LGP-100 Roller Compactor Extrusion Granulator:Innovation in Pharmaceutical and Industrial Processing

- Wonsen

- China

- 120 days

- Strong

▲PLC automatic control, color touch screen human-machine interface is friendly, easy to operate.

▲After the material enters the feeding hopper, it is stirred by the mixing impeller and enters the screw feeder, which is fed by the screw and the rotation speed is continuously adjustable;

▲fully meets the GMP requirements of drug production

LGP-100 Roller Compactor Extrusion Granulator:Innovation in Pharmaceutical and Industrial Processing

Introduction

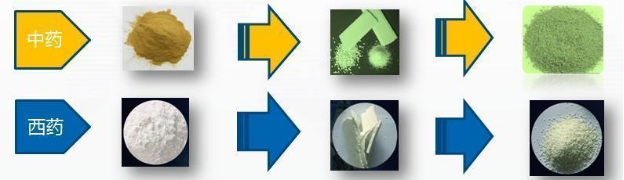

The LGP series Roller Compactor is an equipment that integrates feeding, extrusion, crushing, granulating, and discharging functions. It can directly turn powder materials into granules, especially suitable for granulating of materials that are prone to decomposition or agglomeration when wet or hot. This device is widely used in industries such as pharmaceuticals, food, and chemicals.

Work principle

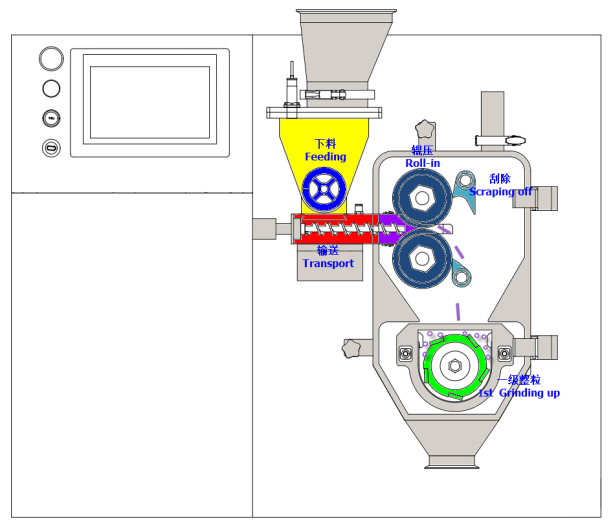

Roller Compactor is a conveying device that transports single or multiple mixed powder materials into a hopper. The powder materials are further transported to the triangular area of the roller through a horizontal screw. The powder is pressed into pieces by a pair of parallel rollers, and then crushed and granulated to granules. Finally, it is vacuum discharged to the Vibro Sifter (optional equipment) to screen out qualified particles within the specified size range.

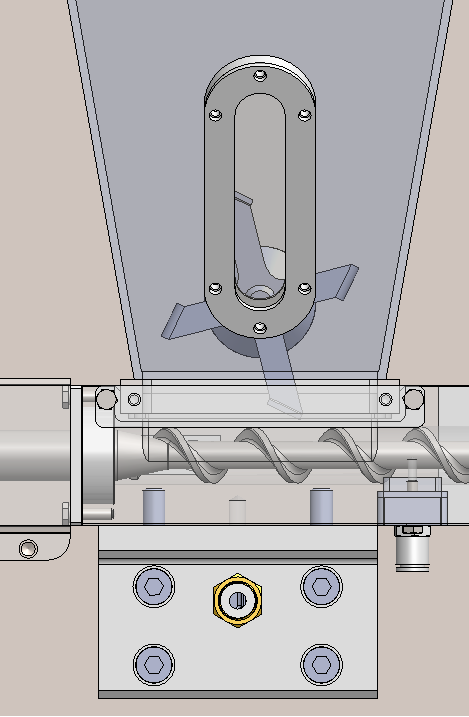

The operation system includes automatic mode and manual mode. In the actual production process, when the system loads the set parameter values (including screw conveying speed, roller pressure, roller speed, roller clearance, etc.), the control system executes various actions of the tablet pressing process according to the process parameters, ensuring uniform feeding and obtaining specific tablet thickness and density. The working principle is shown in the following figure.

