Wonsen Warehouse Management System Efficiently Integrates Resources, Accurately Controls Inventory

Wonsen Warehouse logistics management has achieved automation, dataization, intelligence, and integration.

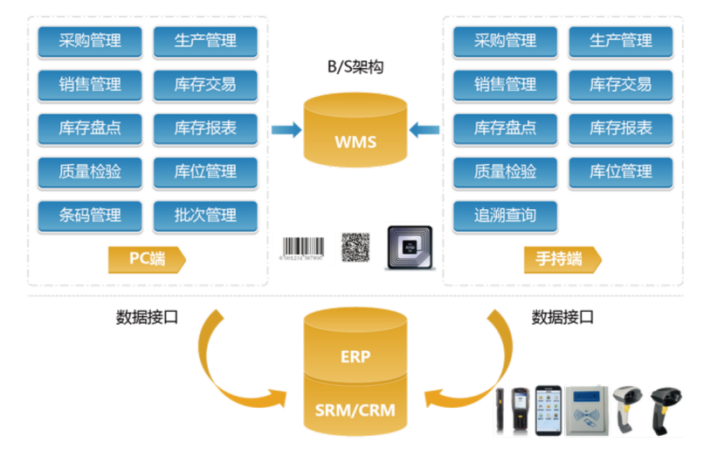

Wonsen WMS system can achieve the full - process management of inbound, inventory, outbound and goods tracking. With advanced barcode, RFID technology and AI algorithm technology, it can realize the efficient inbound and outbound management of goods and material traceability. It can also realize functions such as inventory checking, inventory inquiry and inventory warning, to achieve precise management of inventory and avoid overstock and stock - out. Through intelligent algorithms and data analysis, it can optimize the layout and operation process of the warehouse, and improve the utilization rate and efficiency of the warehouse. The system can also be integrated with the AGV intelligent scheduling management system. According to the material inbound and outbound and transfer tasks, it can automatically plan the material transfer plan and route, and dispatch the AGV trolley to realize the automated material transfer.

Advantages of Wonsen Intelligent Solid Dosage Form Digital Factory Solution

(1)Depth of Technology

A diversified professional team integrating automatic control, software development, and project management, with over 40 software copyrights and patents. The system is fully self-developed and can be customized according to requirements.

(2)Industry Experience

15 years of experience in the pharmaceutical, food, and other health-related industries, with deep integration of software and hardware.

(3)Industry Maturity

Digitalization level reaches Level 7. Wonsen is a benchmark enterprise for intelligent manufacturing in Jiangxi Province, one of the first "Lighthouse" enterprises in Jiangxi, and one of the first industrial internet solution providers in Jiangxi. It provides a solid backing for customers' digital transformation.

(4)Customized Design

Exclusive customized design for scenarios such as solid dosage forms, raw materials, food, and health products, closely matching the actual usage scenarios of users.

(5)Delivery Assurance

Full-service capability covering consultation, design, and implementation of intelligent process equipment, weak electrical system integration, information systems, and system validation.

- Rapid mixing granulator

- SHLG high shear mixing granulator

- SHL wet type mixing granulator

- SHLS lab wet type mixing granulator

- Top Drive Wet Type Rapid Mixer Granulator

- Drying machine

- FG Fluid bed dryer

- FL Fluid bed granulator

- DPL Multi-functional fluid bed dryer-granulator-coater

- DPLS Multi-functional fluid bed dryer-granulator-coater

- Mixer / bin blender

- ZTH Auto lifting mixer

- HLT Single-column lifting mixer

- HLS Lab scale mixer

- HF Square cone mixer

- Vertical Bin Blender

- Horizontal ribbon mixer

- High efficiency coating machine

- BGB-D High efficient coating machine with CIP

- BGB-C High efficent coating machine

- BGF New Coating machine with interchangeable pans

- BGB-F Lab coating machine

- BGB-M Containment coating machine