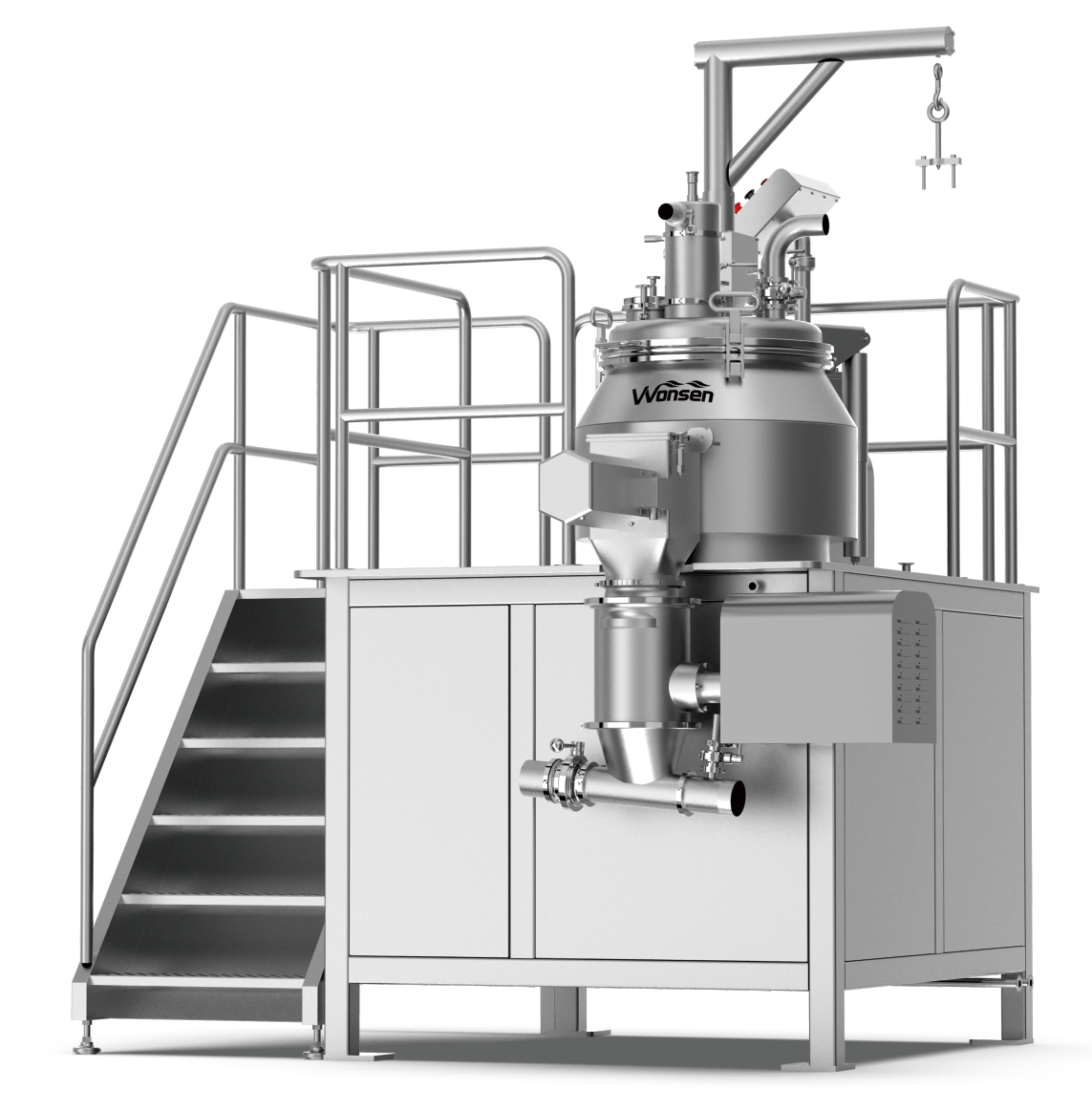

High Shear Mixer Granulator: A Key Wet Process Granulator for Efficient Granulation

