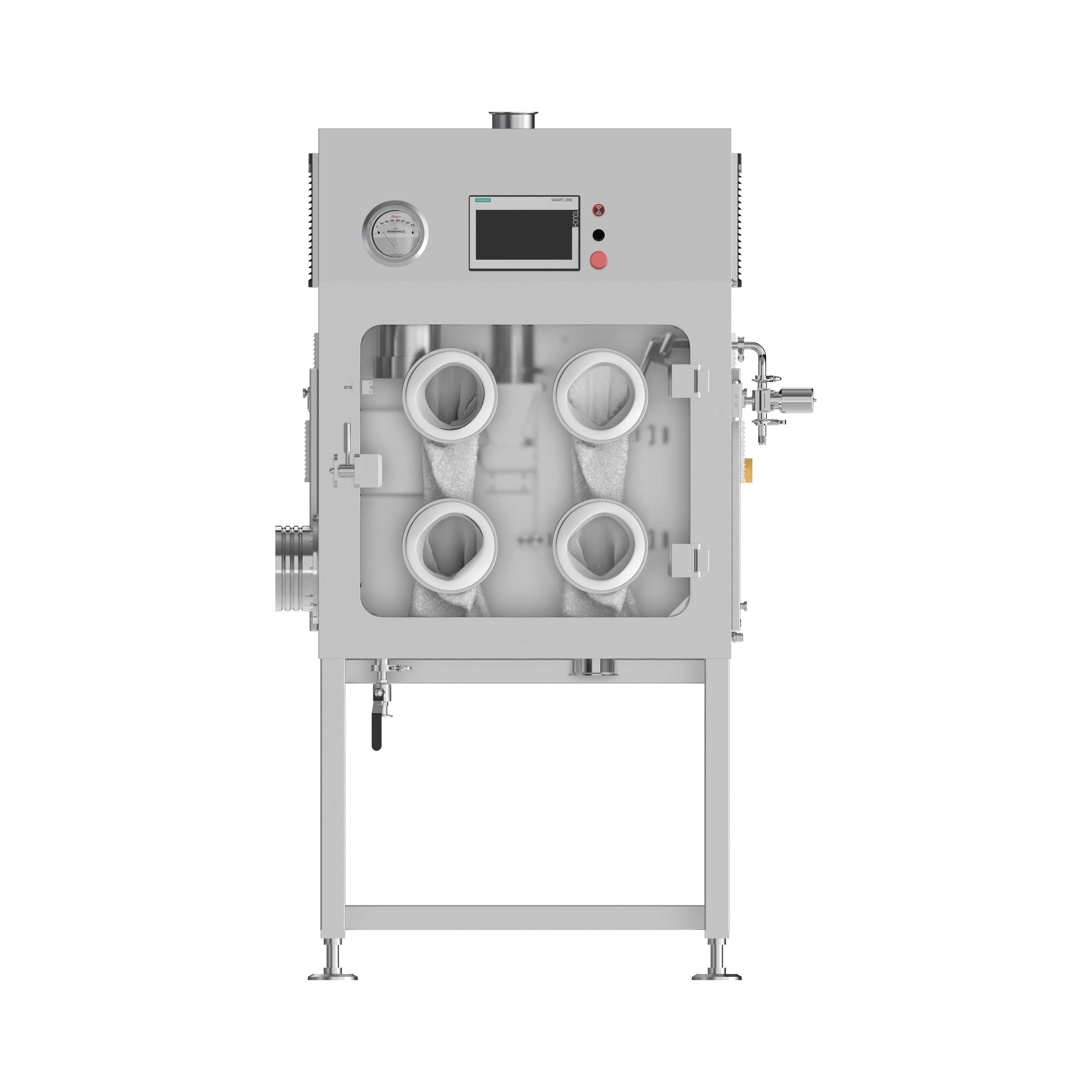

Roller Compactor

Compactor Roll Double Roller extrusion

Roller extrusion granulating machine

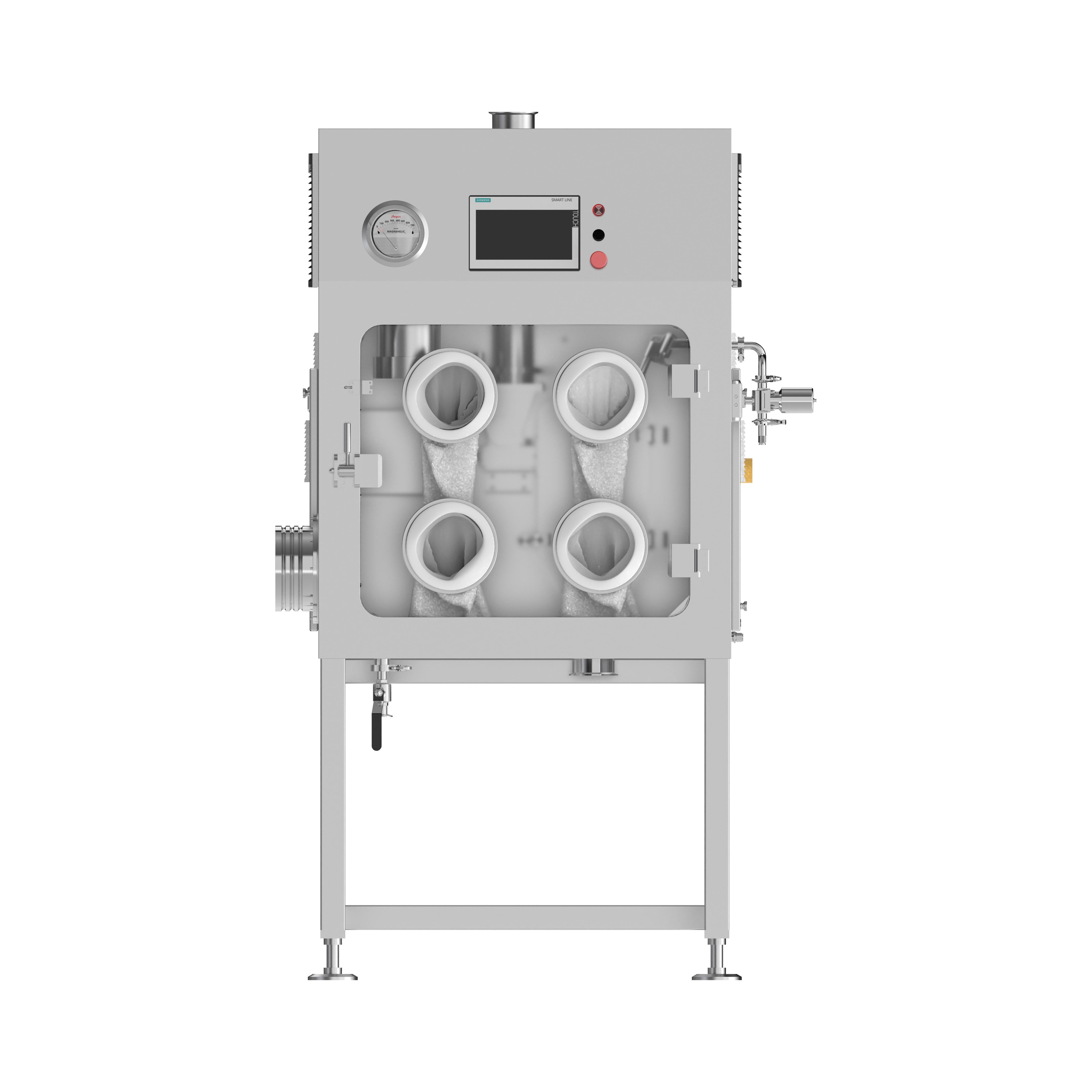

OEB5

Products Description

Main technical parameters

Main technical parameters

Roller size 100*20mm

Granules size 0.18-2.0mm

Granules size 0.18-2.0mm

Loading capacity 0.05~ 15kg/h

(calculated based on referenced lactose powder, final product production capacity based on customer’s material characters)

Screw feeding speed 0-140rpm

Mixing speed 0-70rpm

Roller speed 0-23rpm

Granulating speed 0-140rpm

(calculated based on referenced lactose powder, final product production capacity based on customer’s material characters)

Screw feeding speed 0-140rpm

Mixing speed 0-70rpm

Roller speed 0-23rpm

Granulating speed 0-140rpm

Max compacting pressure of rollers 23 Mpa (35.8 kN/cm)

Screw feeding motor power 0.75kW

Roller motor power 1.1kW

Granulating motor power 0.55kW

Mixing motor power 0.18kW

Hydraulic station motor power 1.5kW

Crushing motor power 0.4kW

Referenced outline dimension 1075*1230*1590mm

One time granules collection rate (0.18-2mm granules) ≥65%

Final grain yield ≥98%

Screw feeding motor power 0.75kW

Roller motor power 1.1kW

Granulating motor power 0.55kW

Mixing motor power 0.18kW

Hydraulic station motor power 1.5kW

Crushing motor power 0.4kW

Referenced outline dimension 1075*1230*1590mm

One time granules collection rate (0.18-2mm granules) ≥65%

Final grain yield ≥98%

Main functions and process

Main functions and process

LG series Roller compactor adopts continuous loading, discharging, integrates compacting, crushing (only applicable to LG-30 and above models) and granulation functions, directly compacting powder into granules. It is especially suitable for granulation of materials which are thermo-sensitive and humidity sensitive, easily broken down or agglomerated. It has been widely used in pharmaceuticals, food, chemicals and other industries. In the pharmaceutical industry, granules made by roller compactor can be directly pressed into tablets or filled into capsules.

Certificates

Our Advantages