Work Principle Diagram

Powder Compaction Behavior Characteristics

Features

1) PLC automatic control, color touch screen human-machine interface is friendly, easy to operate.

2) After the material enters the feeding hopper, it is stirred by the mixing impeller and enters the screw feeder, which is fed by the screw and the rotation speed is continuously adjustable;

3) Two parallel rollers are specially treated to increase loading capacity and strength;

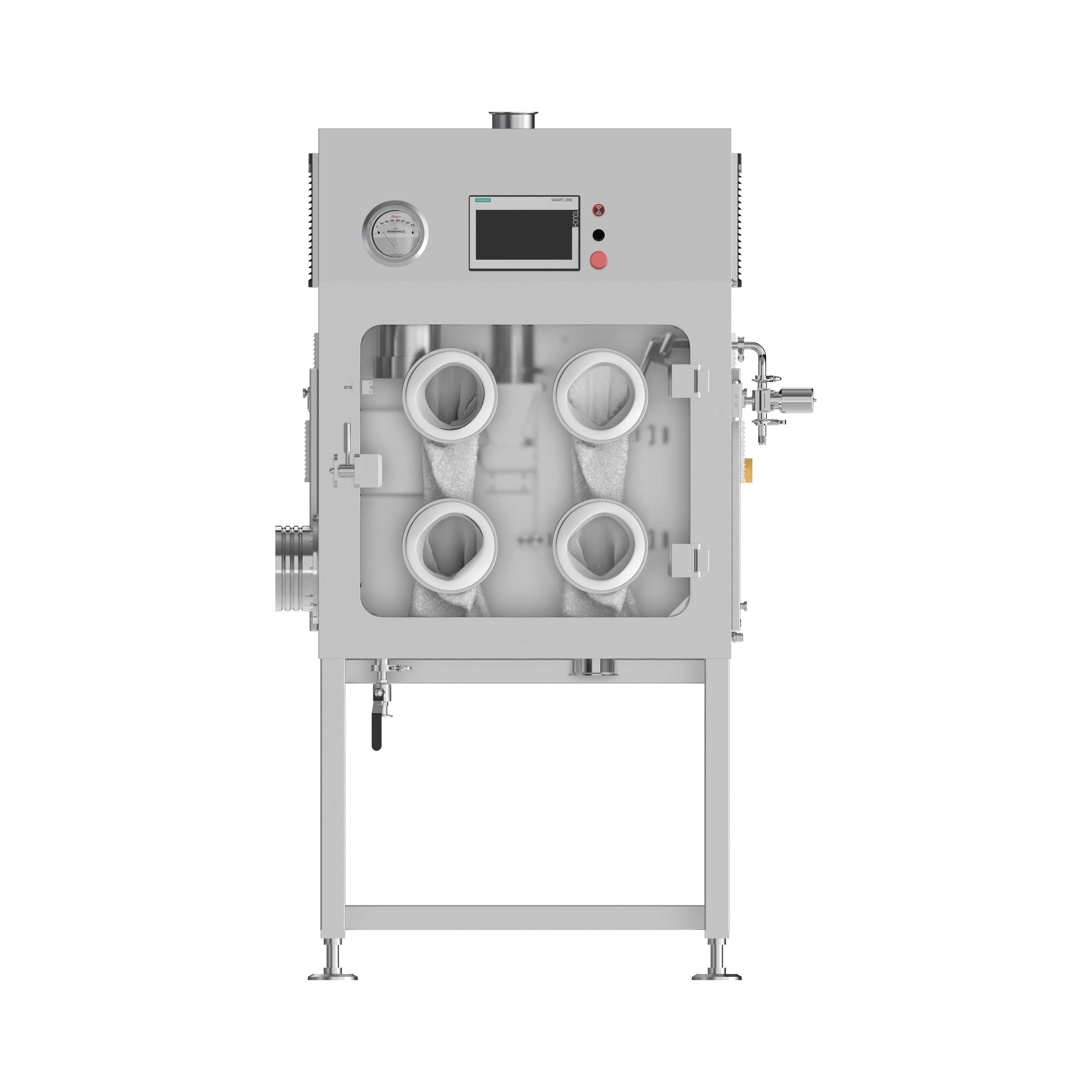

4) The roller chamber is completely closed and its compression is observed through the organic glass panel;