- Wonsen

- China

- 120 days

- Strong

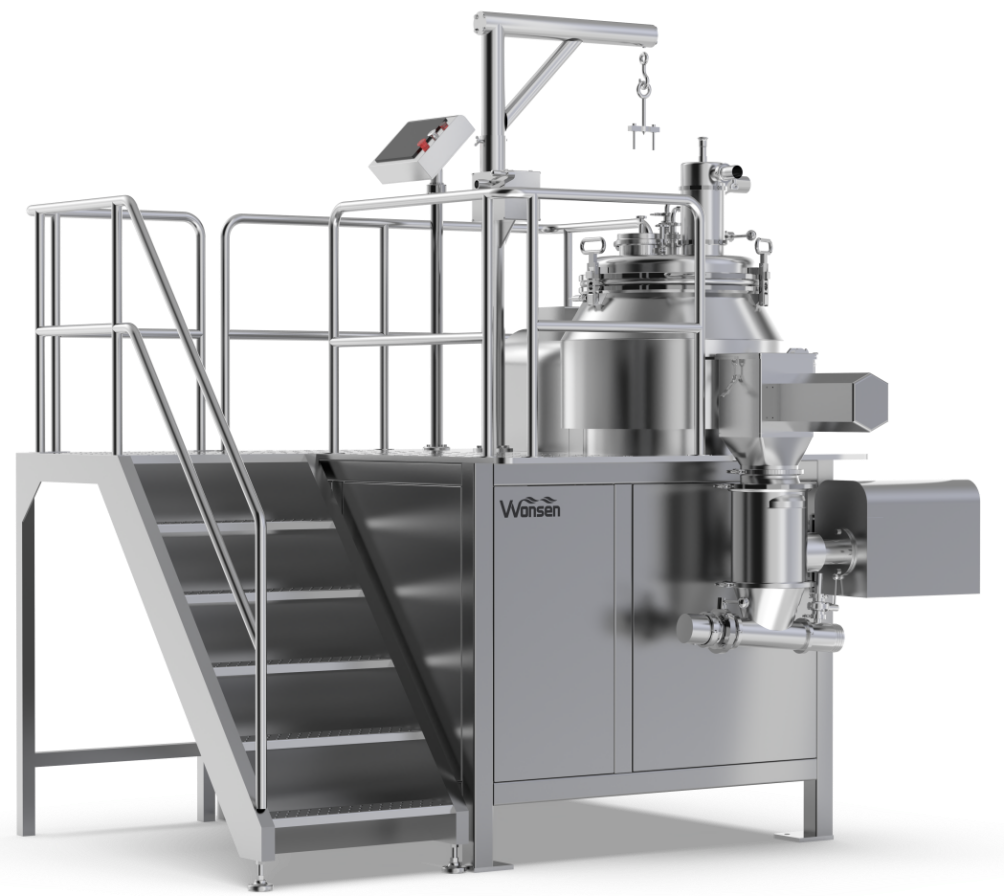

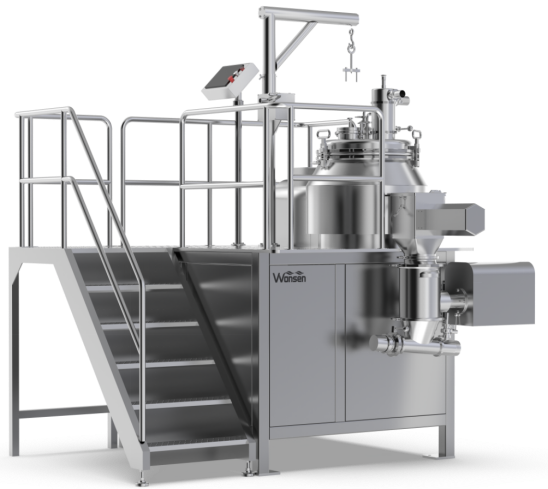

▲Higher working platform, better for connecting with FBD to discharge

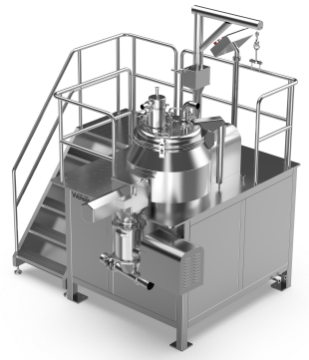

▲Compact structure

▲Tangential impeller

▲WIP system

▲Good reproducibility

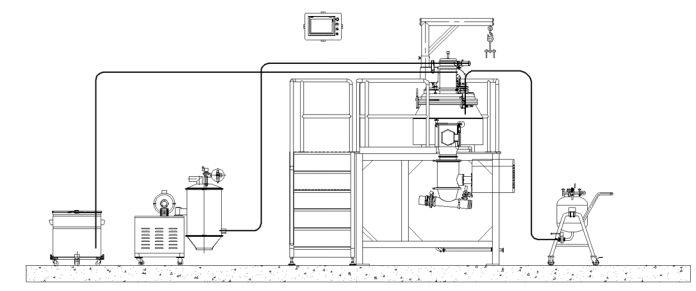

▲Can connect with fluid bed dryer to form a fully closed granulating production line

▲Fully meet FDA,CGMP,GMP

▲Control system can optionally complying 21CFR Part11 requirements

High Shear Mixer Granulator: A Key Wet Process Granulator for Efficient Granulation

Introduction

The rapid mixer granulator is a commonly used process equipment in solid dosage form production within the pharmaceutical industry, integrating multiple functions such as mixing and granulation. It is widely applied in pharmaceuticals, food, and chemical industries. This equipment achieves mixing and granulation in a single step, delivering high-quality granules without cross-contamination, and complies with GMP requirements.

Depending on the downstream equipment connected in the production process, the wet granulation equipment can be customized as either the SHLG high shear mixer granulator or the SHL rapid mixer granulator.

