BGB-S Series Lab Coating Machine Suitable for R&D Scale with Integrated Design

- Wonsen

- China

- 120 days

- Strong

▲Suitable for R&D scale

▲Interchangeable coating pans can be replaced according to the different batch size

▲Easy operation of replacing the interchangeable coating pans

▲With compact and integrated structure, air intaking at the clean area, saving space

▲With movable heavy duty wheels with brake

▲lt adopts HMl and PLC auto control system, can optionally comply 21 CFR Part 11 requirements

BGB-S Series Lab Coating Machine Suitable for R&D Scale with Integrated Design

Introduction

The BGB-S series lab coating machine is mainly for small-batch coating experiments in pharmaceutical and food industries. It can coat materials of multiple specifications with one machine, greatly boosting its research practicality.

Meeting GMP requirements, it is a kind of mechanically and electrically integrated coating equipment with high efficiency, energy conservation, good safety and good cleanliness for organic film coating, water soluble coating, dripping pill coating, sugar coating, chocolate and candy coating of tablets, pills, candies and other special parts.

Work principle

In the rotating drum, uncoated tablets move along a trajectory driven by stirring blades and guide plates, mixing with sprayed coating solution. Filtered, heated air is delivered into the drum from the upper right via a fan, passes through the material, and is filtered before exiting from the lower left. This ensures rapid, uniform drying of the coating medium on the tablets, forming a firm, smooth surface film.

Features

1) Integrated Design: Compact structure for easy mobility, installation, and maintenance. Operates with power and gas supply, featuring high efficiency, energy savings, and user-friendly operation.

2) Interchangeable Coating Pans: The coating pan can be quickly and easily swapped to match batch sizes, with tool-free disassembly and installation. A single machine supports 2-3 pans of varying capacities, addressing challenges in R&D labs such as frequent product changes, small batch sizes, and high-vale materials.

3) Open-Front Door with Airbag Seal: Front door with full-open design and unique airbag sealing structure

4) Optional Inline Sampling System: Enables closed-loop sampling without process interruption.

5) Gentle Tablet Handling: Smooth cone-to-screen transition in the coating pan prevents tablet damage.

6) Closed-loop pan speed control: Actual shaft speed is detected, displayed, and precisely maintained—unaffected by load, motor errors, or coupling failure. Abnormal speed triggers alarms.

7) Patented deflector: Ensures tablet flowability while preventing damage.

8) Active Negative Pressure Control: Ensures parameter consistency.

9) Top-inlet and bottom-exhaust design: Increases coating solution utilization by 5-10%.

10) Air handling system: Inlet air filtration: Grade H13; Exhaust air filtration: Grade F9. Meets national emission standards.

11) Precision Control: Airflow accuracy up to ±5%, negative pressure accuracy up to ±15 Pa, and supply air temperature accuracy up to ±1.5°C (with optional sensors).

12) Advanced Control System: Features audit trail, data logging, and trend graph functions . (With optional smart line or industrial screen)

13) Customizable Recipes: Automated production recipes: Support variable process control with independent parameter settings for each stage, meeting customized process requirements.

14) Compliance: Meets EU CE certification standards, and complies with new GMP, CGMP, and FDA regulations.

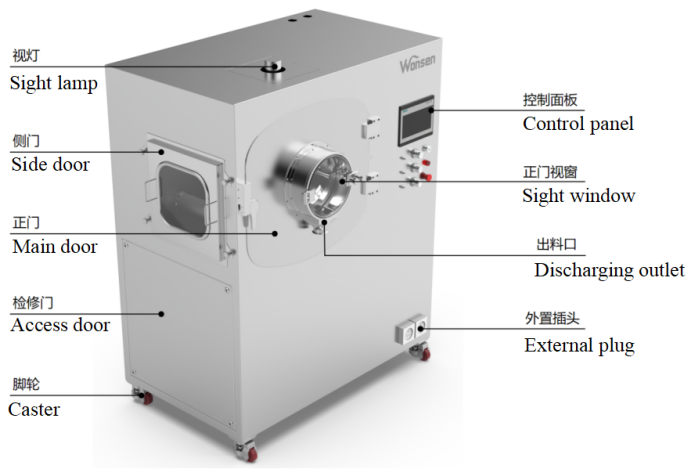

Structure

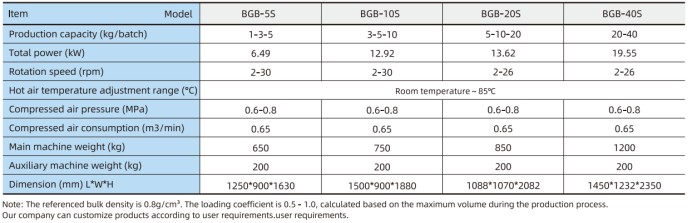

Technical parameter