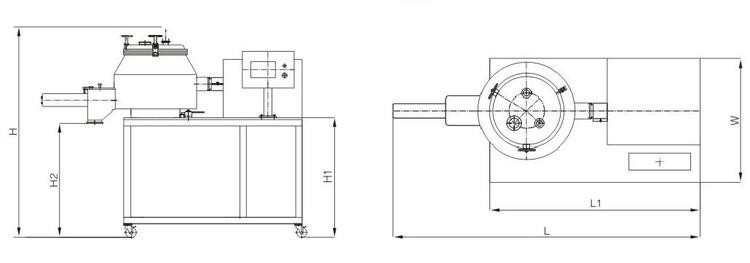

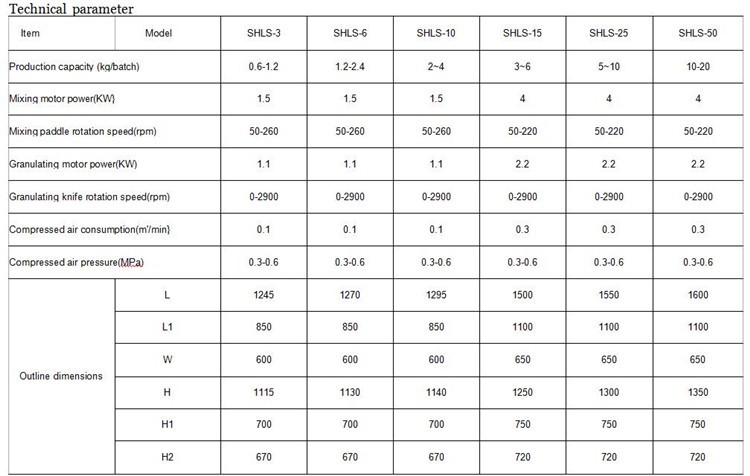

Laboratory rapid wet type granulator or rapid mixer granulator (SHLS Series)

- wonsen

R&D and scale up

Moveable design

Compact structure and space saving

Changeable granulating bowls

Safety interlocking system

Good reproducibility

Fully meet FDA, cGMP, GMP

Labratory small volume rapid mixer granulator or rapid mixer granulator

Application

The machine is a process machine widely applied for solid preparation production in the pharmaceutical industry. It has such functions as mixing, granulating, etc. It is widely used in such industries as medicine, food, chemical industry, etc.

Work Principle

The powder materials are fed into the mixing vessel manually. Through rotation and push by the mixing paddle at the bottom, they first move under a fluidizing status and get sufficient mixing. Then the adhesive is injected through the pressure spray gun to turn the dry powders into wet and soft materials. Meanwhile, they are made into even wet granules under the double actions of the mixing paddle and the high-speed cutter on the side wall.

Features

1.The whole machine is made of high quality stainless steel and is convenient to move with castors.

2.The mixing and granulating procedure can be completed in one step with the materials mixed and granulated in the closed 3.mixing barrel.

4.lt adopts PLC control. The mixing and granulating motors are subject to variable frequency speed adjustment. All operations can be carried out automatically or manually.

5.It is provided with interlocking protection device to ensure safer operation.

6.It is equipped with printer to automatically print all process parameters, with the original records conforming to the actual ones.

Part of Production & Inspection Equipment

Our Services

1.Your Enquiry or questions will reponse once we receive it!

2.Providing technical data,high-definition pictures,flow chart etc.

3.Supply the validation documents and certificates.

4.OEM/ODM is available.

5.Long-term after-sale service,door-to-door service and corporate training

Why choose us:

1.Specialized in designing, developing and manufacturing.

2.Above 130 National patents,national and provincial technology innovation awards

3.Provincial Pharma Equipment Engineering Technology Research Center

4.National High-Tech,National Pharma Equipment Industry Association,Provincial new special expertise Enterprises

5.Modern production workshop and production line of high-end manufacturing equipment

6.Professional and efficient after-sales service management

7.Meet ISO9001 and CE

8.OEM/ODM available

Our Company View

Alibaba Assessed Supplier

FAQ

1.How long for the delivery?

Within 45 days after receiving the deposit.

2.What's the payment terms?

T/T, L/C,Cash,West union etc.

3.OEM and ODM?

Yes

4.How long is the warranty period?

One year after shipment

Welcome to Contact us