Work principle

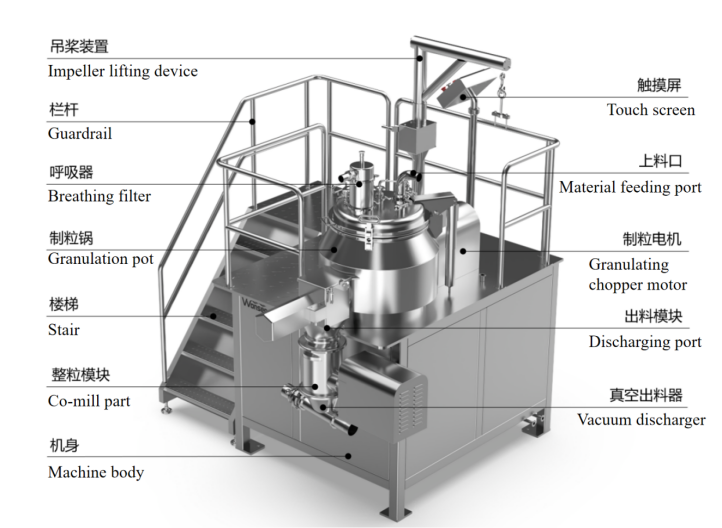

The equipment adopts PLC control and frequency conversion speed regulation. All operations can be automatically completed according to the process parameters set by the user, and all process parameters can be printed, with authentic and reliable original records. During operation, materials are fed into the mixing vessel via a vacuum feeder/lifting feeder/manual feeding. The powder is mixed by the stirring paddle; with the injection of the adhesive, the powder is gradually wet and the shape of the material changes. The granulation knife located on the horizontal shaft of the pot wall rotates simultaneously with the stirring paddle to generate a vortex, enabling the materials to be fully mixed, turned over and collided. When the turned-over lumpy materials pass through the area of the high-speed rotating granulation knife, they are fully crushed into granules by the granulation knife. At the same time, the granules are mutually extruded, collided, rubbed, sheared and kneaded in the three-dimensional movement, making the granules more fine and uniform.

