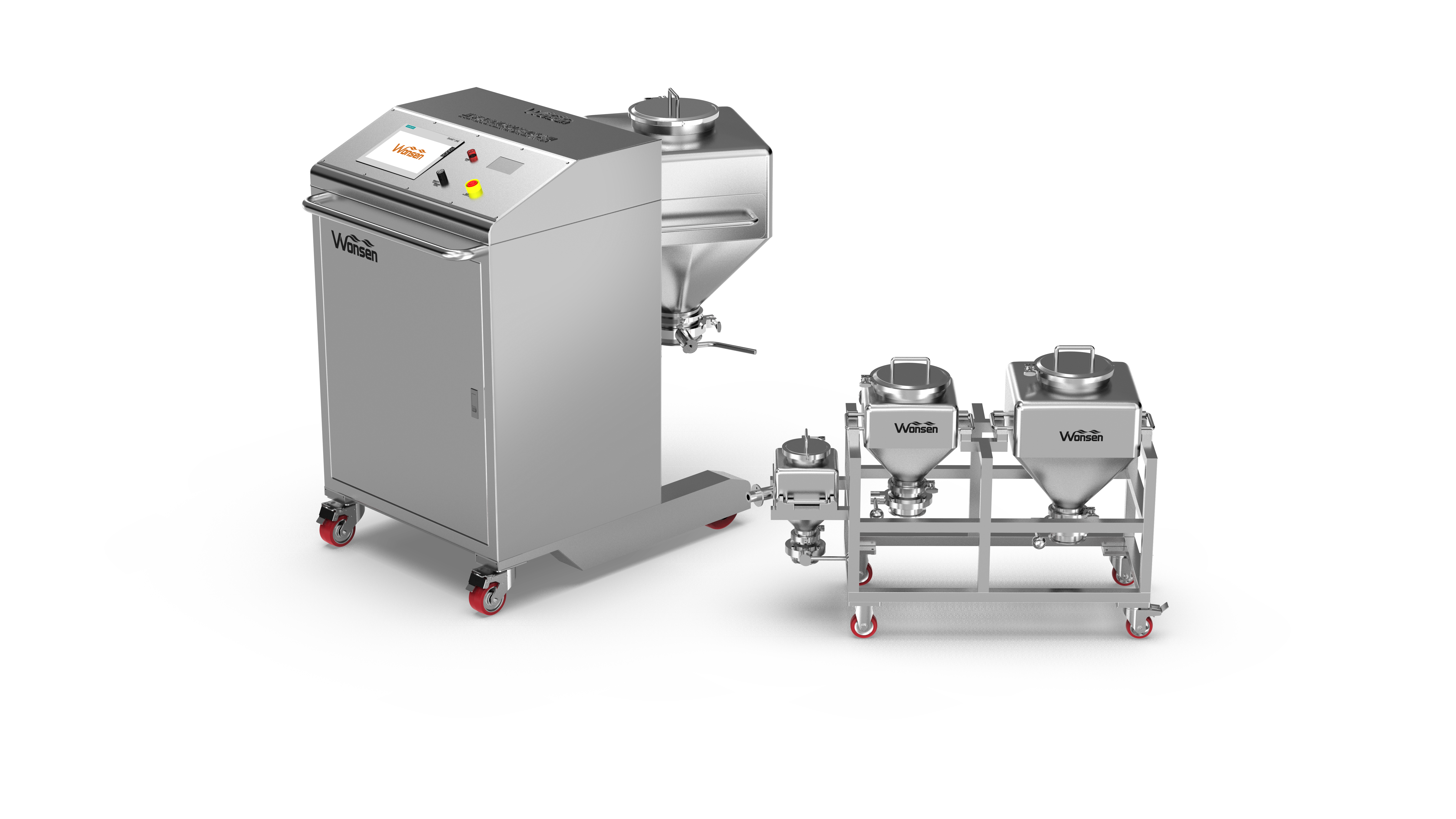

HLS-15 Lab Bin Blender Mixer Used for the Tests of Mixing Different Components

- Wonsen

- China

- 120 days

- Strong

The machine is mainly used for the tests of mixing different components of dry powders with dry powders, granules with granules, or powders with granules in laboratories.

HLS-15 Lab Bin Blender Mixer Used for the Tests of Mixing Different Components

Application

It is mainly used for the tests of mixing different components of dry powders with dry powders, granules with granules, or powders with granules in laboratories. It is an ideal machine for exploring the best process parameters in material mixing, and an advanced mechanically and electrically integrated experimental machine.

Work principle

Put the materials into the closed mixing barrel. As the symmetrical axis of the hopper forms an included angle with the rotation axis, different components of materials will move in the closed hopper, producing strong turning, diffusing and shrinking actions and achieving the best mixing effect.

Feature

1) With novel design, compact structure and beautiful appearance, the machine can reach mixing evenness of 99% and volume loading coefficient of 0.8.

2) It has such features as high rotation height, stable running, reliable performance and convenient operation.

3) The inner and outer walls of the barrel are subject to mirror polishing with easy discharging and easy cleaning and without any dead corners and cross contamination, meeting GMP requirements.

4) A square conical shape with lid and discharge port.

5) Internal surfaces: mirror polishing Ra≤0.2μm

6) External surfaces: brushed or sand blasting Ra≤0.8μm

7) No hidden surfaces/dead corners/joins: Materials at all the welding points undergo cut chamfering and the double-side argon arc welding is adopted. All seams are ground flush.

8) The inlet of the bin is made by way of tension. The upper cover is punched through the use of special moulds and the "0" seal ring of silicon rubber is embedded.

9) A stainless steel butterfly valve with anti-operation device ensures the leakage of fine powder during blending is zero.

10) The material of leakage proof valve is 304.

Bin lid

butterfly valve

Internal surface

Technical parameter

No. | Name | Parameter |

1 | Volume | 15L |

2 | Effective volume | 12L |

3 | Charging coefficient | 30%~80% |

4 | Max load weight | 7.5kg (based on bulk density 0.625 kg/L,if bulk density is bigger, then capacity will also larger) |

5 | Main shaft speed | 3-30 rpm |

6 | Motor power | 0.37kW |

7 | Power supply | 3PH/380V/50Hz |

8 | Referenced weight※ | 180kg |

9 | Referenced dimension size※ | According to the actual drawing |

10 | "※" is a reference value, consumption, yield, net weight of equipment, dimensions and other standards for reference only, the actual parameters and materials, configuration, process related. | |