Pharmaceutical Square Cone Mixer and stainless steal blender

- wonsen

Large capacity

Human/ machine/ product safety

High automation and efficient blending

Simple operation and easy to clean

Pharmaceutical Suqare Cone Mixer and stainless steal blender

Pharmaceutical Suqare Cone Mixer and stainless steal blender

Application

Researched and developed according to the features of various types of mixers, the square cone mixer is a mixer with very wide application. It fully meets GMP requirements and other relevant industry standards. It is especially suitable for processes of products with relatively simplex varieties and relatively large batches, such as the mixing of solid preparations in such industries as medicine, food, dairy products, chemical reagents, etc.

Work principle

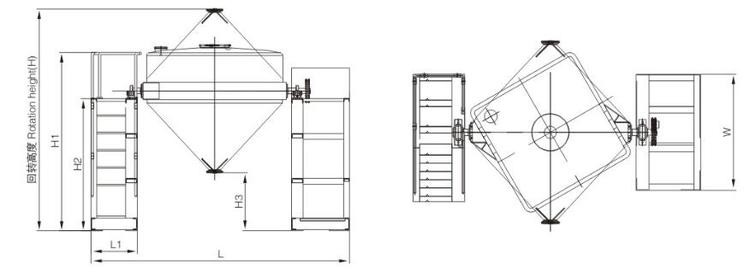

The materials enter the mixing barrel through manual feeding, vacuum feeding, floor material dropping or special lifting machine. As the symmetrical axis of the hopper forms an included angle with the rotation axis, different components of materials will make three-dimensional movement in the closed hopper, producing strong turning, diffusing and shrinking actions and achieving the best mixing effect.

Features

With novel design, compact structure and beautiful appearance, the machine can reach mixing evenness of 99% and volume loading coefficient of 0.8. It has such features as high rotation height, stable running, reliable performance and convenient operation. The inner and outer walls of the barrel are subject to mirror polishing with easy discharging and easy cleaning and without any dead corners and cross contamination, meeting GMP requirements.

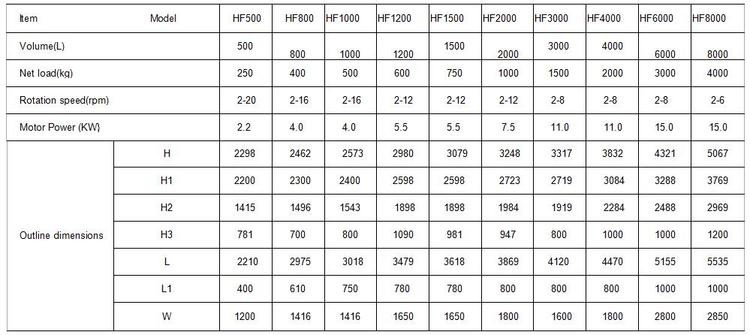

Technical Parameter

Raw Materials

Production Flow

Part of Production & Inspection Equipment

Our Company View

Exhibitions and Customers

FAQ

1.How long for the delivery?

Within 45 days after receiving the deposit.

2.What's the payment terms?

T/T, L/C,Cash,West union etc.

3.OEM and ODM?

Yes

4.How long is the warranty period?

One year after shipment

Welcome to contact us