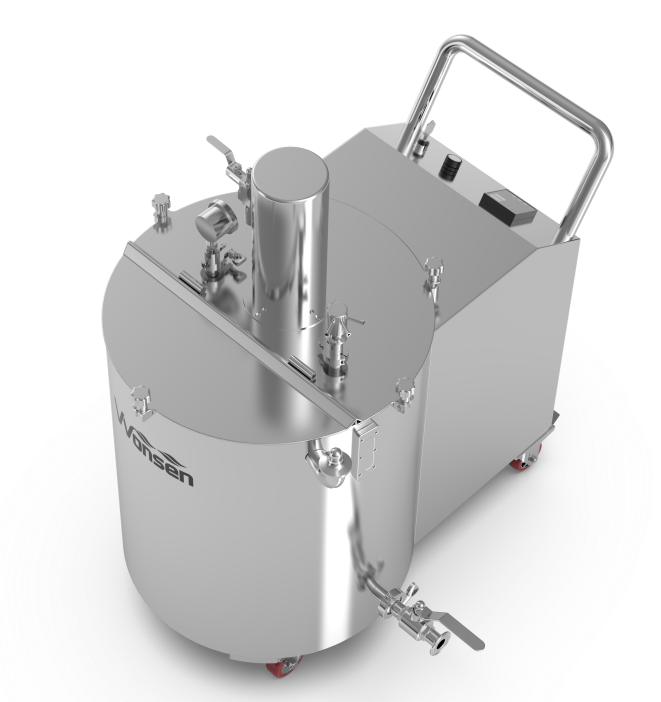

JBT-A series Single Layer Solution Mixing Tank

- Wonsen

- China

- 120 days

- Strong

The main body of JBT-A series Single Layer Solution Mixing Tank is made of stainless steel, with a mirror-polished inner surface and a hairline/sandblasted outer surface, in compliance with GMP requirements.

JBT-A series Single Layer Solution Mixing Tank

Introduction

The JBT-A series Single Layer Solution Mixing Tank is designed with devices such as a trolley and a mixing paddle, and it has functions such as mobility and mixing. The mixing paddle speed is adjustable and can be used for the preparation and mixing of various liquids or slurries. According to customer requirements, it can be used in conjunction with equipment such as Coating Machine, Fluid Bed Granulator, and Mixer Granulator for the storage and mixing of coating liquid/adhesive, etc. It is widely used in the pharmaceutical, food, beverage, chemical and other industries.

Feature

1) The slurry is added through the flip cover. After the cover is locked, the power is turned on. The mixing paddle, driven by a pneumatic motor, rotates in a fixed direction to thoroughly mix the slurry.

2) The structure is rationally designed, with simple operation, convenient use, and reliable safety.

3) It is equipped with 2 fixed and 2 movable casters, as well as a handle, making it easy to move.

4) The mixer is powered by compressed air, with a stable speed and stepless speed regulation.

5) The main body is made of stainless steel, with a mirror-polished inner surface and a hairline/sandblasted outer surface, in compliance with GMP requirements.

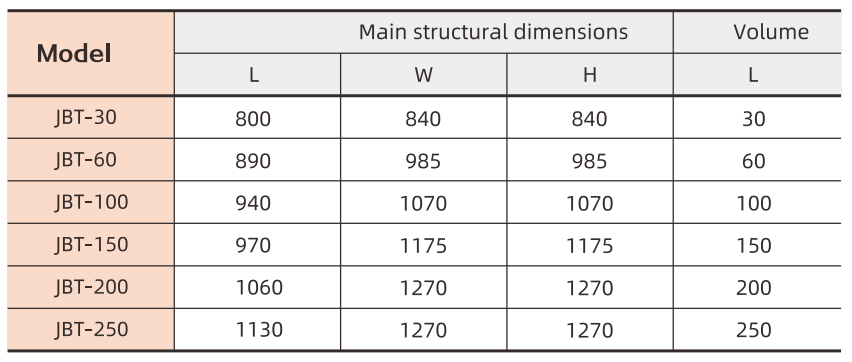

Technical parameter

For specific technical parameters, please leave a message for inquiry.