5) The roller adopts water circulation cooling structure, in order to prevent thermal deterioration of special materials;

6) Rollers with different surface shapes can be quickly replaced according to process requirements;

7) The main drive motor (roller) adopts frequency conversion speed regulation, the rotation speed can be continuously adjusted, and has the upper and lower limit control of rotation speed;

8) Parts in contact with the material shall be made of stainless steel or food-grade polymer materials;

9) The pressure applied to the roller and the roller clearance can be displayed and adjusted on the touch screen;

10) The milling device can change the screen according to the need to obtain different mesh number of material granules;

11) By changing the speed ratio between the screw feeding and the roller, granules of different thickness and hardness (or specific gravity) can be obtained;

12) With the setting of machine parameters and working mode, and the function of password protection, failure alarm and help menu;

13) The machine equipped with horizontal twin screw feeding and unique cantilever type design, which improves the range of materials treated and the success rate and yield of granulating;

14) Water-cooled roller, the production of materials will not affect the performance of the material due to temperature rise;

15) The rollers are made of special stainless steel by special process, and its surface has high hardness and wear resistance;

16) The whole machine is of high quality stainless steel construction, all material contact parts are 316L, which fully meets the GMP requirements of drug production;

17) The feeder is designed with a vacuum exhaust port, which can effectively discharge the air in the material when the screw is feeding, so that the feeding is more compact. Unique vacuum exhaust system, does not cause equipment temperature rise.

18) The working area is separated from the transmission area to achieve clean and closed production from powder to granules, effectively preventing dust and cross contamination, and all parts in contact with materials are easy to disassemble and clean.

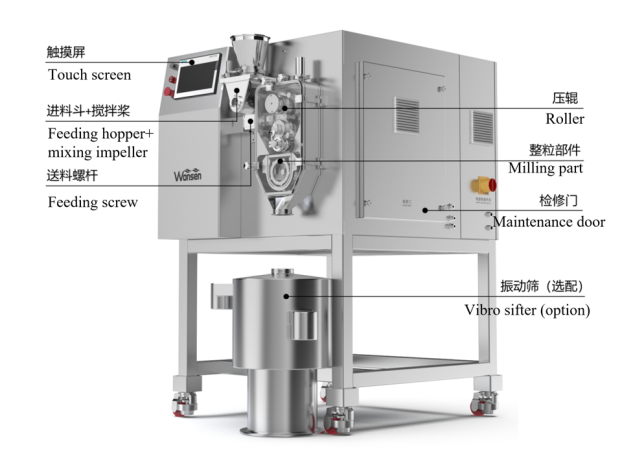

Structure

Technical parameter

No. | Parameter name | Parameter content (LGP-100) |

1 | Roller size (mm) | 100×20 mm |

2 | Granule size (mm) | 0.18-2.0 mm |

3 | Loading capacity (kg/h) ※ | 0.1-15 kg/h(Taking 100-mesh lactose as an example) |

4 | Mixing rotation speed (rpm) | 0-70 rpm |

5 | Screw feeding rotation speed (rpm) | 0-140 rpm |

6 | Roller rotation speed (rpm) | 0-23 rpm |

7 | Granulating rotation speed (rpm) | 0-140 rpm |

8 | Screw feeding motor power (kW) | 0.75 kW |

9 | Roller motor power (kW) | 1.1 kW |

10 | Granulating motor power (kW) | 0.55 kW |

11 | Mixing motor power (kW) | 0.12 kW |

12 | Hydraulic pump station motor power (kW) | 0.55 kW |

13 | Maximum Roll Pressure | 30 kN/cm |

14 | One-time yield (0.18-2.0mm granules)※ | ≥65% |

15 | Final yield※ | ≥98% |

16 | Compressed air pressure (Mpa)※ | 0.4-0.6Mpa |

17 | Compressed air consumption (L/min)※ | 400L/min |

18 | Compressed air tube※ | Φ12*8 |

19 | Reference total weight (kg)※ | 800 Kg |

20 | Reference outline dimension | Please refer to the drawing |