Features

1) Complete set of electrical components from internationally renowned brands, adopting Siemens PLC and touch screen, and Schneider frequency converter for speed adjustment;

2) The granulation knife adopts a Christmas tree-shaped structure, the stirring paddle adopts a new three-leaf structure, and a combined seal of mechanical seal and air seal is used;

3) Innovative sprocket drive, which improves stress deformation caused by machining tolerances and facilitates installation and disassembly;

4) Equipped with a stirring paddle lifting device to ensure production safety (equipped for rapid mixer granulator with a volume of 200L and above);

5) The granulation cylinder is equipped with a power-assisted opening device, which saves labor and ensures production safety (equipped for rapid mixer granulator with a volume of 100L and above);

6) The cylinder cover and cylinder body, as well as the discharge port and rapid mixer granulator, adopt airbag seal design with good sealing effect; when the sealing pressure is insufficient, interlock control will stop production and give an alarm;

7) The stirring paddle, granulation knife, and granulating knife (with the granulating knife) are added with closed-loop speed control, which detects the actual speed of the shaft and displays it on the screen; the speed is accurate, not affected by load or motor speed error; it also has the function of monitoring abnormal speed and alarming in case of coupling failure;

8) The main machine is equipped with a conical slurry adding hopper and a manual ball valve; an optional pressure slurry adding tank + spray gun (or solution mixing tank + peristaltic pump + spray gun) can be configured to realize automatic slurry adding with no residue and accurate slurry adding measurement (with a flow meter or ultra-low platform scale);

9) The main machine is equipped with a vacuum feeding interface, which can be connected to a vacuum feeder or a vacuum source to realize automatic feeding;

10) Reserved cleaning pipelines, which can be connected to the water source of the cleaning machine for CIP cleaning;

11) The mixing and granulation time meets the process requirements of corresponding solid preparations (generally 6-10min/batch);

12) The granulation yield is >99%;

13) The automatic production and automatic cleaning formulas of the equipment support variable process control, and the process parameters of each stage can be set independently to meet the needs of customers' customized processes;

14) Can be configured with electronic signature, data storage and audit trail functions, and can print process data;

15) Optional time, current or torque as the end-point determination;

16) The equipment has passed the EU CE certification;

Structure

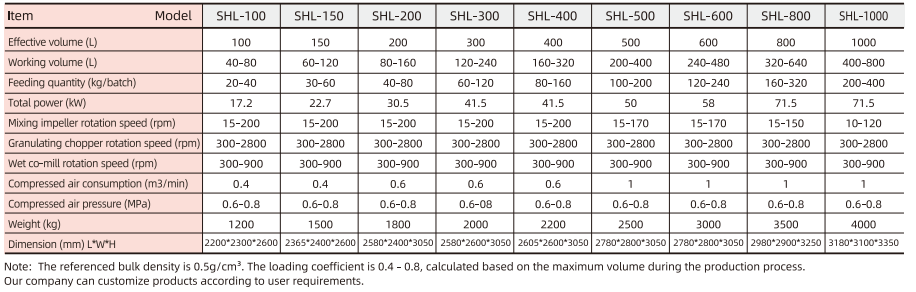

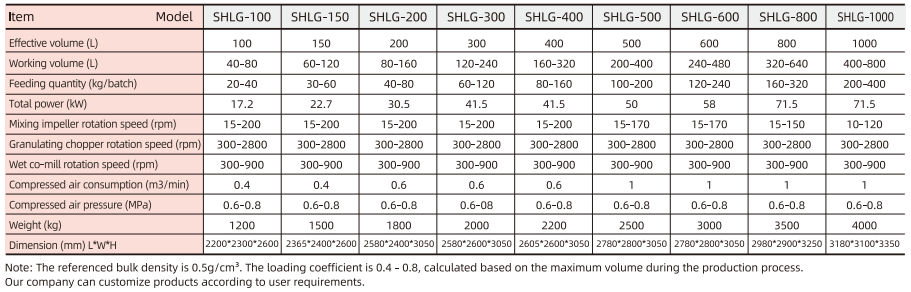

Technical parameter